V2O5 nanoflower structure-based xylene gas sensor and preparation method thereof

A gas sensor and nanoflower technology, applied in the field of sensors, can solve problems such as poor selectivity, low responsiveness, health threats, etc., and achieve the effect of good selectivity, high responsiveness, and improved gas sensitivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a V 2 o 5 The preparation method of nano flower structure, comprises the following steps:

[0037] (1) Add vanadium pentoxide and oxalic acid dihydrate into a beaker containing 20 mL of deionized water at a molar ratio of 1:3, and continuously magnetically stir at 80°C for 2 hours to obtain a blue transparent VOC 2 o 4 solution;

[0038] (2) at room temperature and under the condition of continuous magnetic stirring, to the VOC in step (1) 2 o 4 Slowly add 4.68 mL of 30% H in the solution 2 o 2 solution, and continued to stir for 20min to obtain mixed solution A;

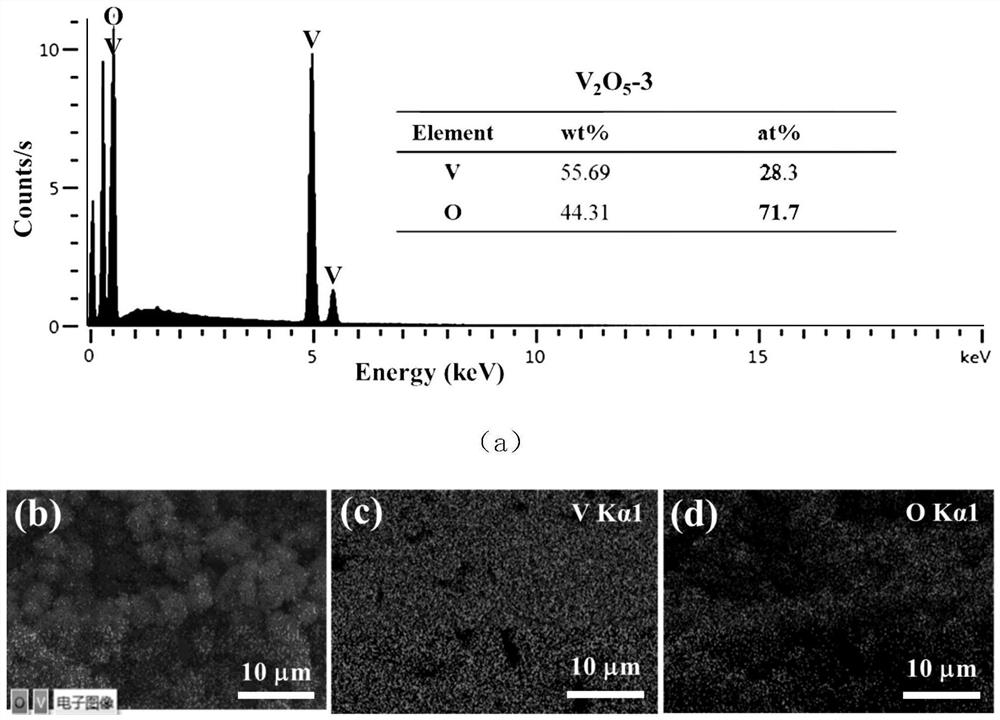

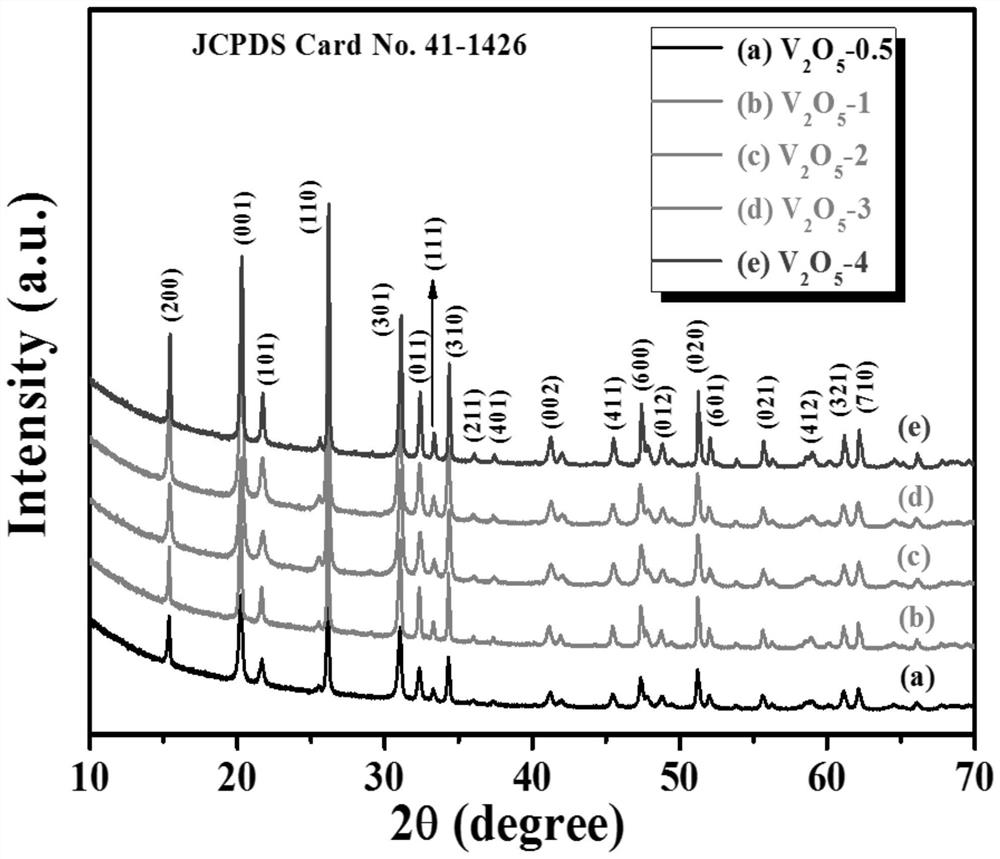

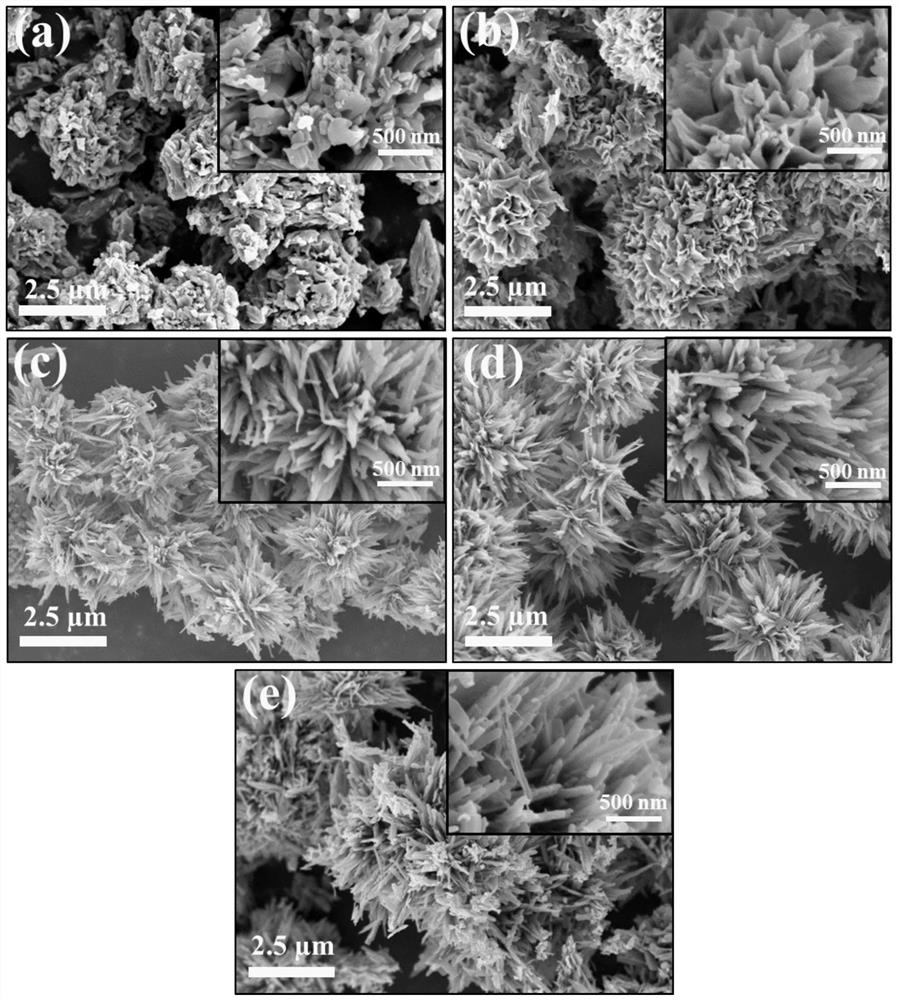

[0039] (3) Add 60 mL of ethanol solution to the mixed solution A, stir for 30 minutes to obtain the mixed solution B, divide the mixed solution B into four groups and quickly transfer them to the hydrothermal synthesis reaction kettle, and keep the four groups of mixed solutions B separately at 170°C 0.5h, 1h, 2h, 3h, 4h, and naturally cooled to room temperature, four groups of black products were obt...

Embodiment 2

