Titanium-based composite material with core-shell structure as well as preparation method and application of titanium-based composite material

A technology of titanium-based composite materials and core-shell structure, which is applied in the field of lithium-ion batteries, can solve the problems of inability to guarantee the uniformity of the cladding layer, low diffusion coefficient, and inability to better block the gas production reaction of lithium titanate, and achieve an improvement The effect of first-time charge-discharge efficiency, improved Li+ diffusion coefficient, and excellent first-time charge-discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

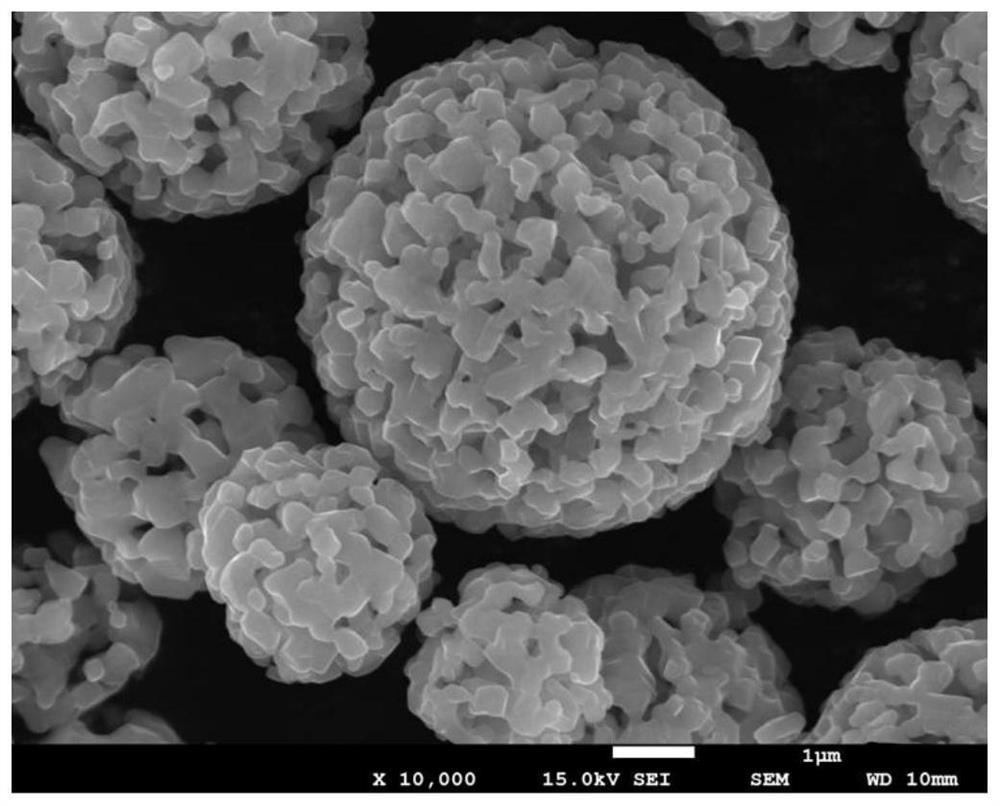

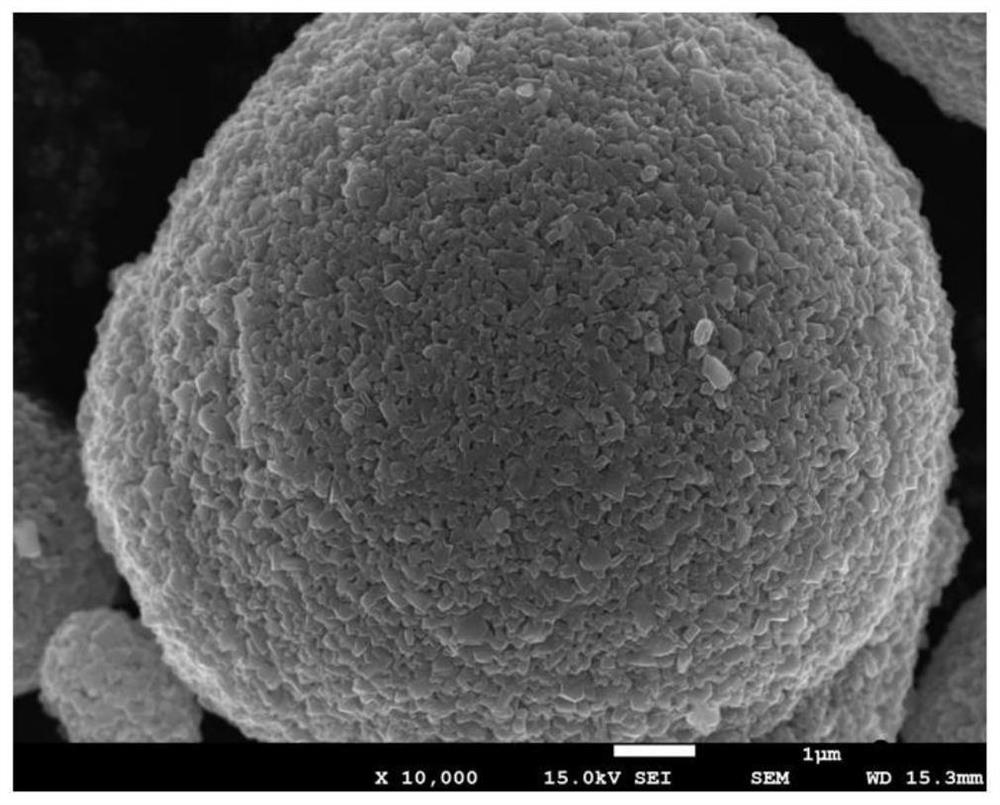

Image

Examples

Embodiment 1

[0050] S1. Add 117.3g of anatase-type titanium dioxide and 396g of niobium pentoxide powder into a sand mill, add water to adjust the solid content to 30%, first grind at 500rpm for 1h, and then grind at a speed of not less than 13m / s Continue to grind for 5 hours, then transfer the grinding slurry and carry out spray drying treatment. The temperature of the spray inlet is 230°C, and the temperature of the outlet is 100°C to obtain a titanium niobate precursor with a median particle size of 3 μm. Then the mixed The titanium niobate precursor was placed in a high-temperature muffle furnace, and after a solid-state reaction at 900°C for 10 hours, titanium niobate particles with a median particle size of 3 μm were finally obtained;

[0051] S2. Dissolve 182.4g cetyltrimethylammonium bromide (CTAB) in 3335.5mL ethylene glycol solution, then add 300.0g titanium niobate particles, stir mechanically at 800rpm for 1h, then add 1111.8mL titanic acid Tetrabutyl ester, continue to stir a...

Embodiment 2

