Method for producing fen-flavor liquor with assistance of bamboo fibers

A fragrant-flavor liquor and bamboo fiber technology, which is applied in the field of winemaking to achieve the effects of sweetness and softness at the entrance, reducing the use of rice husks, and reducing the content of furfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

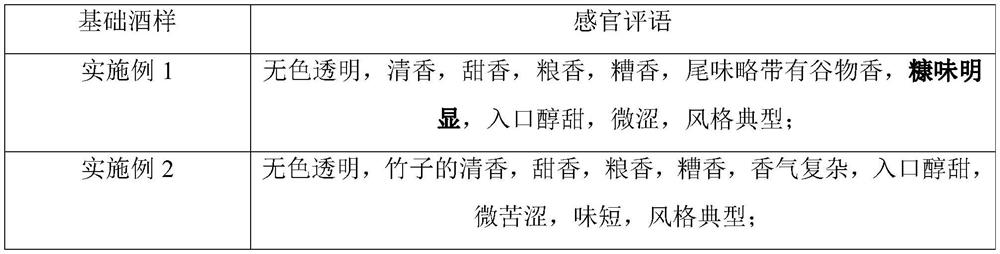

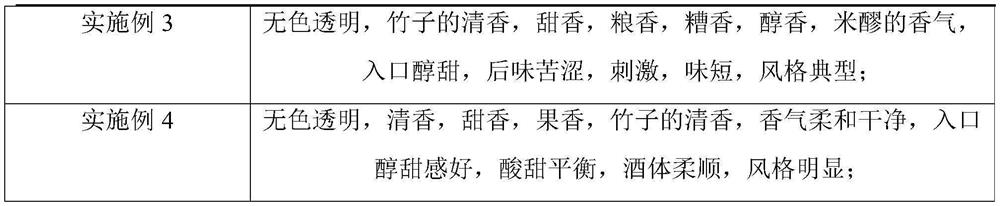

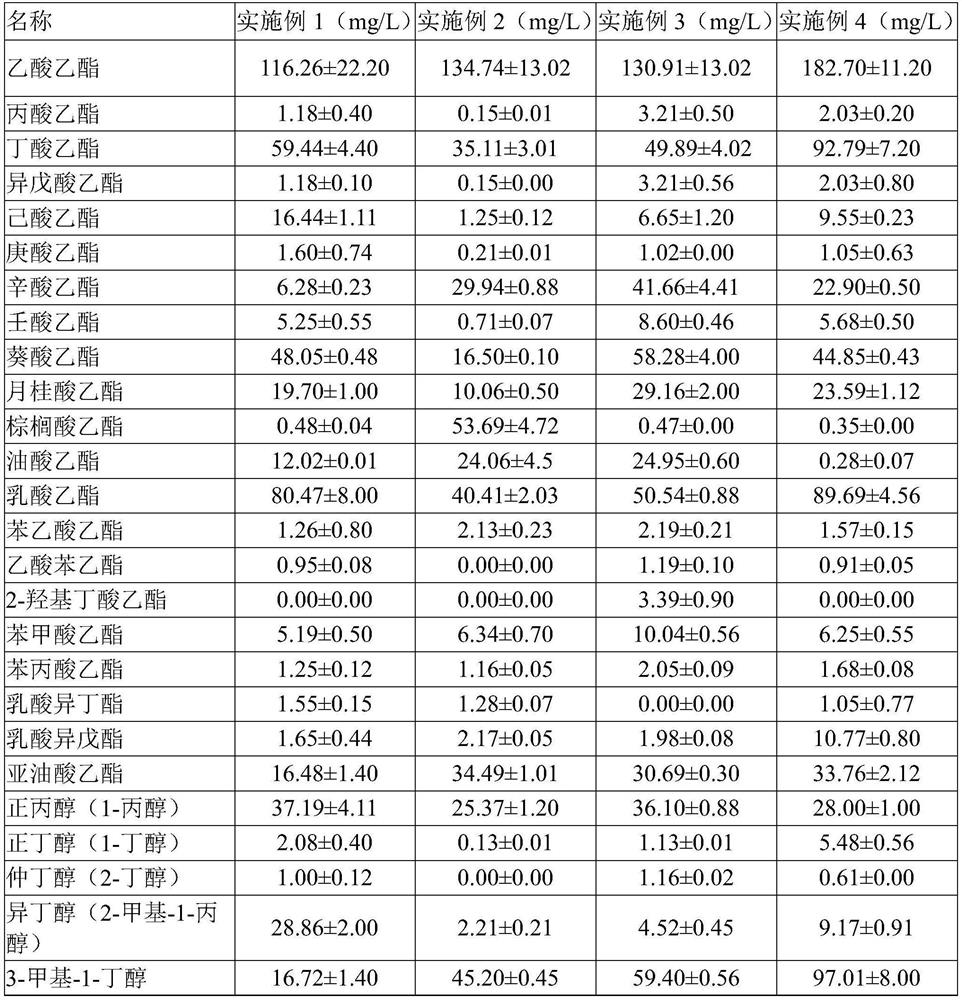

Embodiment 1

[0051] Crush sorghum into 4-6 pieces, of which 30% are fine powder that can pass through a 1.2mm sieve, and the whole sorghum must not exceed 0.3%. The crushing degree of Daqu is as large as peas and as small as mung beans, and can pass through 1.2mm. The fine powder of the sieve accounts for 70%. Get 100kg of crushed sorghum and add 55kg of water at a temperature of 75°C to moisten it, then pile it up, and add 2kg of water as raw material. The accumulation time is 16 hours, and the pile is turned twice in the middle. Sprinkle the moistened sorghum evenly into the steamer. After the steam is on the leveling surface, pour 2kg of water on the surface of the material layer and steam for 80 minutes. After the steamed sorghum comes out of the retort, add 30kg of water immediately, mix evenly, spread it out to 24°C, and add 10kg of koji. After mixing evenly, put it into the tank for large fermentation. After 28 days of fermentation Add 15kg of rice husk to the fermented grai...

Embodiment 2

[0053] Choose the Cizhu that is free from diseases and insect pests and mildew, wash and dry, and grind it to the size of rice husk, with a particle diameter of 5mm and a length of 10mm. Crush sorghum into 4-6 pieces, of which 30% are fine powder that can pass through a 1.2mm sieve, and the whole sorghum must