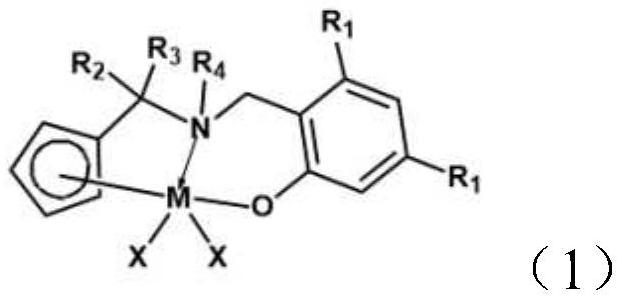

Metallocene catalyst, preparation method and application of metallocene catalyst in catalysis of olefin polymerization

A metallocene catalyst and alkali metal technology, applied in the field of olefin polymerization, can solve the problems of increased production cost, metal residues, limited application scope of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

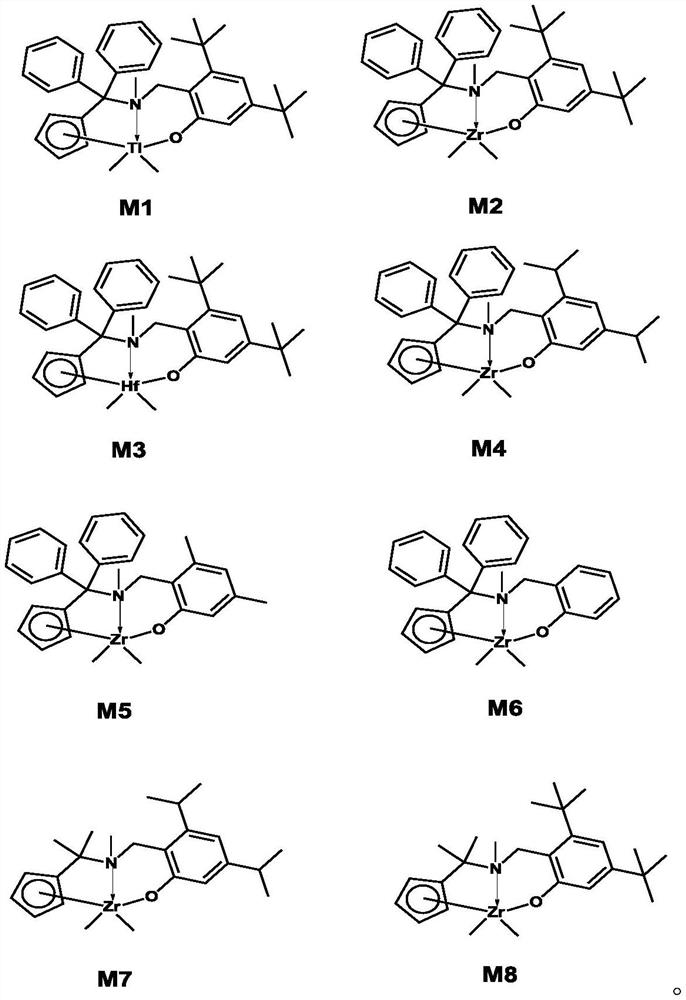

Embodiment 1

[0099] Preparation of Catalyst M1:

[0100] 1) Under nitrogen atmosphere, mix 2-aminomethyl-3,5-di-tert-butylphenol (23.5g, 100mmol) and imidazole (6.8g, 100mmol) in 45.4g tetrahydrofuran, add dimethyl tert-butyl Chlorosilane (15.1g, 100mmol), reacted at 0°C for 0.5h, removed THF under reduced pressure, added 100mL of water and ethyl acetate for extraction and separation, removed ethyl acetate under reduced pressure, column chromatography (eluent volume ratio 1 : 1 petroleum ether and ethyl acetate) to obtain intermediate A1, 34.3g, yield 98%.

[0101] 1 H NMR (400MHz, CDCl 3 ):δ8.61(s,2H,NH 2 ),6.94((dd,1H,J=6.3,11.2Hz),6.81(m,1H),4.32(s,2H,CH2),1.35(s,9H,tBu),1.32(s,9H,tBu) ,0.96(s,9H,tBuSi),0.19(s,6H,SiMe2).

[0102] 2) Under nitrogen atmosphere, dissolve intermediate A1 (34.9g, 100mmol) in 88.5g of solvent ether, then add n-butyllithium (30.6g, 100mmol), react at -40°C for 30min, then add 6,6- Diphenylfulvene (23g, 100mmol), react at -40°C for 3h, add water and eth...

Embodiment 2

[0109] Preparation of Catalyst M2:

[0110]

[0111] 1) Under nitrogen atmosphere, mix 2-aminomethyl-3,5-di-tert-butylphenol (23.5g, 100mmol) and imidazole (10.2g, 150mmol) in 150.9g tetrahydrofuran, add dimethyl tert-butyl Chlorosilane (16.6g, 110mmol), reacted at 20°C for 1.5h, removed THF under reduced pressure, added 100mL of water and ethyl acetate for extraction and separation, removed ethyl acetate under reduced pressure, column chromatography (eluent volume ratio 10 : 1 petroleum ether and ethyl acetate) to obtain intermediate A1, 34.3g, yield 98%.

[0112] 2) Under a nitrogen atmosphere, the intermediate A1 (34.9g, 100mmol) was dissolved in 332.1g of the solvent methyl tert-butyl ether, then n-butyllithium (45.9g, 150mmol) was added, reacted at -0°C for 45min, and then Add 6,6-diphenylfulvene (29.9g, 130mmol), react at -0°C for 4.5h, add water and ethyl acetate for extraction and separation, column chromatography (the eluent is petroleum ether with a volume ratio ...

Embodiment 3

[0117] Preparation of Catalyst M3:

[0118]

[0119] 1) Under nitrogen atmosphere, mix 2-aminomethyl-3,5-di-tert-butylphenol (23.5g, 100mmol) and imidazole (13.6g, 200mmol) in 276.1g tetrahydrofuran, add dimethyl tert-butyl Chlorosilane (18.12g, 120mmol), reacted at 50°C for 3h, removed THF under reduced pressure, added 100mL of water and ethyl acetate for extraction and separation, removed ethyl acetate under reduced pressure, and performed column chromatography (eluent volume ratio 20: 1 petroleum ether and ethyl acetate) to obtain intermediate A1, 34.3g, yield 98%.

[0120] 2) Under nitrogen atmosphere, the intermediate A1 (34.9g, 100mmol) was dissolved in 653g solvent diethyl ether, then n-butyllithium (61.2g, 200mmol) was added, reacted at 30°C for 60min, and then added fulvene 6,6- Diphenylfulvene (34.5g, 150mmol), react at 30°C for 6h, add water and ethyl acetate for extraction and separation, column chromatography (eluent is petroleum ether and ethyl acetate with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com