Growth method of large-size silicon carbide seed crystal and growth method of corresponding single crystal

A silicon carbide single crystal and silicon carbide seed technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low success rate, high process control and yield requirements, and large difference in seed crystal size. , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

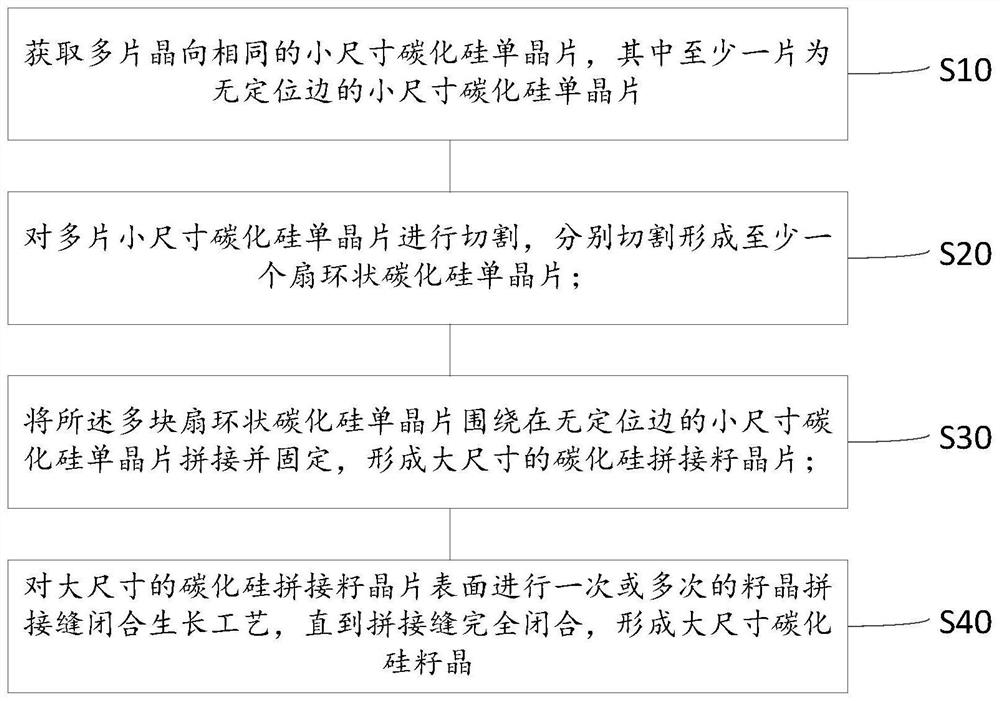

[0037] The embodiment of the present invention firstly provides a method for growing a large-sized silicon carbide seed crystal, please refer to figure 1 , including:

