Heterojunction bipolar transistor with GAA structure and preparation method thereof

A heterojunction bipolar and transistor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that the FinFET structure is difficult to meet the electrostatic control of transistors, and achieve increased injection efficiency and collector extraction The ability of carriers, reducing the transit time, and reducing the effect of base resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0049] Hereinafter, specific embodiments of the present application will be described in detail with reference to the accompanying drawings. According to these detailed descriptions, those skilled in the art can clearly understand the present application and can implement the present application. Without departing from the principles of the present application, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

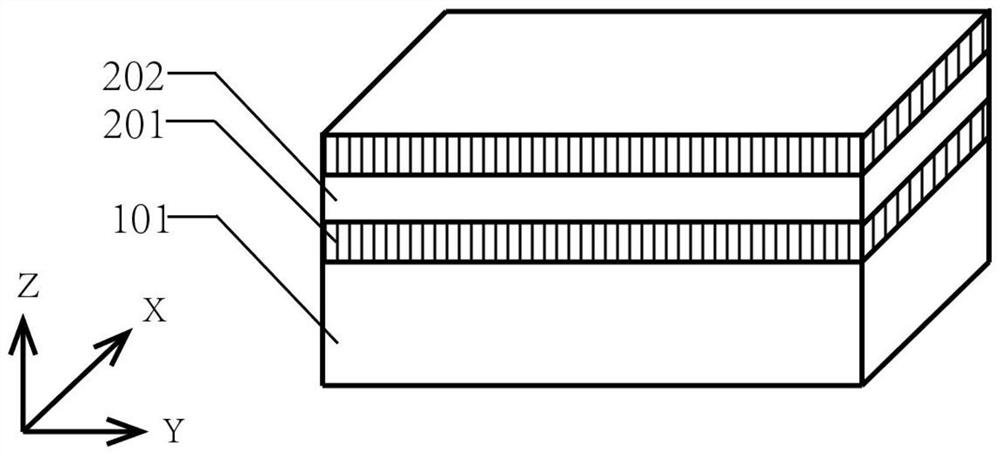

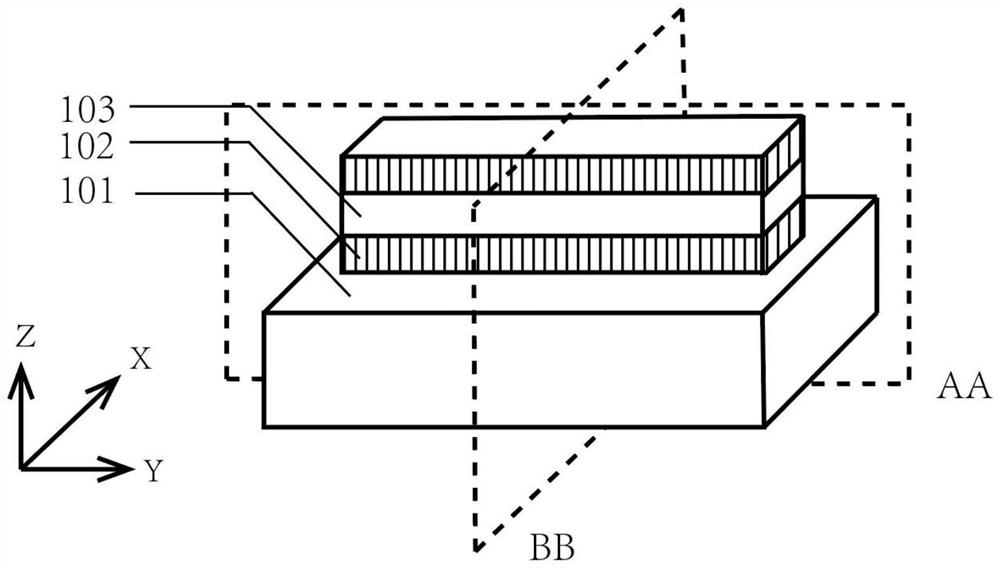

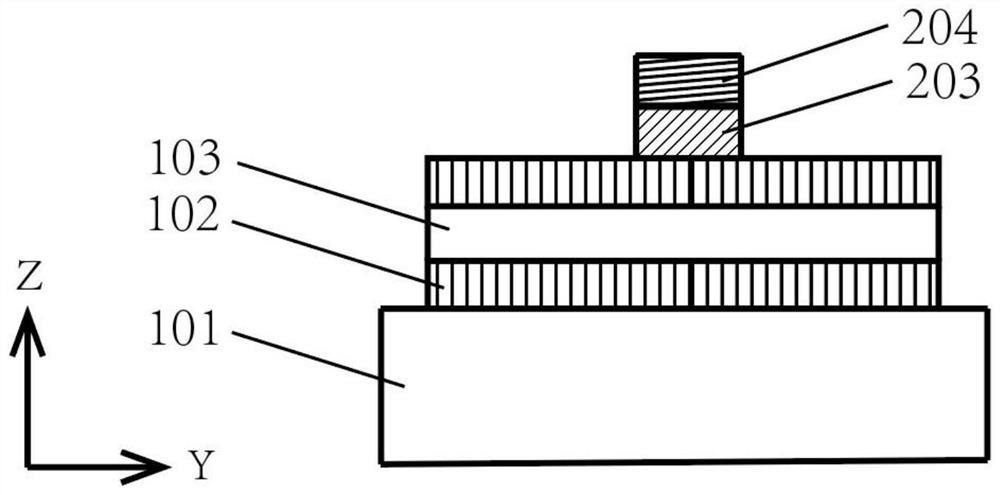

[0050] Figures 1 to 13B Shown is a schematic view of the device structure at each stage of the manufacturing process of the heterojunction bipolar transistor of the GAA structure of the embodiment of the present invention, wherein figure 1 with figure 2 is the stereogram corresponding to step 1; Figure 3A to Figure 13A is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com