Nanocrystalline silicon carbide superhard block and preparation method thereof

A technology of silicon carbide and nanocrystals, which is applied in the field of nanocrystalline silicon carbide superhard blocks and its preparation, to achieve the effects of improving density and hardness, improving activity, and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

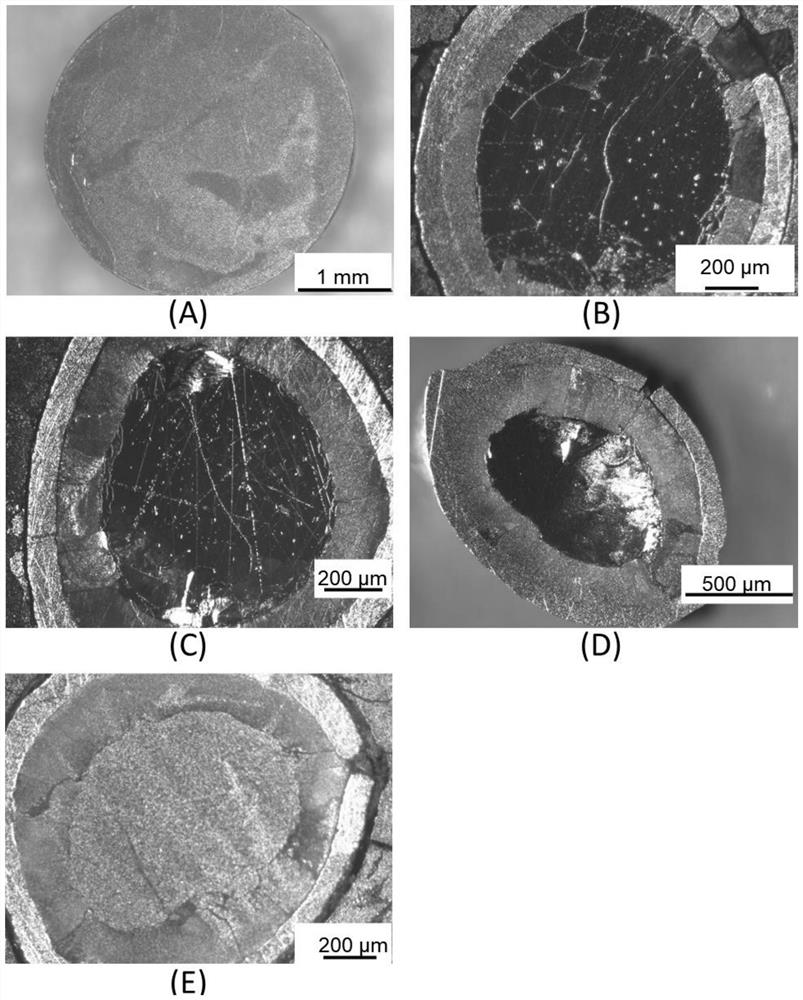

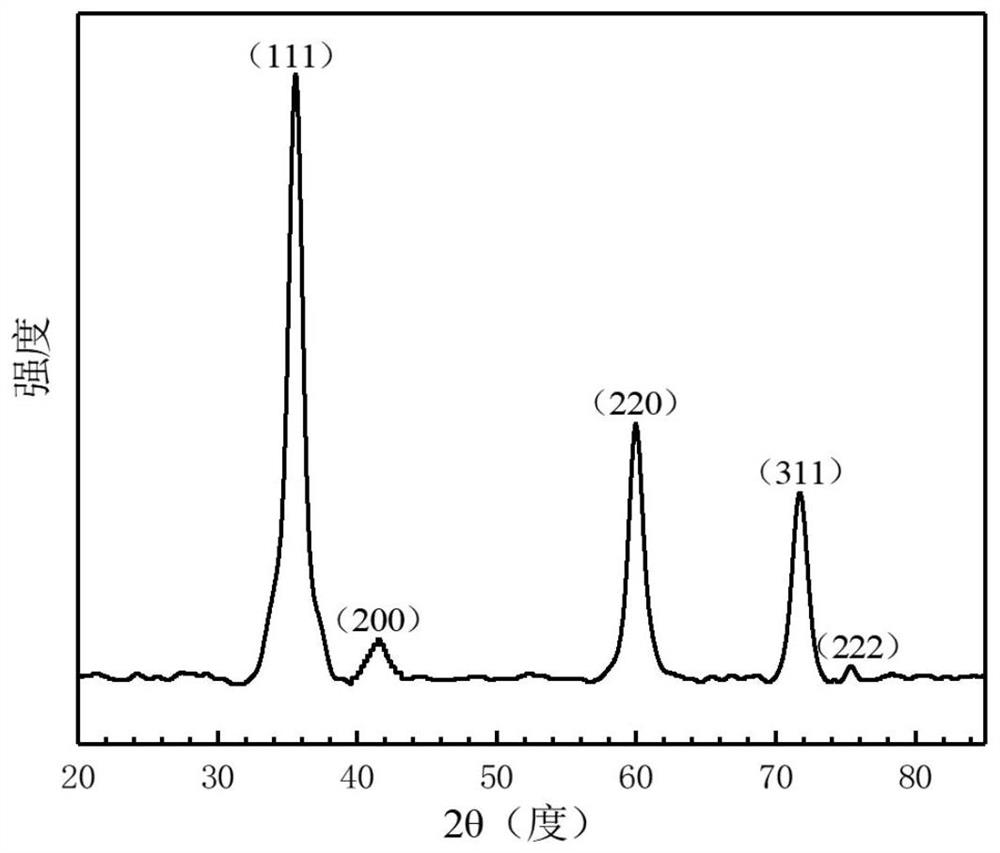

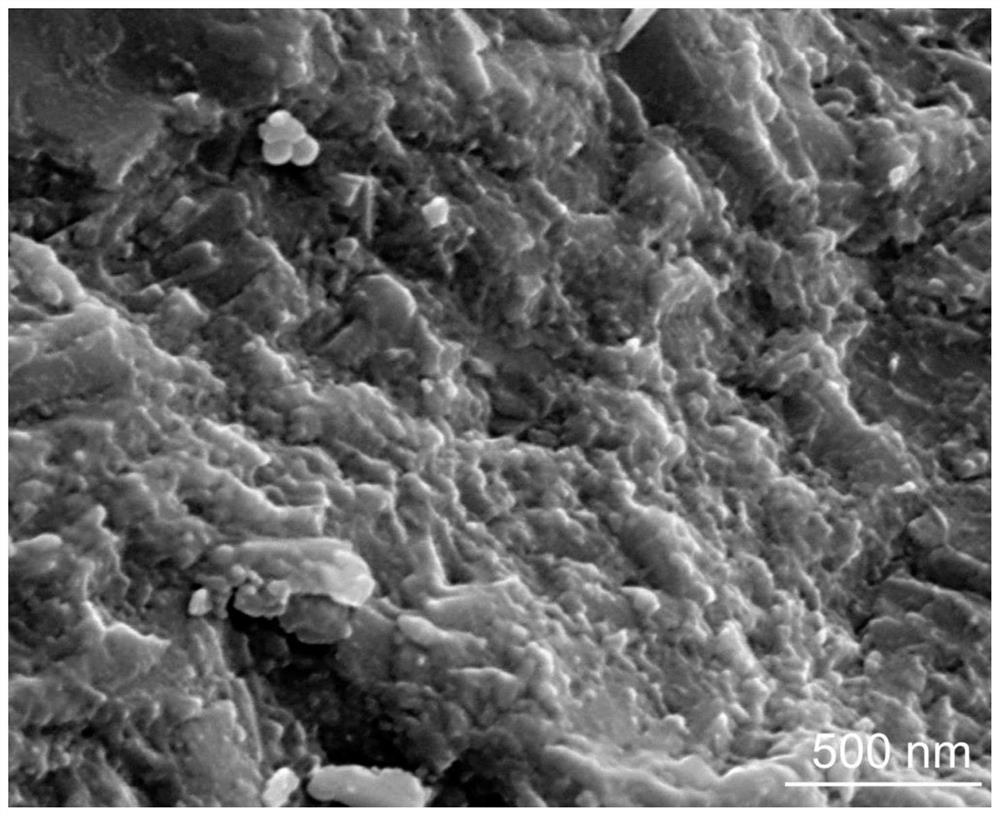

Embodiment 1

[0068] 0.3 g of silicon carbide raw material (average grain size: 5 nm) was treated with 10% hydrofluoric acid, and the pickling time was 60 min. The acid solution is diluted with deionized water, and a combination of centrifuge and ultrasonic cleaner is used in this process. The acid liquid is separated from the raw material by centrifugation, and the raw material is mixed evenly with the newly added deionized water by ultrasonic. Repeat several times until the pH is close to 7. The centrifuge speed is 4000r / min, the centrifugation time is 15min, and the ultrasonic time is 5min. The raw materials obtained by the last centrifugation were dried at a temperature of 60° C. for 18 hours.

[0069] Apply a pressure of 10MPa to the dried powder to prefabricate a cylindrical body with a diameter of 3.5mm and a height of 3mm, put it into a hexagonal boron nitride crucible, and put the assembly block into a domestic hexagonal top synthesis device , sintering under the conditions of p...

Embodiment 2