[0056] S1. Add 117.3g of anatase-type titanium dioxide and 396g of niobium pentoxide powder into a sand mill, add water to adjust the solid content to 30%, first grind at 500rpm for 1h, and then grind at a speed of not less than 13m / s Continue to grind for 5 hours, then transfer the grinding slurry and carry out spray drying treatment. The temperature of the spray inlet is 230°C, and the temperature of the outlet is 100°C to obtain a titanium niobate precursor with a median particle size of 3 μm. Then the mixed The titanium niobate precursor was placed in a high-temperature muffle furnace, and after a solid-state reaction at 900°C for 10 hours, titanium niobate particles with a median particle size of 3 μm were finally obtained;

[0057] S2. Dissolve 153.1g cetyltrimethylammonium bromide (CTAB) in 2223.7mL ethylene glycol solution, then add 300.0g titanium niobate particles, mechanically stir at 800rpm for 1h, then add 741.2mL titanic acid Tetrabutyl ester, continue to stir an...

Embodiment 3

[0062] S1. Add 117.3g of anatase-type titanium dioxide and 396g of niobium pentoxide powder into a sand mill, add water to adjust the solid content to 30%, first grind at 500rpm for 1h, and then grind at a speed of not less than 13m / s Continue to grind for 5 hours, then transfer the grinding slurry and carry out spray drying treatment. The temperature of the spray inlet is 230°C, and the temperature of the outlet is 100°C to obtain a titanium niobate precursor with a median particle size of 3 μm. Then the mixed The titanium niobate precursor was placed in a high-temperature muffle furnace, and after a solid-state reaction at 900°C for 10 hours, titanium niobate particles with a median particle size of 3 μm were finally obtained;

[0063] S2. Dissolve 255.4g cetyltrimethylammonium bromide (CTAB) in 5003.3mL ethylene glycol solution, then add 300.0g titanium niobate particles, mechanically stir at 800rpm for 1h, then add 1667.8mL titanic acid Tetrabutyl ester, continue to stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com