Preparation method and application of polyhydroxyalkanoate

A technology of polyhydroxyalkanoate and bacterial strains, which is applied in the field of preparation of polyhydroxyalkanoate, can solve the problems of high COD and BOD, and low conversion rate of polyhydroxyalkanoate, so as to reduce the amount of use and facilitate industrialization The effect of simple realization and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

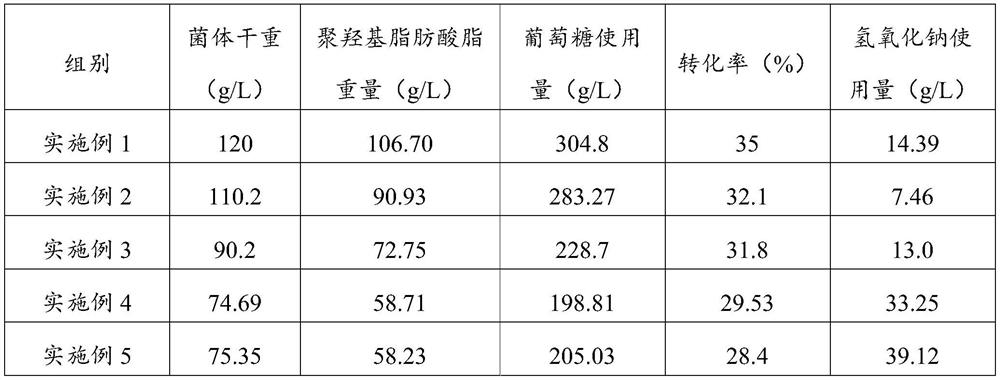

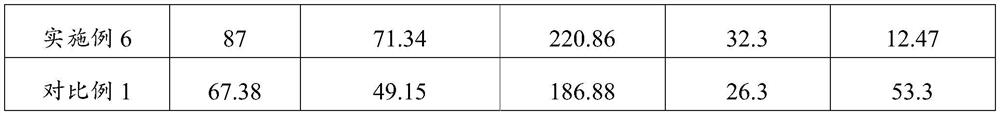

Embodiment 1

[0034] This example provides a method for preparing polyhydroxyalkanoate, which is obtained by inoculating Halomonas species into a fermentation medium for fermentation. The halomonas species is obtained by activating the halomonas and culturing seeds. The Halomonas was obtained by applying the lake water of Aiding Lake in Qinghai to the separation and purification medium, and culturing it statically at 33° C. for 24 hours.

[0035] The halomonas species is obtained after seed culture is carried out through plate culture medium activation, shake flask seed culture medium and shake flask fermentation culture medium in sequence. The plate medium includes 0.5% yeast powder, 1% peptone, 50% sodium chloride, and the pH value is 8.2; the shake flask seed medium includes 0.5% yeast powder, 1% peptone, 50% sodium chloride, the pH value is 8.2; the shake flask fermentation medium includes 0.1% yeast powder, 3% glucose, 50% sodium chloride, and the pH value is 9.0.

[0036] The prepar...

Embodiment 2

[0046] This example provides a method for preparing polyhydroxyalkanoate, which is obtained by inoculating Halomonas species into a fermentation medium for fermentation. The halomonas species is obtained by activating the halomonas and culturing seeds. The Halomonas was obtained by applying the lake water of Aiding Lake in Qinghai to the separation and purification medium, and culturing it statically at 33° C. for 24 hours.

[0047] The halomonas species is obtained after seed culture is carried out through plate culture medium activation, shake flask seed culture medium and shake flask fermentation culture medium in sequence. The plate medium includes 0.5% yeast powder, 1% peptone, 50% sodium chloride, and the pH value is 8.2; the shake flask seed medium includes 0.5% yeast powder, 1% peptone, 50% sodium chloride, the pH value is 8.2; the shake flask fermentation medium includes 0.1% yeast powder, 3% glucose, 50% sodium chloride, and the pH value is 9.0.

[0048] The prepar...

Embodiment 3

[0059] This example provides a method for preparing polyhydroxyalkanoate, which is obtained by inoculating Halomonas species into a fermentation medium for fermentation. The halomonas species is obtained by activating the halomonas and culturing seeds. The Halomonas was obtained by applying the lake water of Aiding Lake in Qinghai to the separation and purification medium, and culturing it statically at 33° C. for 24 hours.

[0060] The halomonas species is obtained after seed culture is carried out through plate culture medium activation, shake flask seed culture medium and shake flask fermentation culture medium in sequence. The plate medium includes 0.5% yeast powder, 1% peptone, 50% sodium chloride, and the pH value is 8.2; the shake flask seed medium includes 0.5% yeast powder, 1% peptone, 50% sodium chloride, the pH value is 8.2; the shake flask fermentation medium includes 0.1% yeast powder, 3% glucose, 50% sodium chloride, and the pH value is 9.0.

[0061] The prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com