Cr-Mo-Co-V bainite high-temperature bearing steel and preparation method thereof

A cr-mo-co-v, high-temperature bearing technology, applied in the field of metallurgy, can solve problems such as reducing the life and reliability of domestic bearing steel, carbide size and distribution unevenness, and affecting the development of strategic emerging industries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] (3) The technology in the preparation method process of the high-temperature bearing steel of the present invention only involves the cycle operation of heating, heat preservation and cooling, which is simple and feasible; no chemical reagents are introduced in the whole process, and the environment will not be polluted; therefore the present invention has the advantages of Low production cost, no pollution, easy operation, significantly improve the effect of carbide uniformity and refinement;

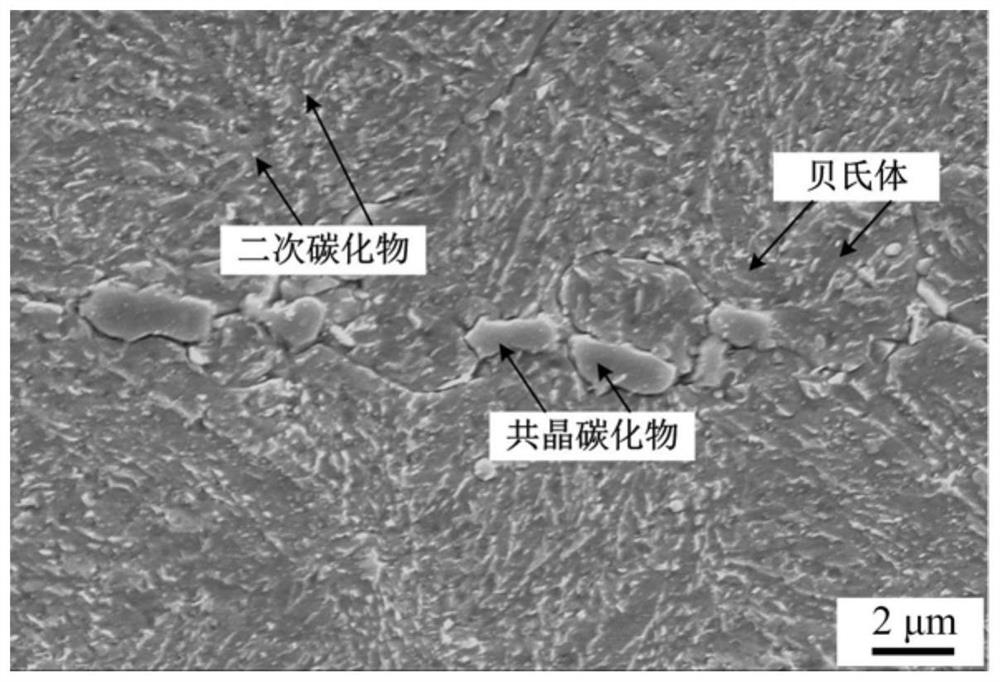

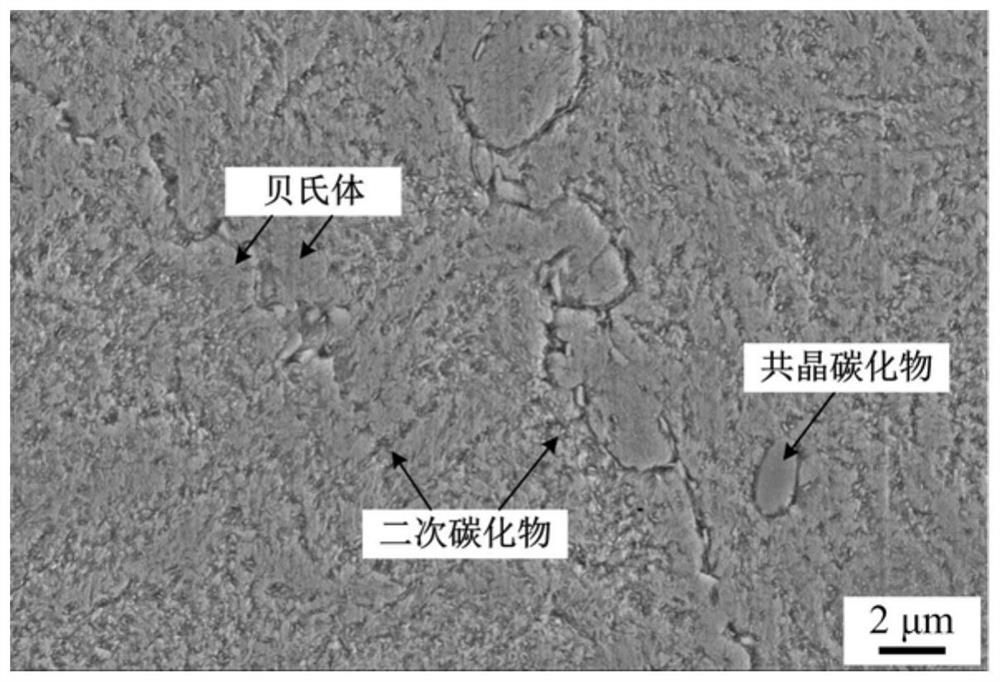

[0059] (4) By combining the first step of pre-heat treatment and the second step of pre-heat treatment, the structure of bainite was successfully obtained, and its volume percentage was controlled above 90%, and the content of retained austenite was controlled at 2 %, the volume fraction of eutectic carbides is controlled at 3% to 5%, and the volume fraction of secondary granular carbides is controlled at 0.6% to 1%, which provides a good organizational basis for bearing steel to...

