Method for improving laser bending forming precision of single curved surface of fiber metal laminate

A fiber metal laminate and bending forming technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of non-plastic deformation of metal, affecting the use risk of complex curved surface forming accuracy, and reduce the cumulative rebound deformation. , Improve the accuracy of laser bending forming and suppress interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: Laser scanning forming of glass fiber reinforced aluminum alloy laminates with multiple lines side by side and equidistant single curved surface.

example 1

[0027] Example 1, uncorrected shape sample production (comparative example):

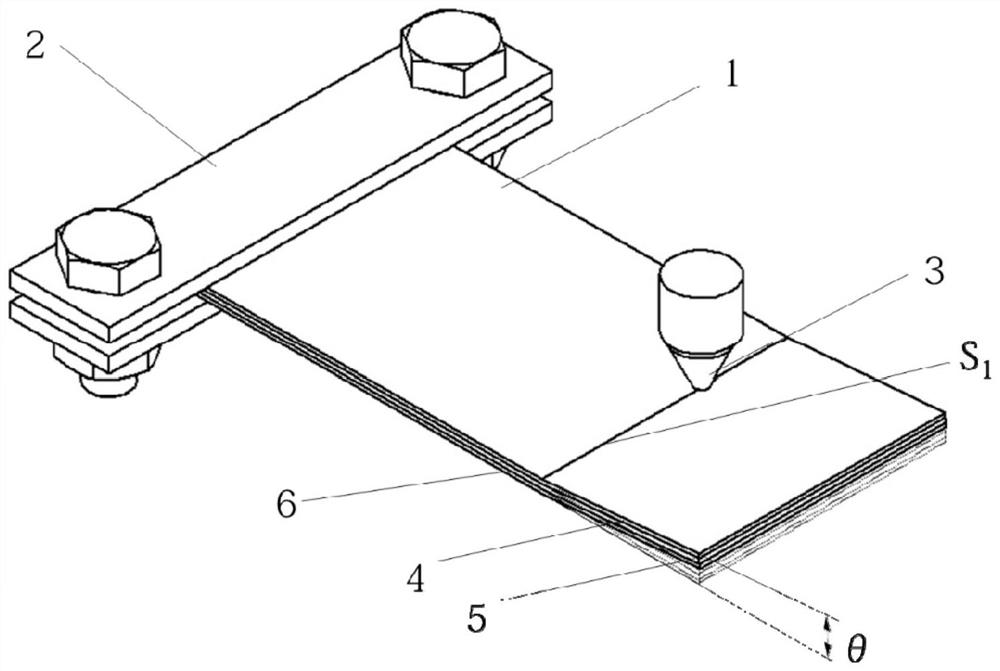

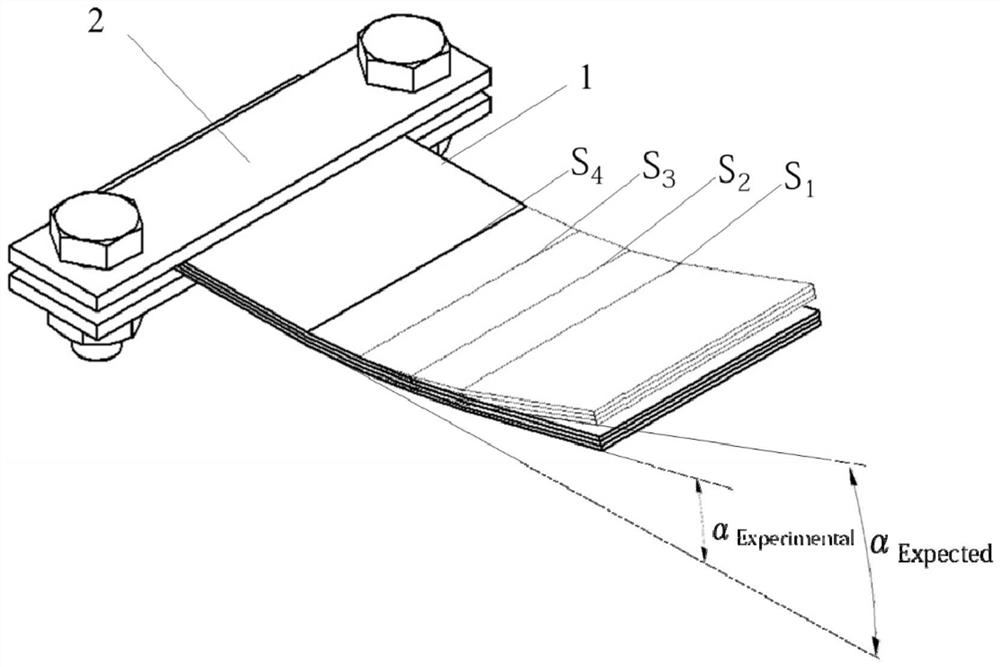

[0028] ①Fiber metal laminate 1 is made of glass fiber reinforced aluminum alloy laminate, the type is GLARE 4B-2 / 3, and the plate is processed into a rectangular sample with a thickness of 1mm, a width of 25mm and a length of 60mm by using an abrasive water jet processing platform . The scanning path is as shown in the figure, the number of scanning tracks N=4, the single-track target bending angle θ=3°, and the scanning distance d=6mm. In order to increase the light absorption rate, scan line S on the upper metal layer 1 , S 2 , S 3 , S4 The position is treated with carbon black. In order to avoid delamination of the plate, the distance between the scanning line and the edge of the plate is L 1 ≥15mm, this embodiment L 1 = 16 mm.