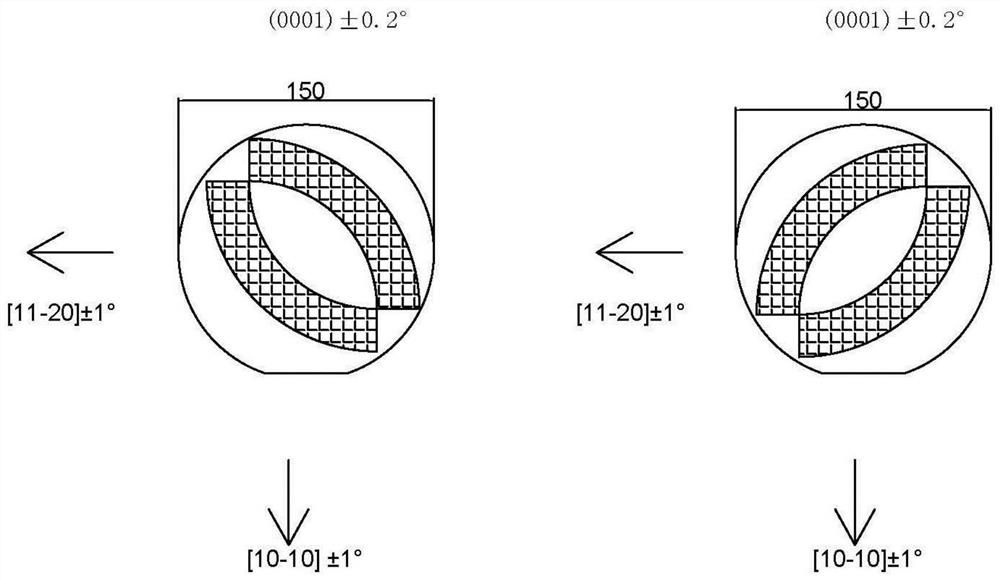

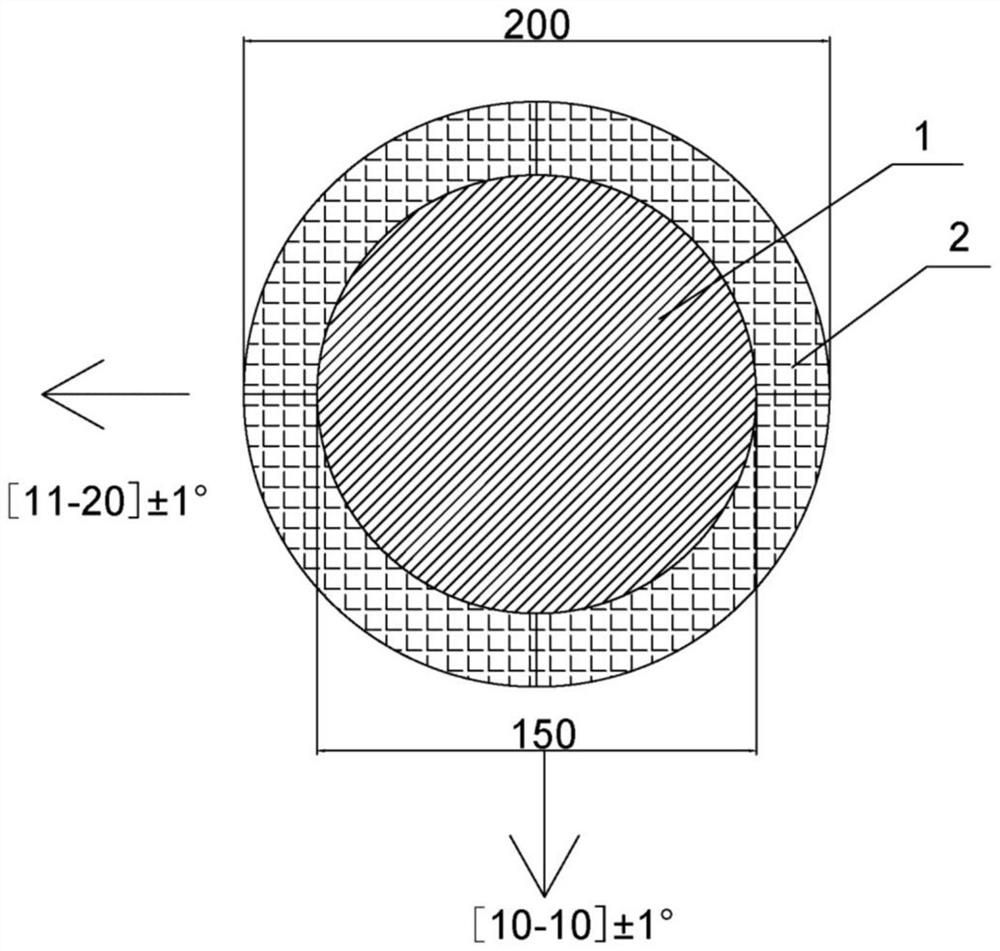

[0038] Step S10, obtaining a plurality of small-sized silicon carbide single wafers with the same crystal plane, at least one of which is a small-sized silicon carbide single wafer without positioning edges;

[0039] Step S20, cutting a plurality of small-sized silicon carbide single wafers along a specific crystal direction to form at least one sector-shaped silicon carbide single wafer, which is used to splice into a complete ring-shaped silicon carbide single wafer. Silicon single wafer, in which the inner diameter of the fan-shaped silicon carbide single wafer is consistent with the outer diameter of the small-sized silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com