Application of functional oligosaccharide to improvement of ductility of dough

A functional oligosaccharide and oligosaccharide technology, applied in the field of flour product processing, can solve the problems of high cost of L-cysteine and protease, damage to food nutrients, instability, etc., and achieve stable properties, easy storage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 200g wheat flour is placed in the noodle pot, the water of 95g is mixed with 4g functional oligosaccharides (functional oligosaccharides are 15% xylooligosaccharides, 35% galactooligosaccharides and 50% isomaltooligosaccharides), Turn on the dough mixer while adding water to the noodle pot, stir at 60rpm for 2min, then continue to stir at 100rpm for 5min, then stir at 60rpm for 3min to obtain functional oligosaccharide dough.

[0033] The stretching distance of the prepared functional oligosaccharide dough was 81.42±1.59mm.

Embodiment 2

[0035] Put 200g of wheat flour in the kneading pot, mix 95g of water with 2g, 4g, 6g, 8g, 10g of functional oligosaccharides, start the kneading machine while adding water to the kneading pot, stir at 60rpm for 2min, then 100rpm Continue to stir for 5min, then stir at 60rpm for 3min to obtain functional oligosaccharide dough.

[0036] In order to explore the effect of different functional oligosaccharides on the stretchability of dough, the functional oligosaccharides were selected from xylooligosaccharides, galactooligosaccharides, fructooligosaccharides, isomaltooligosaccharides, stachyose, and gentiooligosaccharides. , raffinose and cyclodextrins.

[0037] The extensibility of the prepared functional oligosaccharide dough is shown in Table 1, and the dough without adding the functional oligosaccharide was used as a blank control. The analysis found that among the 8 kinds of prebiotics, xylo-oligosaccharides, galacto-oligosaccharides, fructo-oligosaccharides and isomalto-ol...