[0029] ② Clamp one end of the fiber metal laminate 1 with a clamp 2 and place it on the workbench of the laser processing machine. Scanning line S along the set u...

example 2

[0031] Example 2, the production of proofreading samples:

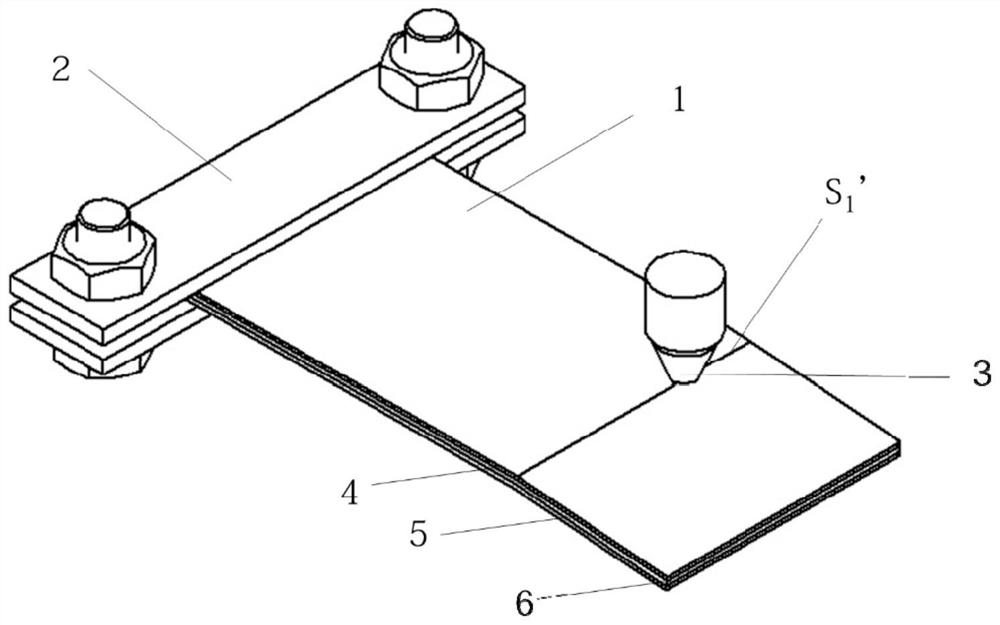

[0032] ① Fiber metal laminate 2 is made of glass fiber reinforced aluminum alloy laminate, the type is GLARE 4B-2 / 3, and the plate is processed into a rectangular sample with a thickness of 1mm, a width of 25mm and a length of 60mm by using an abrasive water jet processing platform . The scanning path on the surface of the upper metal layer is as follows: Figure 4 As shown, the number of scanning tracks N=4, the single-channel bending angle θ=3°, and the scanning pitch P=6mm. The scanning path on the surface of the lower metal layer is as follows: Figure 5 As shown, it is located directly below the scanning path on the surface of the upper metal layer, corresponding to it one by one. In order to increase the light absorption rate, scan line S on the upper metal layer 1 , S 2 , S 3 , S 4 , the lower metal layer scan line S 1 ’, S 2 ’, S 3 ’, S 4 ’ The position is treated with carbon black. To avoid delamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com