Organosilicon graphene industrial coating and preparation method thereof

A technology of organosilicon and graphene, applied in the direction of coating, etc., can solve the problems of insufficient mechanical strength, limited application range, large internal stress, etc., and achieve the effect of simple production process, economical and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

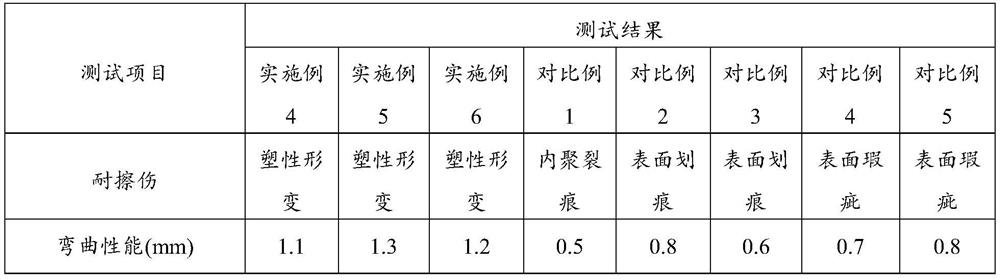

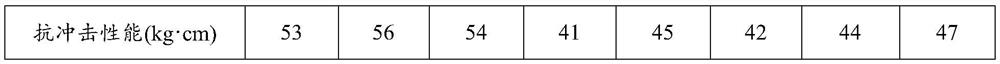

Examples

Embodiment 1

[0024] Example 1: Preparation of modified silicone resin.

[0025] Step S1. Fully mix the silicone polymer, diisocyanate, and graphene oxide, add toluene and 0.5% stannous octoate accounting for the total weight of the reaction solution, and heat up to 110° C. for 2 hours to obtain a copolymer;

[0026] Step S2. Add 4-methoxystyrene, butadiene and benzoyl peroxide to the copolymer prepared in step S1, heat up to 110° C. and react for 1 hour to obtain a modified silicone resin;

[0027] The weight ratio of the organosilicon polymer, diisocyanate, graphene oxide, 4-methoxystyrene, butadiene, and benzoyl peroxide is 1:0.01:0.2:0.1:0.1:0.001.

Embodiment 2

[0028] Example 2: Preparation of modified silicone resin.

[0029] Step S1. Fully mix the silicone polymer, diisocyanate, and graphene oxide, add ethyl acetate and dibutyltin dilaurate accounting for 1% of the total weight of the reaction solution, heat up to 70° C. and react for 2 hours to obtain a copolymer;

[0030] Step S2. Add 4-methoxystyrene, butadiene and azobisisobutyronitrile to the copolymer prepared in step S1, heat up to 70° C. and react for 1 hour to obtain a modified silicone resin;

[0031] The weight ratio of the organosilicon polymer, diisocyanate, graphene oxide, 4-methoxystyrene, butadiene and azobisisobutyronitrile is 1:0.02:0.25:0.2:0.2:0.002.

Embodiment 3

[0032] Example 3: Preparation of modified silicone resin.

[0033] Step S1. Fully mix the silicone polymer, diisocyanate, and graphene oxide, add toluene and dibutyltin dilaurate accounting for 2% of the total weight of the reaction solution, and heat up to 110° C. for 2 hours to obtain a copolymer;

[0034] Step S2. Add 4-methoxystyrene, butadiene and benzoyl peroxide to the copolymer prepared in step S1, heat up to 110° C. and react for 1 hour to obtain a modified silicone resin;

[0035] The weight ratio of the organosilicon polymer, diisocyanate, graphene oxide, 4-methoxystyrene, butadiene, and benzoyl peroxide is 1:0.03:0.3:0.3:0.3:0.003.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com