[0043] A V-based 2 o 5 The xylene gas sensor with nanoflower structure consists of a ceramic tube substrate with two ring-shaped platinum electrodes arranged in parallel and separated from each other on the outer surface, sensitive materials coated on the outer surface of the ceramic tube and gold electrodes, and placed on the ceramic tube. The nickel-chromium heating coil in the tube is composed of the sensitive material V 2 o 5 Nano flower structure powder.

Embodiment 3

[0045] A V-based 2 o 5 The preparation method of the xylene gas sensor of nano flower structure comprises the following steps:

[0046] V 2 o 5 -0.5, V 2 o 5 -1, V 2 o 5 -2, V 2 o 5 -3 and V 2 o 5 -4 for the preparation of five groups of raw materials based on V 2 o 5 The xylene gas sensor with nanoflower structure is prepared as follows:

[0047] (1) Take 100g V 2 o 5 The nanoflower structure powder is mixed with 40mL ethanol solution and ground in a grinding bowl until a paste is formed;

[0048] (2) Dip a small amount of slurry with a fine brush and apply it evenly on the ceramic tube with two ring-shaped platinum electrodes arranged in parallel and separated from each other on the outer surface to form a 10-30 μm thick sensitive material film, and make the sensitive material Completely cover the ring-shaped platinum electrode, dry in the shade or bake under infrared lamps, baking under infrared lamps can speed up the drying of sensitive materials;

[0049]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Initial resistance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com