System and method for reducing emission of low-concentration combustible gas

A low-concentration, gas-based technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve problems such as waste of fuel resources, difficulty in direct combustion, environmental pollution, etc., to reduce surface carbon, reduce operating costs, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

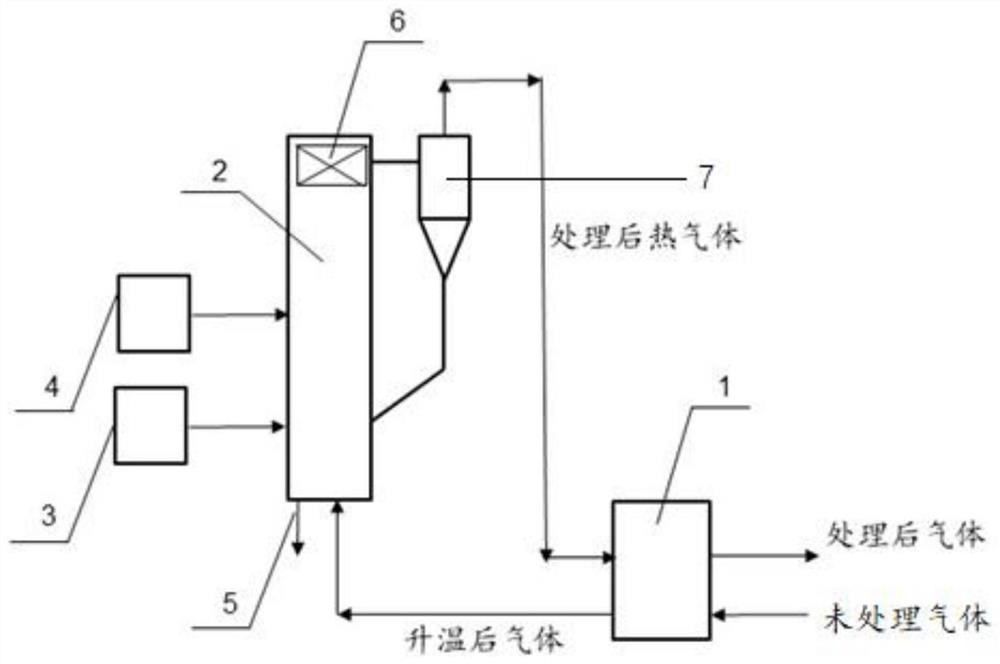

Image

Examples

Embodiment 1

[0105] Untreated gas for coal mine ventilation with a treatment capacity of 430,000Nm 3 / h, wherein the methane concentration is 0.8%, using a circulating fluidized bed reactor, and the catalyst material is waste copper slag. The gas heat exchanger adopts a rotary heat exchanger. The untreated gas with a temperature of 25°C is sent into the gas heat exchanger, and exchanges heat with the treated hot gas with a temperature of 450°C to form a heated gas with a temperature of about 410°C. After the temperature rises, the gas enters the circulating fluidized bed reactor. The catalyst particles are added through the catalyst feeder and recycled in the reactor, and the waste catalyst particles are discharged from the system through the discharger. After the temperature rises, the low concentration of methane in the gas is oxidized under the catalytic action of the catalyst particles and releases heat. After the temperature rises, the gas is transformed into a treated hot gas. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com