Medium-high temperature semiconductor thermoelectric conversion module based on thin film integrated crystal grains

A thermoelectric conversion and semiconductor technology, which is applied in the direction of thermoelectric devices that only use the Peltier or Seebeck effect, and the manufacture/processing of thermoelectric devices, can solve problems such as component deformation and stress, unusability, etc., to reduce defects and reduce loss , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

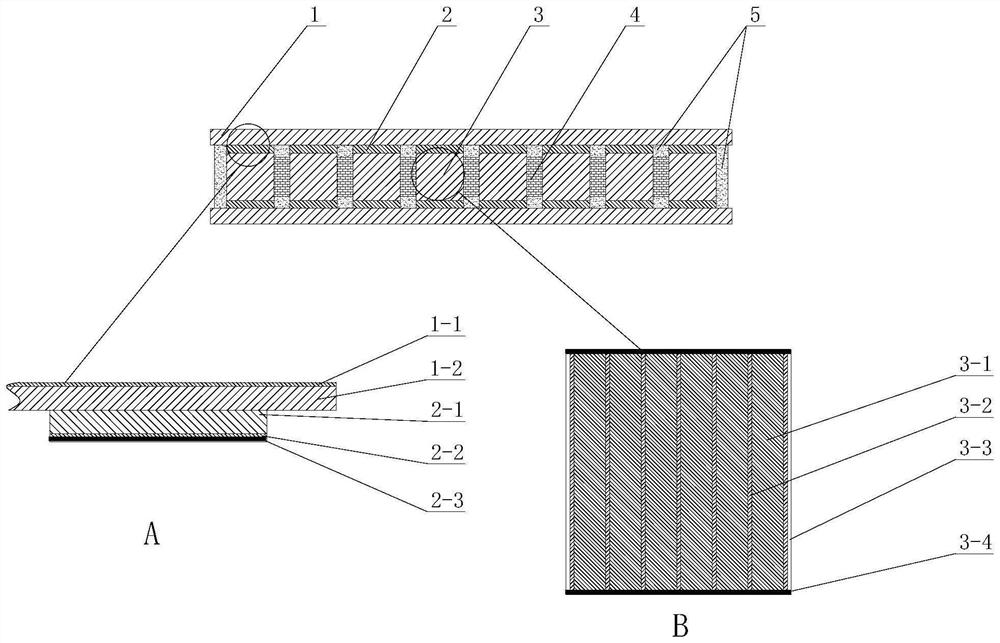

[0030] Please refer to figure 1 , this embodiment 1 is mainly composed of a heat-conducting substrate 1, a flow deflector 2, a thin-film integrated die 3, a die positioner 4, and a thermal insulation filling medium 5, etc.

[0031] Wherein the material of the outer elastic heat conduction layer 1-1 on the outside of the heat conduction substrate 1 is graphene or carbon nanotubes, preferably with a thickness of 10 microns; the material of the inner ceramic substrate 1-2 is aluminum nitride ceramics, alumina ceramics or silicon nitride ceramics , preferably aluminum nitride ceramics, the thickness is preferably 300 microns, and the external dimensions are preferably 60×60 mm;

[0032] The flow guide sheet 2 is located inside the heat conduction substrate 1, and consists of a metal substrate 2-1, an internal elastic heat conduction (flow) layer 2-2 and a metal deposition layer A2-3 from outside to inside. Wherein the metal substrate 2-1 material is copper, stainless steel, iron,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com