External skin preparation containing povidone iodine and used for treating psoriasis

A technology of povidone-iodine and psoriasis, which is applied in the field of medicine, can solve the problems of undetected psoriasis, achieve the effect of reducing psoriatic skin and nail damage, reducing skin plaques and scales, and reducing reinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

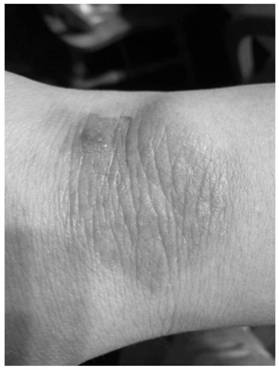

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of samples containing povidone-iodine and polyvinyl butyral and detection of film-forming time

[0029] Sample formulation (Table 1)

[0030] Table 1: Sample formulations containing povidone-iodine and different concentrations of polyvinyl butyral

[0031] sample Povidone iodine polyvinyl butyral castor oil Absolute ethanol sample 1 5g 6g 2g 87g sample 2 5g 8g 2g 85g sample 3 5g 10g 2g 83g

[0032] Sample configuration

[0033] Accurately weigh the prescribed amount of anhydrous ethanol in the container, stir at room temperature, respectively accurately weigh the prescribed amount of polyvinyl butyral, slowly add it to each container, continue to stir until it is completely dissolved, and then accurately weigh Take the povidone-iodine of the prescribed amount, slowly add it to each container, and continue to stir until it is completely dissolved. Finally, accurately weigh the castor oil of the pre...

Embodiment 2

[0039] Example 2: Determination of Film Ductility of Sample 2 in Example 1

[0040] Film-making method: cut the self-adhesive paper containing silicone oil layer with an area of 25mm*150mm and place it in a shallow groove mold of 25mm*150mm, then weigh about 1.2g of sample 2, add it dropwise and spread it on the self-adhesive On the paper, dry it with hot air from a hair dryer for about 3 minutes, and slowly tear off the film.

[0041] Testing equipment: tensile testing machine, cutting tools, stopwatch.

[0042] Detection method: Cut out a representative film with a width of (25.0±0.5)mm from the test material, let it relax for at least 300s after removing the material, and make two parallel films with a distance of (100.0±10)mm on the sample Mark, and make the two distances to the two ends equidistant, clamp the sample beyond the mark in the two grips of the tensile testing machine, and elongate the sample by 20% at a tensile speed of (300±10) mm / min. Record the maximum lo...

Embodiment 3

[0047] Embodiment 3: Determination of water vapor transmission rate of sample 2 in embodiment 1.

[0048] Film-making method: Cut the self-adhesive paper containing the silicone oil layer with an area of 5*5cm and place it in a shallow groove mold of 5*5cm, then weigh about 1.2g of sample 2, add it dropwise and spread it on the self-adhesive On the paper, dry it with hot air from a hair dryer for about 3 minutes, and slowly tear off the film.

[0049] Testing equipment: five clean drying cylinders (made of corrosion-resistant materials, with a flange at each end, can only hold 20ml of deionized water, electronic balance, hygrometer, drying box, surgical blade.

[0050] Detection method: use the flange of the splint as a template, cut off the sample of the material to be tested, add enough water at room temperature, make the air gap between the liquid surface and the placed sample be (5±1)mm, place the circle Cover the flange of the test container with the shaped sample accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com