Embodiment 3

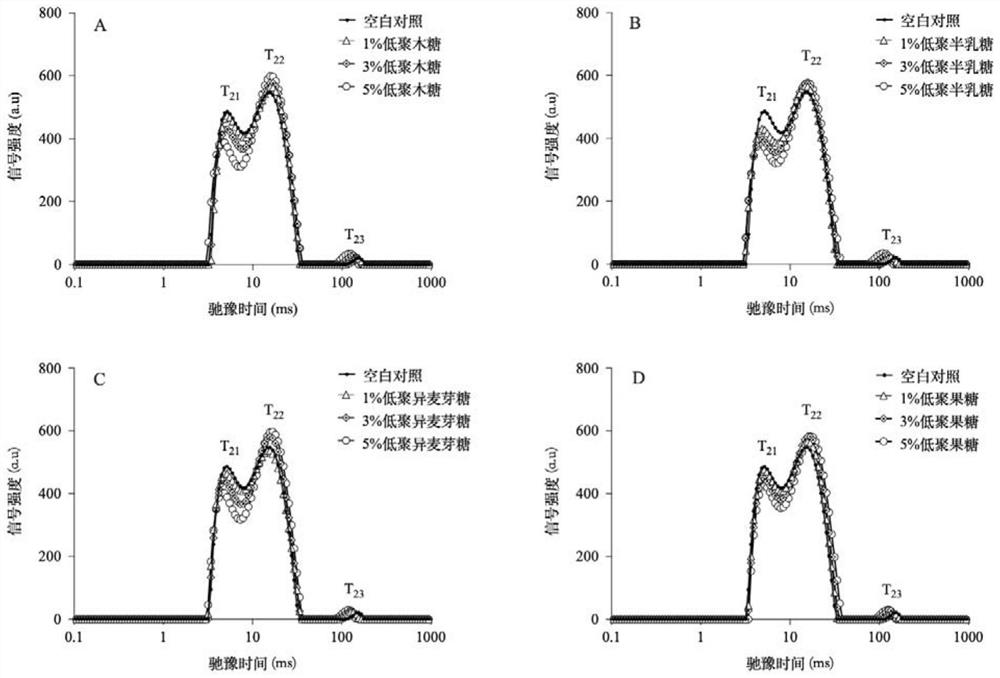

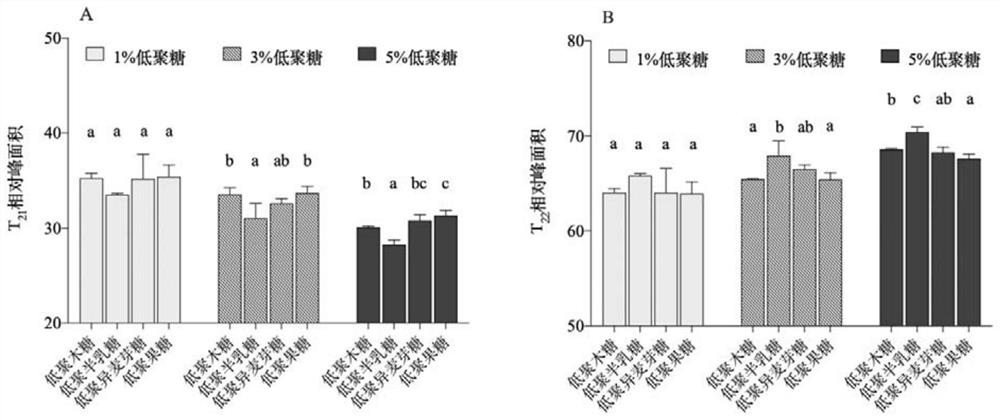

[0042] Xylo-oligosaccharides, galacto-oligosaccharides, fructo-oligosaccharides and isomalto-oligosaccharides are easily soluble in water and have strong water holding capacity. Adding them to wheat dough will definitely affect the binding state and distribution of water molecules in the dough , which may be the key to the influence of oligosaccharides on dough extensibility.

[0043] Put 200g of wheat flour in the kneading pot, mix 95g of water with 2g, 6g, and 10g of functional oligosaccharides, start the kneading machine while adding water to the kneading pot, stir at 60rpm for 2min, then continue stirring at 100rpm for 5min. Then stir at 60rpm for 3min to obtain functional oligosaccharide dough.

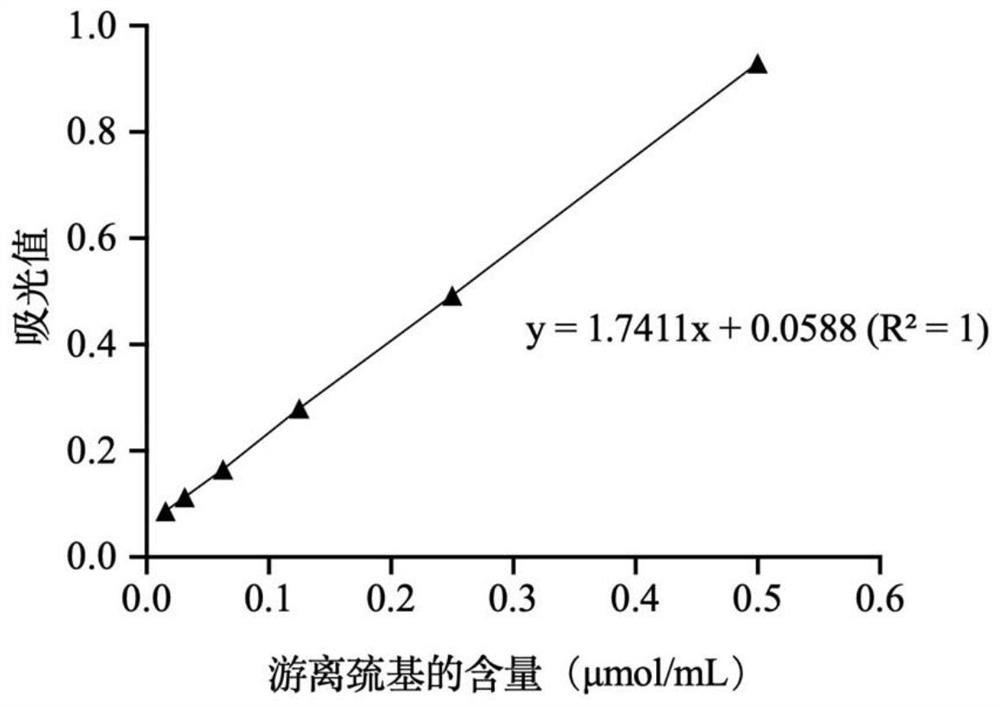

[0044] Analyze the binding state and distribution of water molecules in functional oligosaccharide dough. Four kinds of functional oligosaccharides were used in this experiment, namely xylooligosaccharides, isomaltooligosaccharides, galactooligosaccharides and fructooligosacchar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com