Design method and device for pool type liquid metal reactor test system

A design method and test system technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as large errors in heat transfer analysis methods, reduce time costs and economic costs, and achieve high reliability of results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0220] The invention provides a method for designing a pool type liquid metal reactor test system. The design method uses the π theorem and the similarity principle to dimension the test system parameters and control equations on the basis of a given inert protective gas space heat transfer model. Analysis and equation analysis, including:

[0221] Determine the test system parameters, the test system parameters include geometric structure parameters, thermophysical parameters and working condition parameters;

[0222] Determine the dimension of each parameter, and screen out the basic parameters for dimensional analysis;

[0223] Use the π theorem to conduct dimensional analysis on the parameters of the test system to obtain dimensionless numbers;

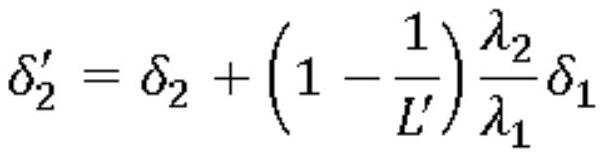

[0224] Using the principle of similarity to analyze the control equations of the test system to obtain dimensionless numbers; the model control equations include continuity equations, momentum equations, energy equations, inert p...

Embodiment 2

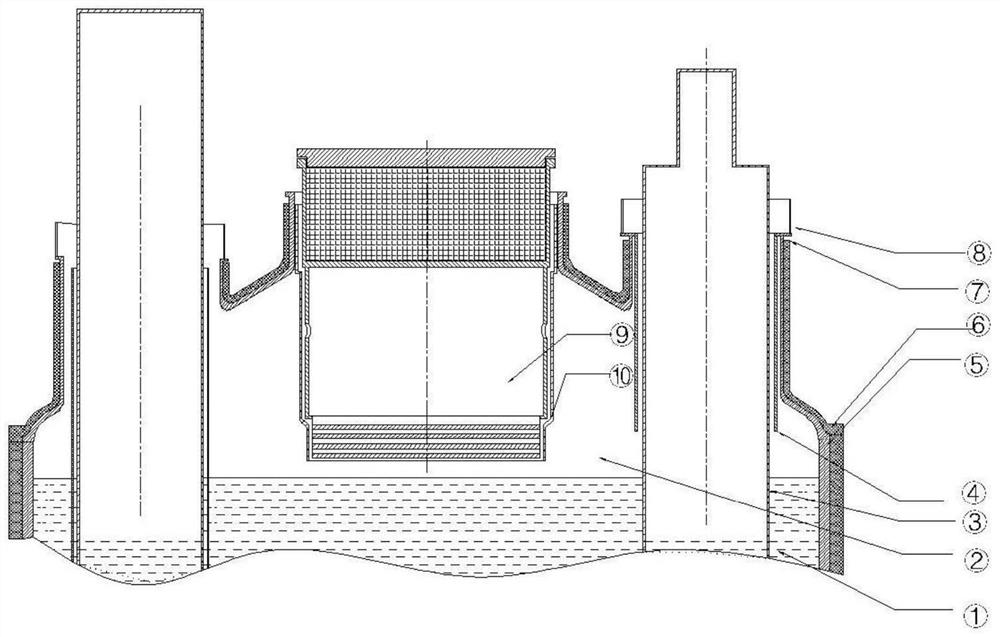

[0385] The test device consists of a shell with an open top, a top cover set at the opening of the shell, and an inert gas loader with adjustable gas supply pressure in the air chamber. The internal space formed by the shell and the top cover is divided into a test medium storage space And the air chamber (inert gas accommodation space) located above the test working fluid accommodation space; the top of the top cover is provided with an opening, and a rotating shielding plug is provided at the opening of the top of the top cover and a sleeve is set on the outer wall of the rotating shielding plug. The cock protective sleeve has an air gap between the rotary shielding plug and the cock protective sleeve; it includes two through supports, the top cover is fixedly connected with the through supports and the heat preservation piece is sleeved on the outer wall of the through supports.

[0386] The heat transfer test system of the above-mentioned pool-type liquid metal reactor is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com