Embodiment 1

[0062] A Cr-Mo-Co-V series bainitic high-temperature bearing steel, the chemical composition of which is: C: 0.7wt%, Si: 0.1wt%, Mn; 0.1wt%, P<0.005wt%, S< 0.005wt%, Mo: 4.0wt%, Cr: 3.5wt%, Co+V: 1.5wt%, and the rest are Fe and unavoidable impurity elements during smelting.

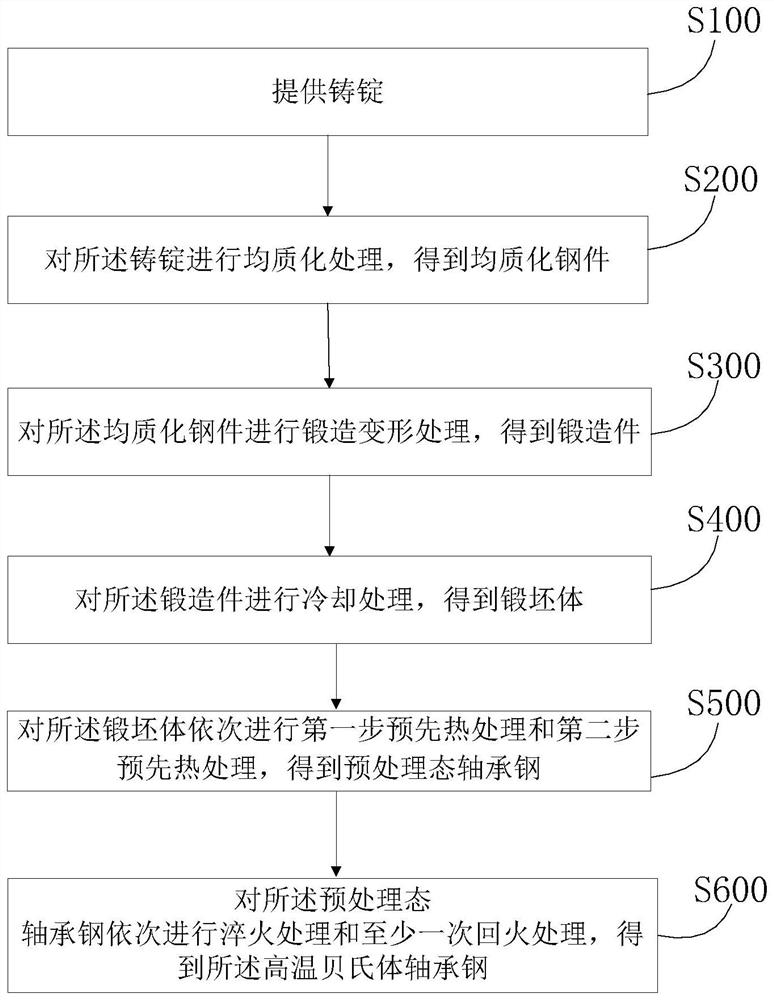

[0063] The preparation method of the above-mentioned Cr-Mo-Co-V series bainitic high-temperature bearing steel comprises the following steps:

[0064] Step 1, smelting:

[0065] High-quality molten steel is used as raw material, harmful elements are controlled to carry out triple process smelting of vacuum induction furnace, electroslag remelting and vacuum self-consumption, and the vacuum degree is controlled at 0.5×10 -2 Pa, the molten steel temperature is 1550°C, the S content is controlled to be ≤0.003wt% and the P content is ≤0.005wt%, the carbon content of the tapped steel is controlled at 0.7%, the aluminum content is controlled at 0.025wt% for the deoxidized steel, and argon gas is introduced thr...

Embodiment 2

[0081] A Cr-Mo-Co-V series bainitic high-temperature bearing steel, the chemical composition of which is: C: 0.9wt%, Si: 0.4wt%, Mn; 0.4wt%, P<0.005wt%, S< 0.005wt%, Mo: 5.0wt%, Cr: 5.5wt%, Co+V: 5.5wt%, and the rest are Fe and unavoidable impurity elements during smelting.

[0082] The preparation method of the above-mentioned Cr-Mo-Co-V series bainitic high-temperature bearing steel comprises the following steps:

[0083] Step 1, smelting:

[0084] Using high-quality molten steel as raw material, controlling harmful elements for smelting in a triple process of vacuum induction furnace, electroslag remelting and vacuum self-consumption, the vacuum degree is controlled at 0.6×10 -2 Pa, the molten steel temperature is 1600°C, the S content is controlled to be ≤0.003wt% and the P content is ≤0.005wt%, the carbon content of the tapped steel is controlled at 0.9wt%, the aluminum content is controlled at 0.035wt% for the deoxidized steel, and argon is introduced throughout the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com