Specific nitrite fluorescence detection method based on copper nanoclusters and oxidation reaction

A technology of nitrite and copper nanoclusters, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of poor portability, complicated pretreatment, high cost, etc., and achieve rapid specific detection, high sensitivity specific detection, strong The effect of fluorescence responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

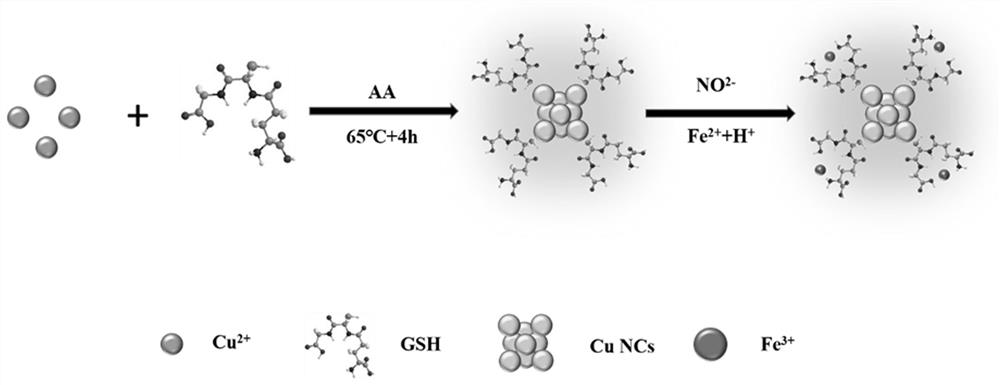

[0026] Preparation of copper nanoclusters: 125 μl CuCl 2 The solution was mixed with 20ml of 0.21 mM GSH solution under vigorous stirring for 5 min to form a copper thiol complex, at which point the mixed solution gradually became cloudy. Then, 450 μl freshly prepared 100 mM AA solution was added to the mixed solution, heated to 65 °C and continued to stir for 4 h. During this period, the solution gradually became clear, and then the solution was cooled at room temperature to obtain a Cu NCs suspension. The resulting Cu NCs suspension was stored at 4 °C for further use. The preparation and application route of Cu NCs are shown in Fig. 1.

Embodiment 2

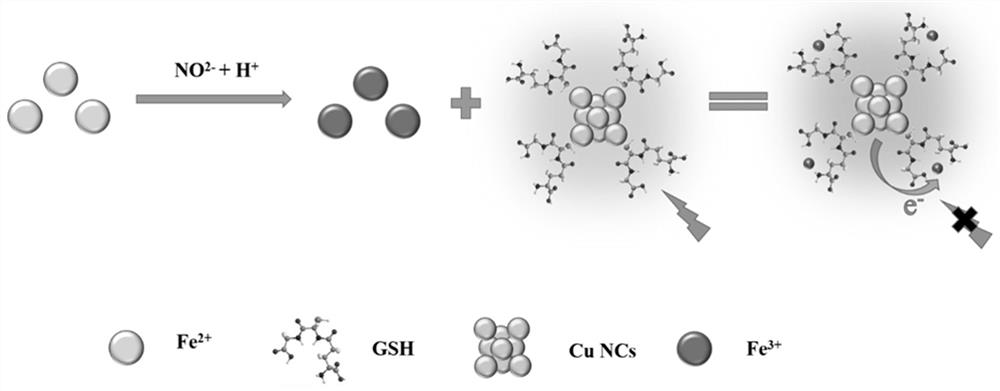

[0028] Copper nanoclusters for the detection of nitrite: taking NO 2- Mix it with an acetic acid buffer solution with a pH of 3 and place it in a centrifuge tube, then add Fe at a concentration of 150 μM to the mixture 2+ solution, vortexed to make it fully mixed, after that, 200 μl of the prepared Cu NCs was added to the above solution, and the mixture was incubated at room temperature for 30min, the detection mechanism is as follows: figure 2 shown.

Embodiment 3

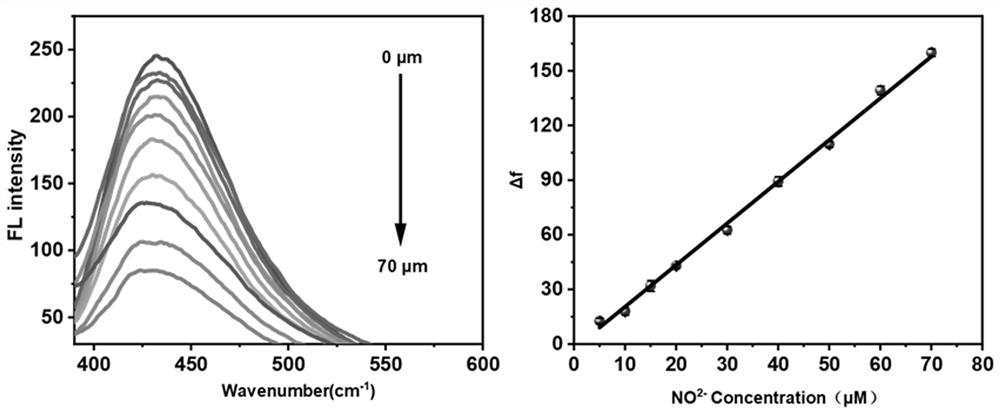

[0030] Establishment of standard curve for nitrite detection: Add solutions of different concentrations of nitrite into the specific detection system, measure the fluorescence intensity value at 432nm under the excitation of 365nm excitation light, and record the fluorescence intensity with or without nitrite after incubation Change value, construct the standard curve of the relationship between the fluorescence intensity quenching amount of nano-clusters and the concentration of nitrite in the detection method, its linear range and standard curve are as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com