Single-phase high-entropy alloy with micron/nano crystal grain composite structure

A high-entropy alloy and composite structure technology, applied in the field of single-phase high-entropy alloys, can solve problems such as difficulties, and achieve the effects of inhibiting grain growth, excellent wear resistance in a wide temperature range, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the single-phase high-entropy alloy with micron / nano grain composite structure comprises the following steps:

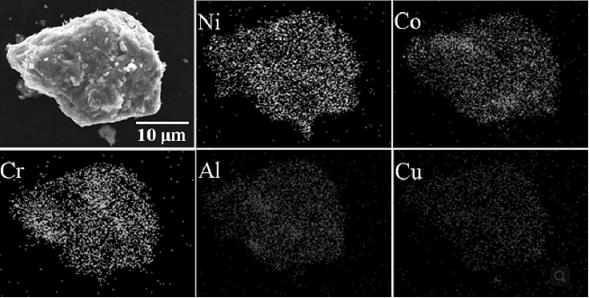

[0039] ⑴Convert Ni powder, Cr powder, Fe powder, Co powder, Al powder, Ti powder, Cu powder and B powder from the preset atomic ratio to mass ratio and weigh them into the planetary ball mill. mm tungsten carbide alloy balls are grinding balls, the ball-to-material ratio is 3.5~5.5:1, the rotation speed is 200~300 r / min, and the dry grinding fine crystallization is carried out under the condition that the protective gas is argon, and the running time is 24~ After 36 h, a dry fine-crystalline solid solution powder was obtained.

[0040] Among them: Ni powder, Cr powder, Fe powder, Co powder, Al powder, Ti powder and Cu powder are all spherical in shape, with a particle size of 20-53 μm and a purity of >99.9%. The particle size of powder B is 1~2μm, and the purity is >99.9%.

[0041] ⑵ Add 10% of the mass of absolute ethanol or ethyl ...

Embodiment 1

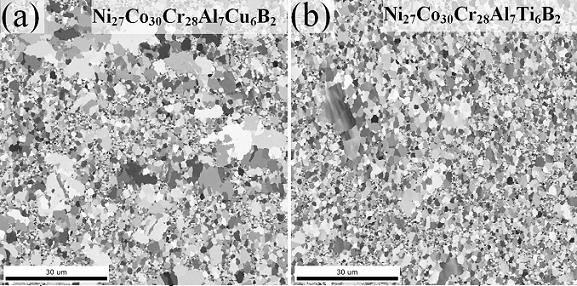

[0045] Example 1 Preparation of Ni 27 co 30 Cr 28 al 7 Cu 6 B 2 Single-phase high-entropy alloys:

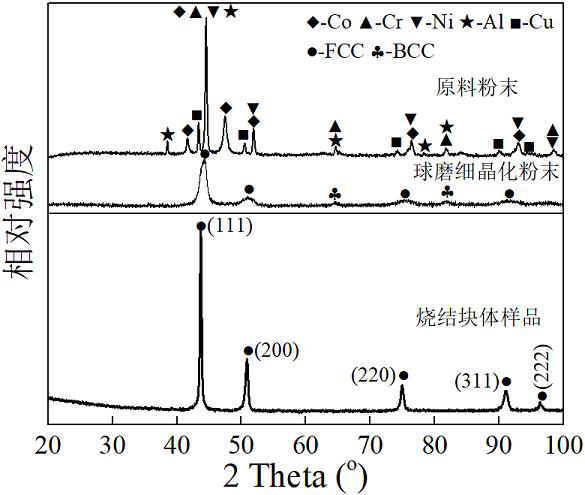

[0046] (1) Dry grinding fine crystallization process: mix Ni powder, Co powder, Cr powder, Al powder, Cu powder and B powder according to the ratio shown in Table 1, weigh them with an electronic balance, and put them into a planetary ball mill to Tungsten carbide alloy balls with a diameter of 3-15 mm are used as grinding balls, the ball-to-material ratio is 3.5:1, and the rotation speed is 250 r / min. Dry grinding and fine-graining are carried out under the condition of argon as the protective gas, and the running time is 24 hours. , to obtain dry fine-crystalline solid solution powder.

[0047] Table 1: Alloy raw material ratio (mass ratio wt.%)

[0048]

[0049] (2) Wet grinding fine crystallization process: Add 10% of its mass absolute ethanol or ethyl acetate as a process control agent to the dry fine-grained solid solution powder, put it into the planetary ball m...

Embodiment 2

[0058] Example 2 Preparation of Ni 27 co 30 Cr 28 Al 7 Ti 6 B 2 Single-phase high-entropy alloys:

[0059] (1) Dry grinding fine crystallization process: mix Ni powder, Co powder, Cr powder, Al powder, Ti powder and B powder according to the ratio shown in Table 2, weigh them with an electronic balance and put them into a planetary ball mill to The tungsten carbide alloy balls with a diameter of 3-15 mm are used as grinding balls, the ball-to-material ratio is 4:1, and the rotation speed is 300 r / min. Dry grinding and fine-graining are carried out under the condition that the protective gas is argon, and the running time is 30 h, to obtain dry fine-crystalline solid solution powder.

[0060] Table 2: Alloy raw material ratio (mass ratio wt.%)

[0061]

[0062] (2) Wet grinding fine crystallization process: Add 10% of its mass absolute ethanol or ethyl acetate as a process control agent to the dry fine-grained solid solution powder, put it into the planetary ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com