Manufacturing method of high-strength flywheel energy storage rotor

A technology of flywheel energy storage and manufacturing method, which is applied in the field of forging to achieve the effect of excellent radial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

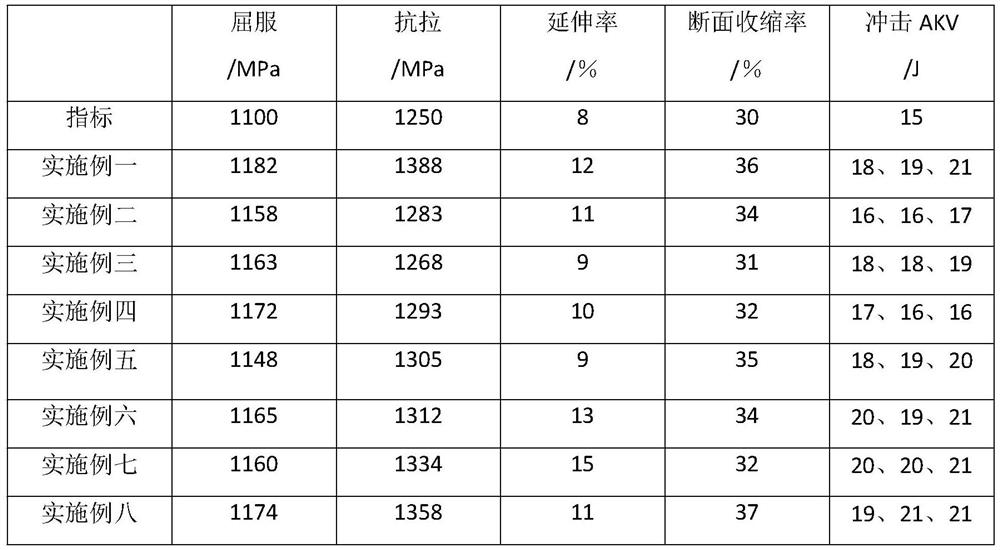

Examples

Embodiment 1

[0026] The invention provides a technical solution: a method for manufacturing a high-strength flywheel energy storage rotor, comprising the following steps:

[0027] Composition design and simulation experiments, the main components are: C, Mn, Cr, Ni, Mo, V, the element ratio is aimed at improving the hardenability, combined with the thermal simulation data, the core structure and mechanical properties of the forging are preliminarily determined;

[0028] Workpiece treatment, EF+LF+VD+IC+ESR, that is, adding electroslag remelting process on the basis of conventional smelting, casting or forging steel smelted in open hearth, converter, electric furnace, etc. into electrodes, and the molten electrodes are immersed in the slag pool of the water-cooled mold middle;

[0029] Three-way upsetting and elongating treatment, forging temperature 1247°C, upsetting and elongating in X, Y, and Z directions, upsetting ratio greater than 2, low-temperature forging in the forming stage, temp...

Embodiment 2

[0034] The invention provides a technical solution: a method for manufacturing a high-strength flywheel energy storage rotor, comprising the following steps:

[0035] Composition design and simulation experiments, the main components are: C, Mn, Cr, Ni, Mo, V, the element ratio is aimed at improving the hardenability, combined with the thermal simulation data, the core structure and mechanical properties of the forging are preliminarily determined;

[0036] Workpiece treatment, EF+LF+VD+IC+ESR, that is, adding electroslag remelting process on the basis of conventional smelting, casting or forging steel smelted in open hearth, converter, electric furnace, etc. into electrodes, and the molten electrodes are immersed in the slag pool of the water-cooled mold middle;

[0037] Three-way upsetting and elongating treatment, forging temperature 1230°C, upsetting and elongating in X, Y, and Z directions, upsetting ratio greater than 2, low-temperature forging in the forming stage, temp...

Embodiment 3

[0042] The invention provides a technical solution: a method for manufacturing a high-strength flywheel energy storage rotor, comprising the following steps:

[0043] Composition design and simulation experiments, the main components are: C, Mn, Cr, Ni, Mo, V, the element ratio is aimed at improving the hardenability, combined with the thermal simulation data, the core structure and mechanical properties of the forging are preliminarily determined;

[0044] Workpiece treatment, EF+LF+VD+IC+ESR, that is, adding electroslag remelting process on the basis of conventional smelting, casting or forging steel smelted in open hearth, converter, electric furnace, etc. into electrodes, and the molten electrodes are immersed in the slag pool of the water-cooled mold middle;

[0045] Three-way upsetting and elongating treatment, forging temperature 1235°C, upsetting and elongating in X, Y, and Z directions, upsetting ratio greater than 2, low-temperature forging in the forming stage, temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com