Sulfur-loaded hollow nano polyhedron octasulfide nine cobalt/carbon fiber composite material and preparation method and application thereof

A composite material and carbon fiber technology, applied in the direction of positive electrode, active material electrode, structural parts, etc., can solve the problems of poor conductivity, short service life, low battery cycle performance, etc., and achieve stable performance, low requirements for equipment, and restraint The effect of the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

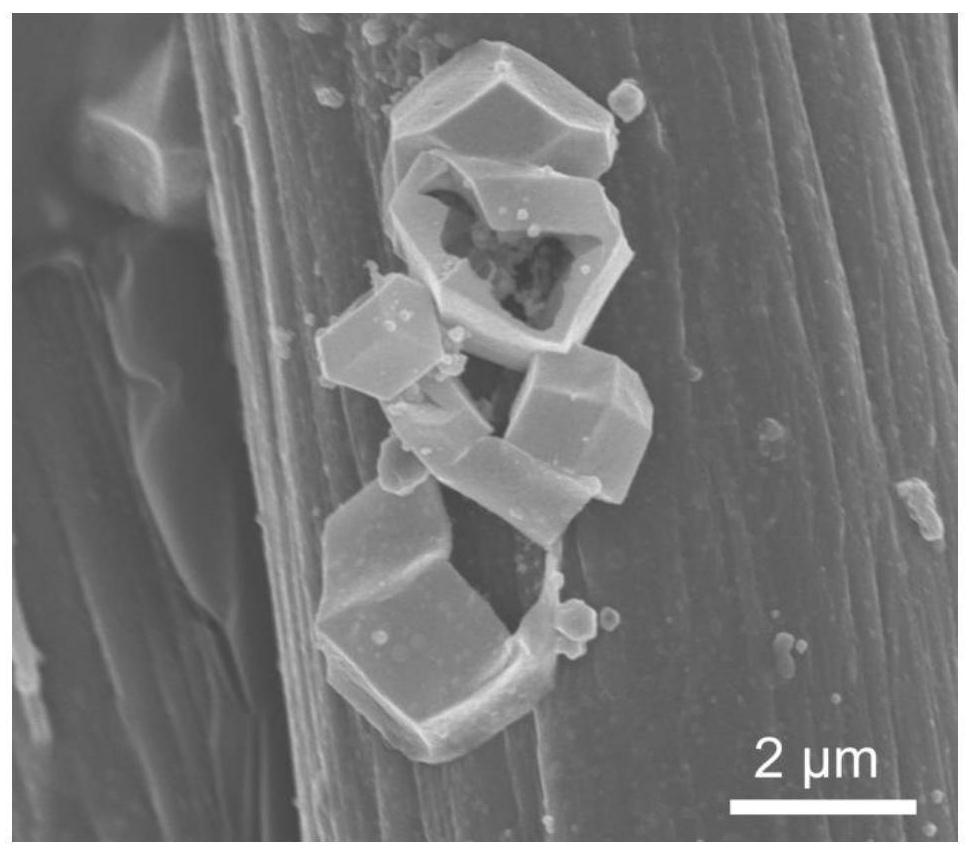

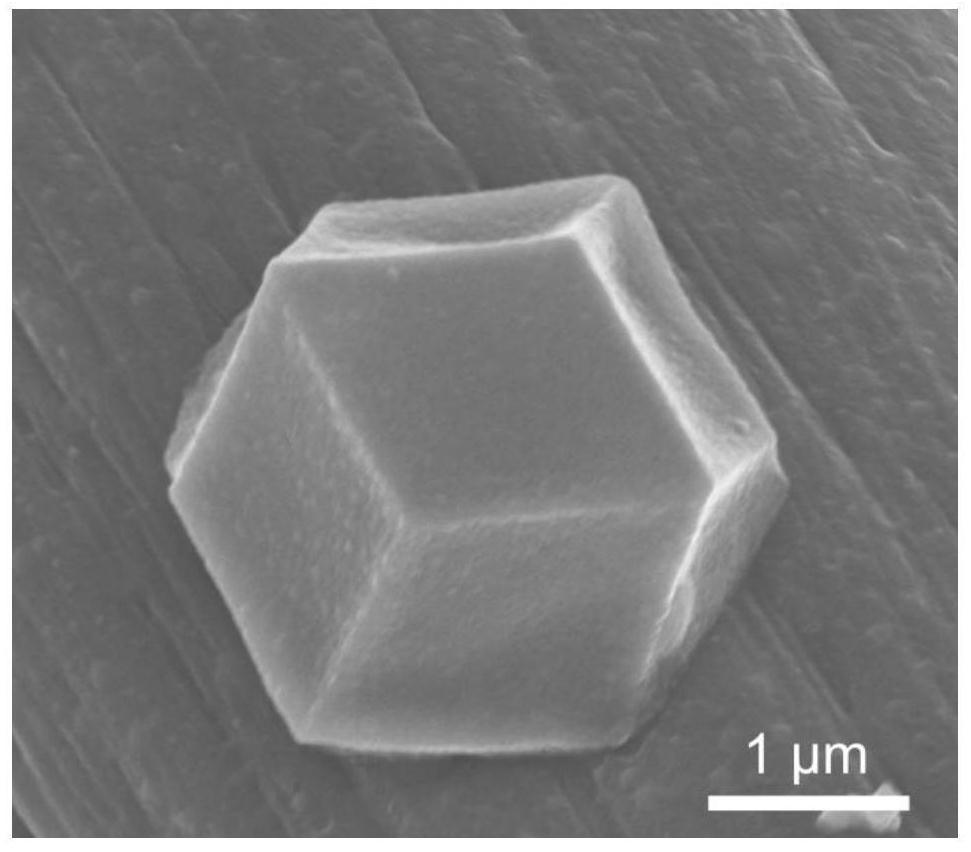

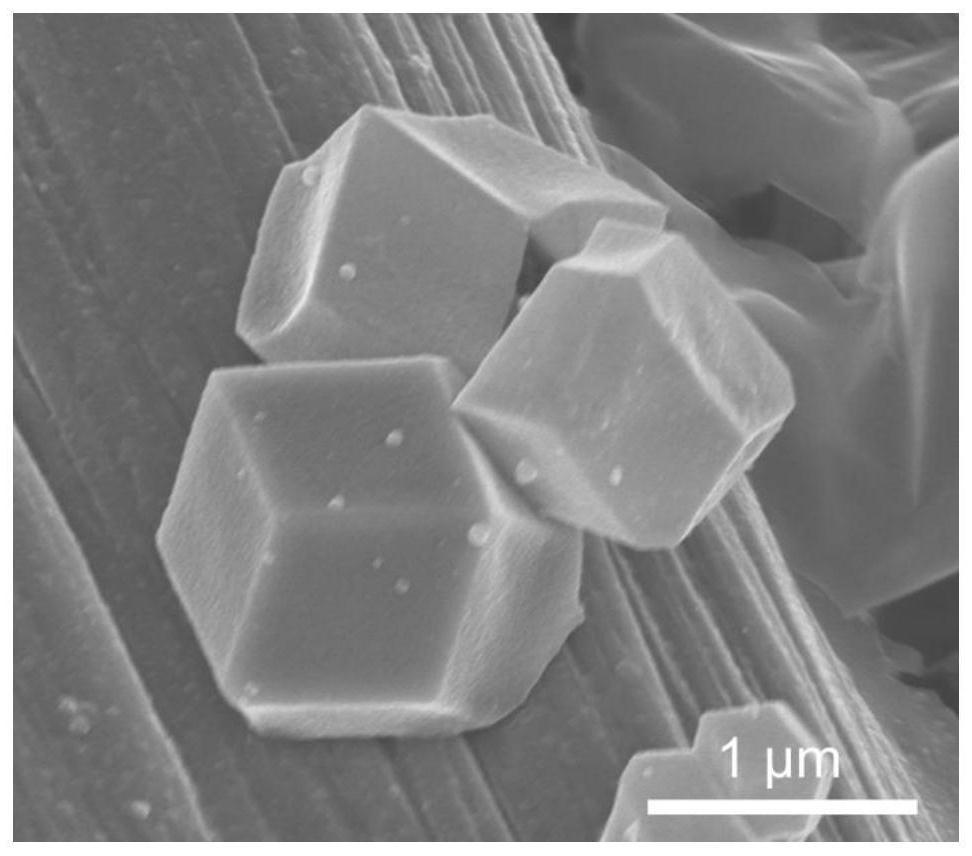

[0046] In this embodiment, the preparation method of the hollow nanopolyhedron octahedral cobalt octasulfide / carbon fiber composite material loaded with sulfur is as follows:

[0047] 1) Dissolve 0.8g of cobalt nitrate hexahydrate in 20mL of methanol to obtain solution A;

[0048] 2) 0.8g of 2-methylimidazole was dissolved in 20mL of methanol to obtain solution B;

[0049] 3) Pour solution B into solution A quickly, stir for 30 seconds, put in carbon fiber cloth and soak for 12 hours, the mass ratio between carbon fiber, cobalt nitrate hexahydrate and 2-methylimidazole is 1:60:70, take out carbon fiber cloth, washed with ethanol, and dried at 50°C for 18 hours to obtain a ZIF-67 / carbon fiber composite material;

