Reactive dye dyeable polyurethane urea elastic yarn and manufacturing method thereof

A technology of polyurethane urea and reactive dyes, applied in the direction of one-component polyurethane rayon, one-component polyurea rayon, dyeing method, etc., can solve the problems of heat resistance decline and disappearance, and achieve enhanced heat resistance and the effect of high temperature dyeing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

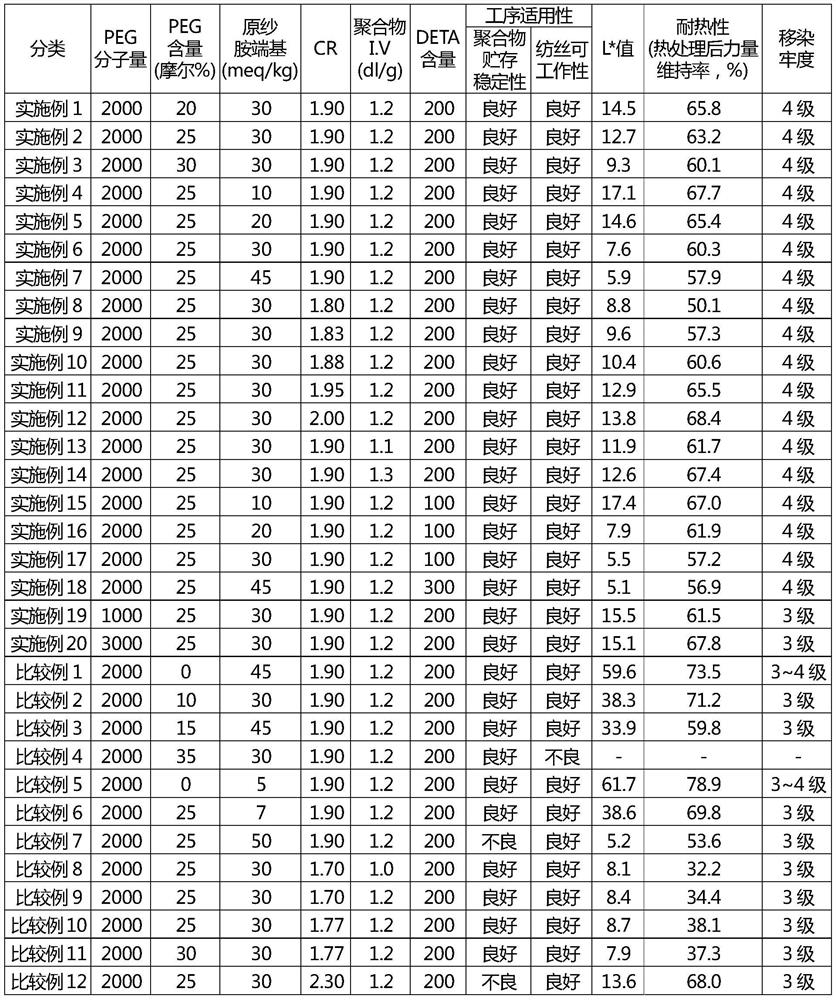

Examples

Embodiment 1

[0052] After 88.3 kg of polytetramethyl ether glycol (PTMG, molecular weight 1800) was mixed with 20.0 mol % of polyethylene glycol (molecular weight 2000), 28.5 kg of 4,4'-diphenylmethane diisocyanate was added and heated at 90 The reaction was carried out with stirring at 120°C for 120 minutes to produce a polyurethane prepolymer having isocyanate at both ends. After cooling the prepolymer to room temperature, 213.8 kg of dimethylacetamide was added as a solvent to obtain a polyurethane prepolymer solution. Next, dissolve 3.5kg of ethylenediamine as a chain extender, 0.3kg of diethylamine as a chain terminator, and 200ppm of diethylenetriamine as a viscosity stabilizer into 50kg of dimethylacetamide and heat at 10°C. Addition to the prepolymer solution at the following temperature gave a polyurethaneurea solution with an I.V of 1.2 dl / g. Further, 1.5% by weight of triethylene glycol-di-3-(3-tert-butyl-4-hydroxyphenyl) propionate as an antioxidant, 1.5% by weight as an inorg...

Embodiment 2

[0054] Polyurethane urea elastic yarn was produced in the same manner as in Example 1, except that polyethylene glycol (molecular weight: 2000) was mixed by 25 mol% during the preparation of the prepolymer of Example 1.

Embodiment 3

[0056] Polyurethane urea elastic yarns were produced in the same manner as in Example 1, except that polyethylene glycol (molecular weight: 2000) was mixed at 30 mol% during the preparation of the prepolymer of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com