Method for modifying pea protein by using protein glutaminase

A technology of glutaminase and pea protein, which is applied in the field of protein modification, can solve the problems of poor deamidation effect, high cost, and safety issues, and achieve the effects of improved deamidation degree, low allergies, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

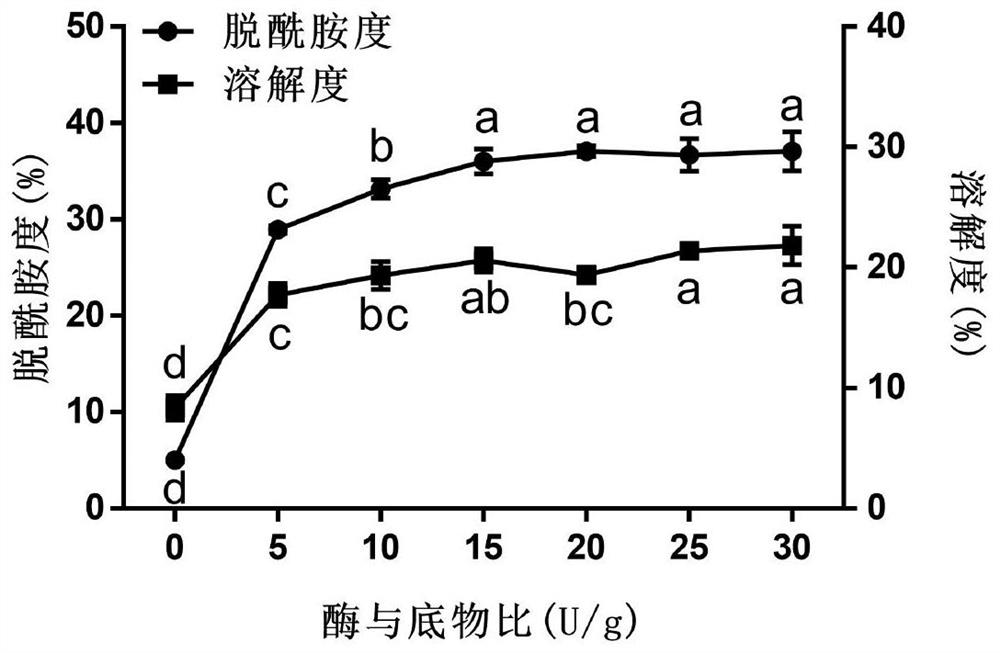

[0060] Take 0.2 g of pea protein and add it into 20 mL of pH 7.0 phosphate buffer (0.05 M) while stirring to form a protein dispersion solution with a substrate concentration of 1% (w / v). Control the ratio of protein glutaminase and pea protein substrate to 0, 5, 10, 15, 20, 25, 30U / g respectively, the reaction temperature is 50°C, the reaction time is 2h, and the deamidation degree and solubility of the reactant are measured . See the test results figure 1 .

[0061] Depend on figure 1 It can be seen that when the reaction time is 2h, the deamidation degree and solubility of pea protein increase gradually with the increase of the ratio of enzyme to substrate. When the ratio of enzyme to substrate was between 0-5U / g, the degree of deamidation and solubility increased rapidly, and then showed a trend of slow increase. When the enzyme-substrate ratio reaches 15U / g, the deamidation degree of pea protein is 36.01%, and the solubility is 20.59%. When the ratio of enzyme to sub...

Embodiment 2

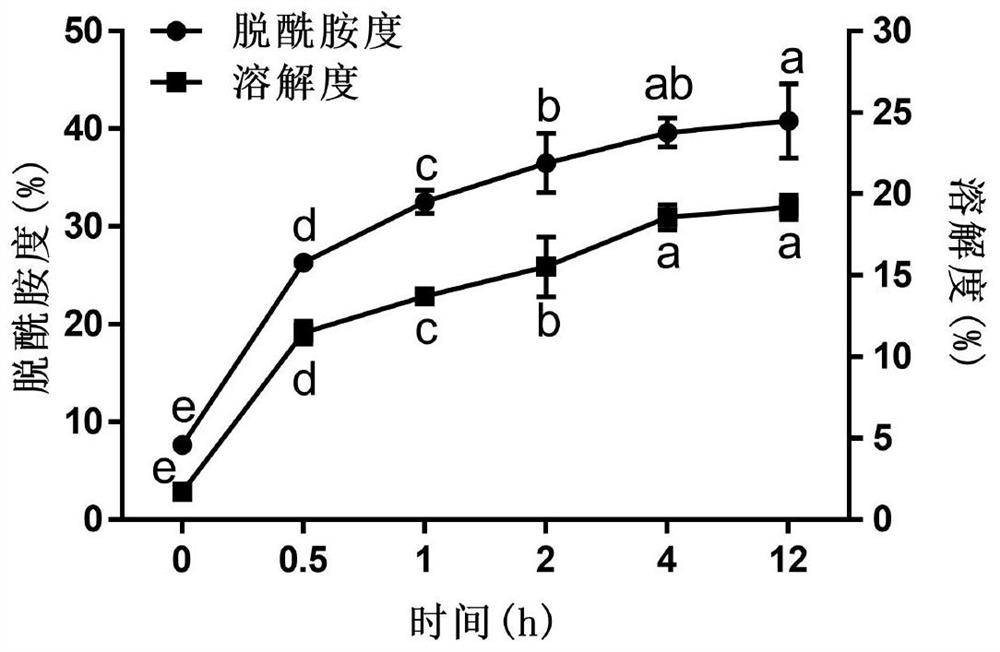

[0063] Take 0.2 g of pea protein and add it into 20 mL of pH 7.0 phosphate buffer (0.05 M) while stirring to form a protein dispersion solution with a substrate concentration of 1% (w / v). The ratio of protein glutaminase to pea protein substrate was controlled at 15U / g, the reaction temperature was 50°C, and the reaction time was 0, 0.5, 1, 2, 4, 12h, respectively, and the deamidation degree and solubility of the reactants were measured. See the test results figure 2 .

[0064] Depend on figure 2 It can be seen that when the ratio of enzyme to substrate is 15U / g, the degree of deamidation and solubility of pea protein increase gradually with the extension of reaction time. After 4 hours of reaction, the deamidation degree of pea protein reached 39.62%, and its solubility reached 18.55%, both of which were not significantly different from the results of 12 hours of reaction, indicating that the pea protein modified by PG enzyme had been completely reacted at 4 hours.

Embodiment 3

[0065] Embodiment 3 (comparative example)

[0066] Take 0.2 g of pea protein and add it into 20 mL of pH 7.0 phosphate buffer (0.05 M) while stirring to form a protein dispersion solution with a substrate concentration of 1% (w / v). The ratio of protein glutaminase to pea protein substrate is 0U / g. Shake on a shaker at 220r / min for 2h at 50°C. After shaking, the pea protein dispersion was placed in a water bath at 80° C. for 10 minutes. Finally, the pea protein dispersion was subjected to vacuum freeze-drying to obtain non-deamidated modified pea protein. The vacuum freeze-drying conditions were as follows: the temperature was -50° C., the vacuum degree was 10 Pa, and the drying time was 48 hours. The deamidation degree of undeamidated pea protein was detected to be 5.63%, and the solubility was 6.51%. The results of foamability and emulsification stability are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Emulsion stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com