[0050] 4) Put the ZIF-67 / carbon fiber composite material prepared in step 3) into 0.04mol / L thioacetamide ethanol solution for hydrothermal reaction, the mass ratio of ZIF-67 / carbon fiber composite material to thioacetamide The ratio is 1:20; the temperature of hydr...

Embodiment 2

[0053] In this embodiment, the preparation method of the hollow nanopolyhedron octahedral cobalt octasulfide / carbon fiber composite material loaded with sulfur is as follows:

[0054] 1) 1.2g of cobalt nitrate hexahydrate was dissolved in 20mL of methanol to obtain solution A;

[0055] 2) 1.0g of 2-methylimidazole was dissolved in 20mL of methanol to obtain solution B;

[0056] 3) Pour solution B into solution A quickly, stir for 3 minutes and mix, put into carbon fiber cloth for soaking reaction for 24 hours, the mass ratio between carbon fiber, cobalt nitrate hexahydrate and 2-methylimidazole is 1:60:70, Finally, the carbon fiber cloth was taken out, washed with ethanol, and dried at 65°C for 6 hours to obtain a self-supporting ZIF-67 / carbon fiber composite material;

[0057] 4) Put the ZIF-67 / carbon fiber composite material prepared in step 3) into the ethanol solution of 0.02mol / L thioacetamide for hydrothermal reaction, the mass ratio of ZIF-67 / carbon fiber composite mat...

Embodiment 3

[0060] In this embodiment, the preparation method of the hollow nanopolyhedron octahedral cobalt octasulfide / carbon fiber composite material loaded with sulfur is as follows:

[0061] 1) 1.4g of cobalt nitrate hexahydrate was dissolved in 20mL of methanol to obtain solution A;

[0062] 2) 1.4g of 2-methylimidazole was dissolved in 20mL of methanol to obtain solution B;

[0063] 3) Pour solution B into solution A quickly, stir for 1 min, and put it into carbon fiber cloth for soaking reaction for 24 hours. The mass ratio between carbon fiber, cobalt nitrate hexahydrate and 2-methylimidazole is 1:65:65. Finally, the carbon fiber cloth was taken out, washed with ethanol, and dried at 80°C for 2 hours to obtain a ZIF-67 / carbon fiber composite material;

[0064] 4) Put the ZIF-67 / carbon fiber composite material prepared in step 3) into the ethanol solution of 0.06mol / L thioacetamide for hydrothermal reaction, the mass ratio of ZIF-67 / carbon fiber composite material and thioacetami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com