not exceed 0.3%. The crushing degree of Daqu is as large as peas and as small as mung beans, and can pass through 1.2mm. The fine powder of the sieve accounts for 70%. Get 100kg of crushed sorghum and add 56kg of water at a temperature of 60°C to moisten it, then pile it up, and add 2 to 3kg of water as raw material. The accumulation time is 14 hours, and the pile is turned 3 times in the middle. Sprinkle 8kg of moistened sorghum and bamboo fiber evenly into the retort. After the steam is on the uniform surface, pour 2kg of water on the surface of the material layer and steam for 80min. After the steamed sorghum comes out of the retort, add 25kg of water immediately, sp...

Embodiment 3

[0055] Select no pests, no mildew, wash and dry the bamboo, and grind it to the size of rice husk, with a particle size of 8mm and a length of 10mm. Crush sorghum into 4-6 pieces, of which 30% are fine powder that can pass through a 1.2mm sieve, and the whole sorghum must not exceed 0.3%. The crushing degree of Daqu is as large as peas and as small as mung beans, and can pass through 1.2mm. The fine powder of the sieve accounts for 70%. Take 100kg of crushed sorghum and add 62kg of water at a temperature of 85°C to moisten it, then pile it up for 4 hours, and turn the pile twice in the middle. Sprinkle the moistened sorghum evenly into the steamer. After the steam is on the leveling surface, pour 2kg of water on the surface of the material layer and steam for 80 minutes. After the steamed sorghum comes out of the retort, add 30kg of water immediately, and add 10kg of koji when it is air-dried to 24°C. After stirring evenly, it can be put into the tank for large fermentati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pulverization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com