Method for measuring calcium oxide in medium manganese slag

A method of determination, the technology of calcium oxide, is applied in the direction of material analysis by observing the influence of chemical indicators, chemical analysis by titration, and analysis by making materials undergo chemical reactions, which can solve the problems of high cost and complexometric titration. , Crucible damage and other problems, to achieve the effect of reducing the cost of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

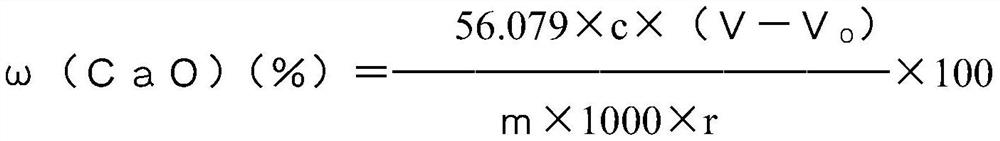

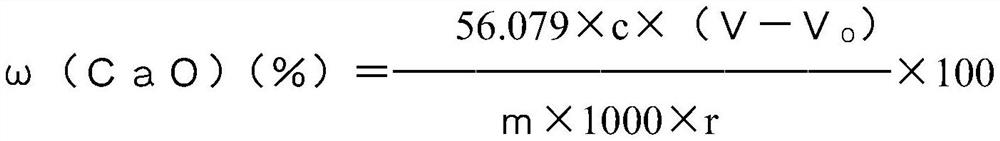

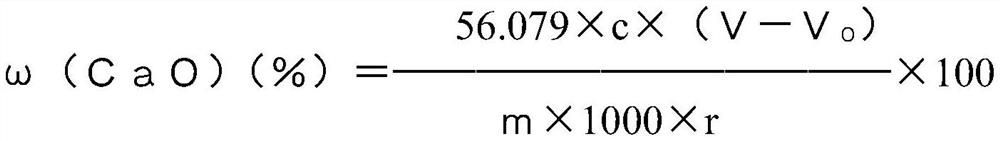

[0027] A kind of assay method of calcium oxide in the manganese slag, comprises the following steps: Step 1: the alkali fusion of sample: the concrete operation of described step 1 is as follows: 0.2000g sample is placed in the crucible that fills sodium peroxide, Stir evenly, cover it in a high-temperature muffle furnace at 700-750°C, melt for 5 minutes, take it out to cool slightly, and rinse the bottom of the crucible with water. The crucible used in step 1 is made of metallic silver.

[0028] Step 2: acidify the sample after alkali fusion in step 1 into the solution to be tested: the specific operation of the step 2 is as follows: immerse the crucible with the melt in the step 1 in a 250mL beaker filled with 100mL water, add 25mL hydrochloric acid (ρ1.18g / mL), heated and boiled for a few minutes, removed the molten material and placed it in a beaker to obtain a test solution, took out the crucible, cooled to room temperature, and washed the crucible and cover with water; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com