Titanium oxide nanotube-based lithium sulfide electrode and preparation method thereof

A technology of titanium oxide nanotubes and lithium sulfide, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor electronic conductivity of lithium sulfide and elemental sulfur, low battery coulombic efficiency, poor cycle life, etc., and achieve inhibition of shuttling effect, promote transport, enhance electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

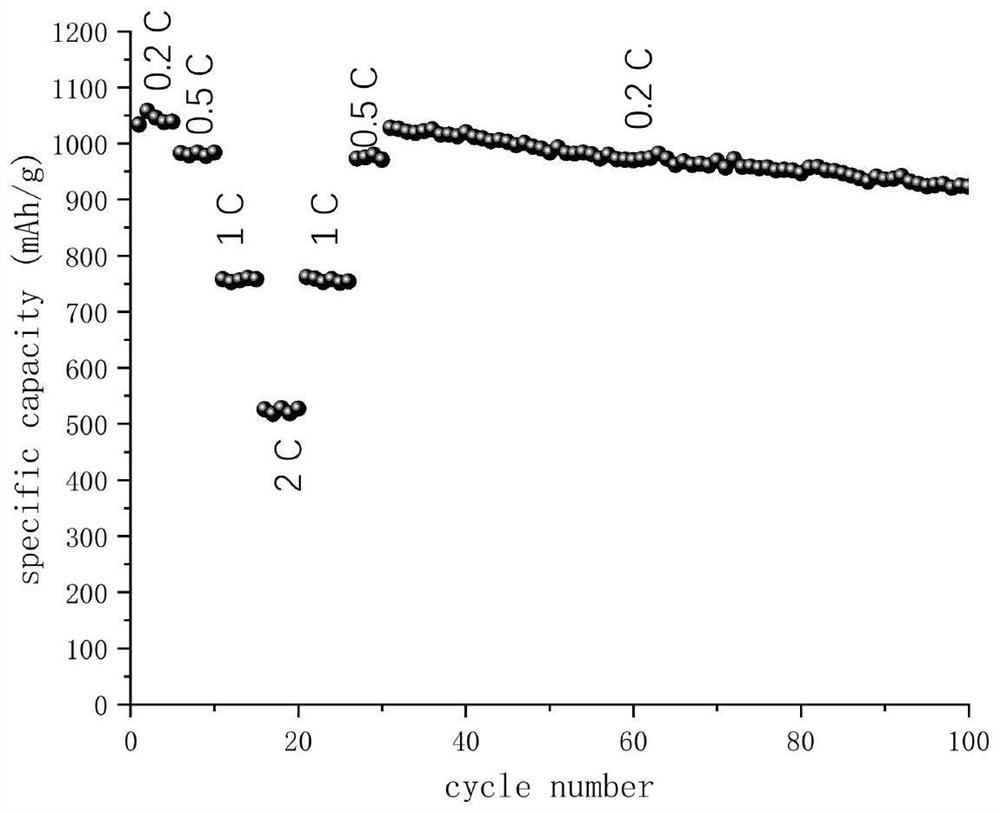

Image

Examples

Embodiment 1

[0028] A preparation method of a lithium sulfide electrode based on titanium oxide nanotubes, the specific steps are as follows:

[0029] S1, TiO nanotubes with open ends were prepared by anodic oxidation method. The titanium sheet is used as an anode, the graphite is used as a cathode, and the electrolyte is an ethylene glycol solution containing 0.1% ammonium fluoride and 0.3% water. First anodize at 50V for 8h, then switch the voltage to 100V for 1min. Washing the anodized titanium sheet in an alcohol solution makes the two-way titanium oxide nanotube array fall off from the titanium sheet substrate.

[0030] S2, the titanium oxide nanotube array was heated to 700°C at 2°C / min in the air and kept for 2h, then cooled down naturally.

[0031] S3, irradiating the titanium oxide nanotube array treated in step S2 with an ultraviolet lamp for 30 min.

[0032] S4, configure an aqueous solution of lithium sulfate and glucose, wherein the mass ratio of lithium sulfate, glucose, a...

Embodiment 2

[0035] A preparation method of a lithium sulfide electrode based on titanium oxide nanotubes, the specific steps are as follows:

[0036] S1, TiO nanotubes with open ends were prepared by anodic oxidation method. The titanium sheet is used as an anode, the graphite is used as a cathode, and the electrolyte is an ethylene glycol solution containing 0.1% ammonium fluoride and 0.3% water. First anodize at 50V for 8h, then switch the voltage to 100V for 1min. Washing the anodized titanium sheet in an alcohol solution makes the two-way titanium oxide nanotube array fall off from the titanium sheet substrate.

[0037] S2, the titania nanotube array was heated to 450°C at 2°C / min in air and kept for 2h, then cooled down naturally.

[0038] S3, irradiating the titanium oxide nanotube array treated in step S2 with an ultraviolet lamp for 10 min.

[0039] S4, configure an aqueous solution of lithium sulfate and glucose, wherein the mass ratio of lithium sulfate, glucose, and water is...

Embodiment 3

[0042] A preparation method of a lithium sulfide electrode based on titanium oxide nanotubes, the specific steps are as follows:

[0043] S1, TiO nanotubes with open ends were prepared by anodic oxidation method. The titanium sheet is used as an anode, the graphite is used as a cathode, and the electrolyte is an ethylene glycol solution containing 0.1% ammonium fluoride and 0.3% water. First anodize at 50V for 8h, then switch the voltage to 100V for 1min. Washing the anodized titanium sheet in an alcohol solution makes the two-way titanium oxide nanotube array fall off from the titanium sheet substrate.

[0044] S2, the titania nanotube array was heated to 500°C in air at 2°C / min and kept for 2h, then cooled down naturally.

[0045] S3, irradiating the titanium oxide nanotube array treated in step S2 with an ultraviolet lamp for 20 minutes.

[0046] S4, configure an aqueous solution of lithium sulfate and glucose, wherein the mass ratio of lithium sulfate, glucose, and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com