Sapphire crystal bar processing system and method

A processing system and sapphire technology, applied in stone processing equipment, metal processing equipment, fine working devices, etc., can solve the problems of low efficiency when sapphire wafer is slotted, and achieve the effect of solving low efficiency and accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

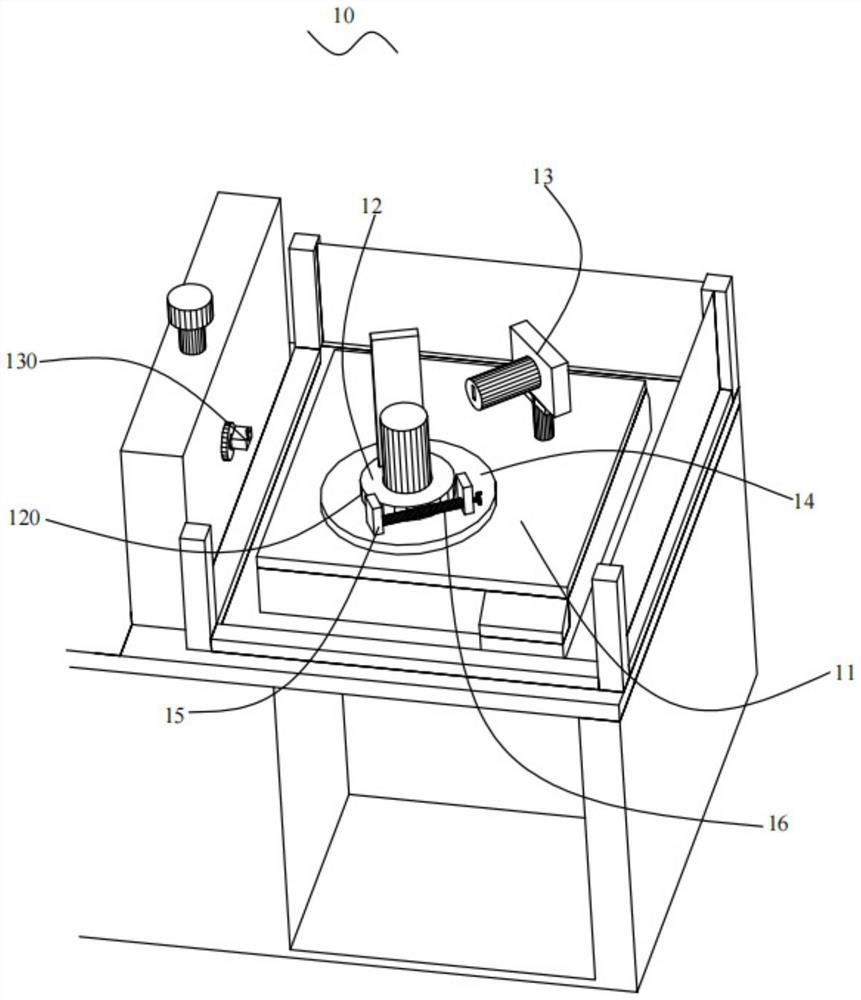

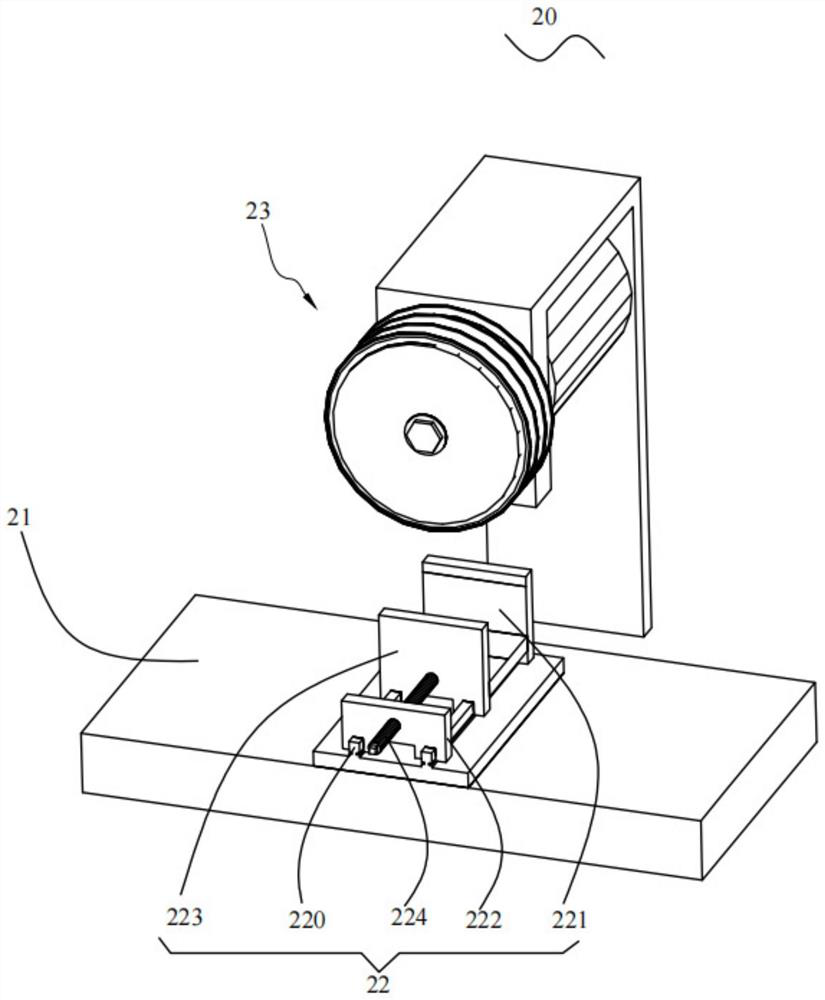

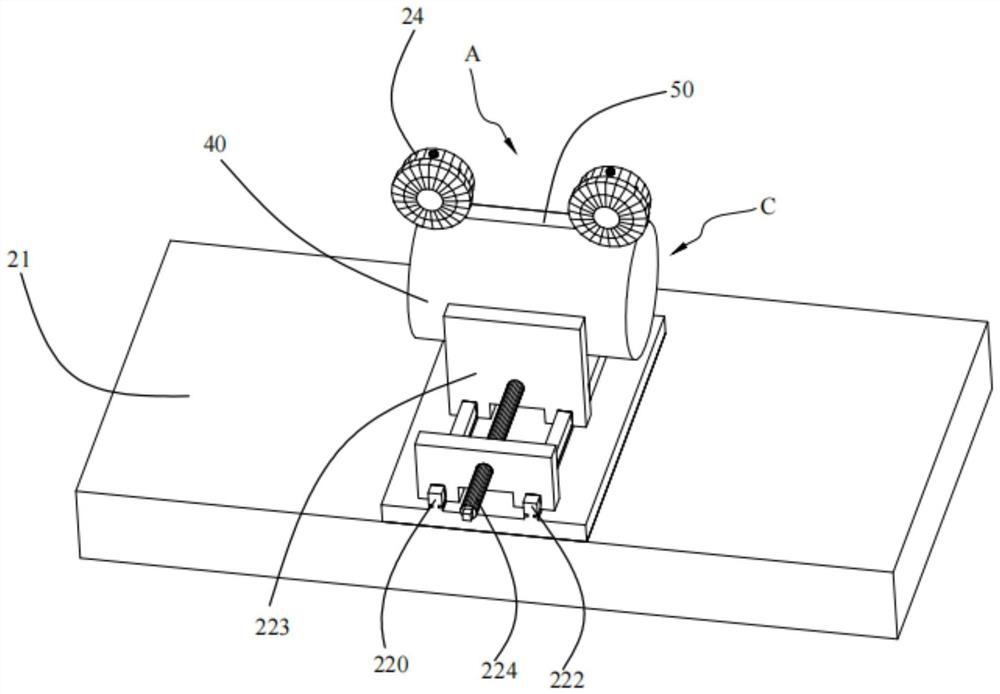

[0041] see Figure 1 to Figure 5 , shows the processing system of the sapphire crystal rod 40 in the first embodiment of the present invention, the processing system of the sapphire crystal rod 40 includes a marking mechanism 10 for cutting marks 50, a slotting mechanism 20 for slotting, and The chamfering mechanism 30 for chamfering, wherein:

[0042] The marking mechanism 10 includes a base 11, a rotating platform 12 disposed on the base 11, and an X-ray generator 13 disposed on the base 11. The rotating platform 12 is used to carry the sapphire crystal rod 40, and the rotating platform 12 is provided with a stopper. The leaning plate is used to lean against the sapphire crystal rod 40 .

[0043] During specific implementation, the sapphire crystal rod 40 is placed upright on the rotating platform 12, and a circular claw plate (not shown) is provided on the rotating platform 12 for fixing the sapphire crystal rod 40, and adjusting the position of the rotating platform 12 to...

Embodiment 2

[0060] see Figure 6 , shows the method for processing a sapphire crystal rod proposed in the second embodiment of the present invention, using the processing system for a sapphire crystal rod in the first embodiment above, and the method includes steps S10-S13.

[0061] Step S10, obtaining the A-direction of the sapphire crystal rod through the marking mechanism, and marking the A-direction of the sapphire crystal rod to obtain a cutting mark.

[0062] Step S11 , clamping the sapphire crystal ingot on the workbench by the clamping assembly, and cutting the sapphire crystal ingot along the cutting mark by using the processing abrasive.

[0063] Step S12, slicing the grooved sapphire ingot.

[0064] Step S13 , placing the slotted and sliced sapphire crystal rod on the suction cup holder, so as to chamfer the grooved and sliced sapphire crystal rod by the chamfering grinder.

[0065] In some optional embodiments of the present invention, after the wafer thickness is automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com