[0071] 0.3 g of silicon carbide raw material (average grain size: 30 nm) was treated with 10% hydrofluoric acid, and the pickling time was 30 min. The acid solution is diluted with deionized water, and a combination of centrifuge and ultrasonic cleaner is used in this process. The acid liquid is separated from the raw material by centrifugation, and the raw material is mixed evenly with the newly added deionized water by ultrasonic. Repeat several times until the pH is close to 7. The centrifuge speed is 11000r / min, and the centrifugation time is 20min. Ultrasonic time is 10min. Dry the raw material obtained from the last centrifugation. The drying temperature is 40°C and the drying time is 24h.

[0072] Apply 10MPa pressure to the dried powder to prefabricate a cylindrical body with a diameter of 1.2mm and a height of 2.3mm, put it into a hexagonal boron nitride crucible, put the assembled block into a T25 press, and press 15GPa, sintering at a temperature of 1500°C, and...

Embodiment 3

[0074] 0.15 g of silicon carbide raw material with an average grain size of 5 nm and 0.15 g of silicon carbide raw material with an average grain size of 70 nm were mixed. The mixed raw material was treated with 10% hydrofluoric acid. Pickling time is 45min. The acid solution is diluted with deionized water, and a combination of centrifuge and ultrasonic cleaner is used in this process. The acid liquid is separated from the raw material by centrifugation, and the raw material is mixed evenly with the newly added deionized water by ultrasonic. Repeat several times until the pH is close to 7. The rotational speed of the centrifuge is 11000r / min, and the centrifugation time is 15min. Ultrasonic time is 5min. Dry the raw material obtained from the last centrifugation. The drying temperature is 40°C, and the drying time is 24 hours.

[0075] Apply 10MPa pressure to the dried powder to prefabricate a cylindrical body with a diameter of 1.2mm and a height of 2.3mm, put it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com