One-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, one-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor weather resistance and water resistance, low bonding strength, easy foaming of the coating film, etc., to reduce foaming The effect of drumming, high bonding strength, and excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] A second aspect of the embodiments of the present application provides a method for preparing a one-component polyurethane waterproof coating, comprising:

[0074] The first slurry is obtained by mixing the organosilicon double-ended diol, the organosilicon single-ended diol and the filler;

[0075] adding an additive whose main raw material is diisocyanate to the first slurry and reacting for a first preset time to obtain a polyurethane prepolymer;

[0076] A silane end-capping agent and a tackifier are added to the polyurethane prepolymer and reacted for a second preset time to obtain a one-component polyurethane waterproof coating.

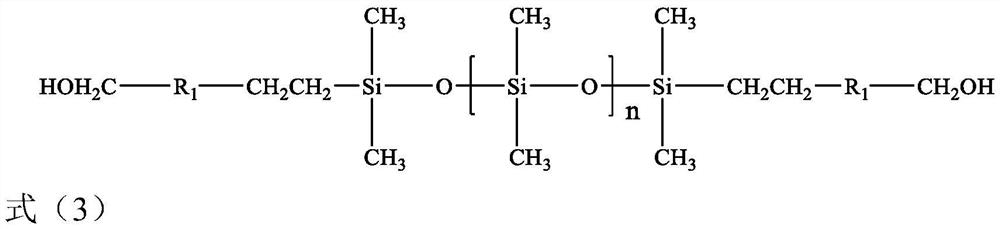

[0077] In some embodiments, the molecular weight of the organosilicon double-ended diol in the above preparation method can be selected as 1000-4000, and its molecular structure is shown in the following formula (3):

[0078]

[0079] In formula (3), R1 is an alkyl group; preferably, n is 8 to 50; more preferably, the organosilicon d...

Embodiment 1

[0104] A one-component polyurethane waterproof coating, the proportions of raw materials are as follows: tech-2120, 26 parts by weight; tech-2176, 12 parts by weight; diisononyl phthalate, 6 parts by weight; talc, 26 parts by weight ; Fumed silica, 10 parts by weight; IPDI (isophorone diisocyanate), 6 parts by weight; HDI trimer (hexamethylene diisocyanate trimer), 2 parts by weight; Neopentyl glycol, 1.2 parts by weight; γ-isocyanatopropyltriethoxysilane, 16 parts by weight; tackifier, 2 parts by weight; stannous octoate, 0.2 parts by weight; propylene glycol methyl ether acetate, 8 parts by weight.

Embodiment 2

[0106]A one-component polyurethane waterproof coating, the proportions of raw materials are as follows: tech-2120, 23 parts by weight; tech-2176, 14 parts by weight; diisononyl phthalate, 6 parts by weight; talc, 25 parts by weight ; Fumed silica, 12 parts by weight; IPDI (isophorone diisocyanate), 6 parts by weight; HDI trimer (hexamethylene diisocyanate trimer), 2.5 parts by weight; Neopentyl glycol, 1.2 parts by weight; γ-isocyanatopropyltriethoxysilane, 16 parts by weight; tackifier, 2 parts by weight; stannous octoate, 0.2 parts by weight; propylene glycol methyl ether acetate, 8 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com