Marine algae fermentation product and preparation method thereof

A technology of fermented products and marine algae, applied to bacteria used in food preparation, yeast-containing food ingredients, food ingredients, etc., can solve the problems of oyster smell left behind and low acceptance by eaters, and achieve easy absorption by the human body and significant Outstanding economic and social benefits and health care effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

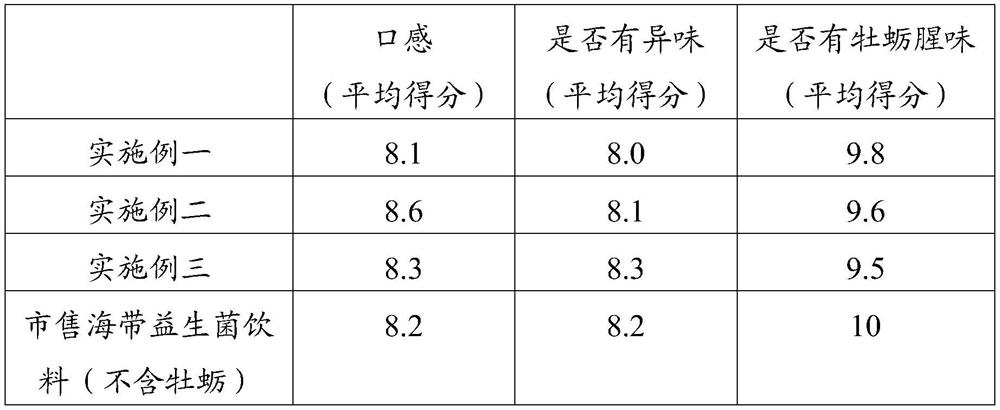

Examples

preparation example Construction

[0014] The invention provides a method for preparing a marine algae fermentation product, comprising the steps of:

[0015] (1) With the following raw materials in parts by weight: 50-60 parts of Hijiki, 20-30 parts of kelp, 10-20 parts of Spirulina platensis, 10-20 parts of Haematococcus pluvialis, 10-20 parts of laver and 10- 20 parts of fresh tea leaves, ripened and deodorized to obtain a raw material mixture, and enzymatically hydrolyzed the raw material mixture to obtain a seaweed mixed enzymatic hydrolysis solution;

[0016] (2) enzymatically hydrolyzing oyster meat to obtain oyster enzymatic hydrolyzate, which is spray-dried to obtain oyster peptide;

[0017] (3) Mix the seaweed mixed enzymatic hydrolyzate and oyster peptide at a weight ratio of 1:0.03-0.05 to obtain a mixed solution, add 1-2% lactose and 1-2% mixed fermentation bacteria in the mixed solution mass percentage, and mix at 30 Ferment at -35°C for 24-36 hours to obtain a mixed fermentation broth; the mixed...

Embodiment 1

[0043] A method for preparing a marine algae fermentation product, comprising the steps of:

[0044] (1) The following raw materials in parts by weight include: 50 parts of Hijiki, 20 parts of kelp, 10 parts of Spirulina platensis, 10 parts of Haematococcus pluvialis, 10 parts of laver and 10 parts of fresh tea leaves, the above fresh or dried After rehydrating the raw material, wash and remove impurities, heat in steam at 80°C for 5 minutes.

[0045] After the raw material mixture is drained, an equal volume of water is added and ground into a slurry with a colloid mill to obtain a seaweed slurry;

[0046] The seaweed slurry is subjected to ultrasonic-assisted enzymolysis to obtain a mixed enzymolysis solution, the added enzyme is a mixed enzyme of alkaline protease and papain; the weight ratio of alkaline protease and papain in the mixed enzyme is 1:1, The added amount of the mixed enzyme is 0.5% of the total weight of raw materials, the temperature of enzymolysis is 45-55°...

Embodiment 2

[0058] A method for preparing a marine algae fermentation product, comprising the steps of:

[0059] (1) The following raw materials by weight include: 55 parts of Hijiki, 25 parts of kelp, 15 parts of Spirulina platensis, 15 parts of Haematococcus pluvialis, 15 parts of laver and 15 parts of fresh tea leaves, the above fresh or dried After rehydrating the raw materials, wash and remove impurities, heat them in steam at 83°C for 15 minutes.

[0060] After the raw material mixture is drained, an equal volume of water is added and ground into a slurry with a colloid mill to obtain a seaweed slurry;

[0061] The seaweed slurry is subjected to ultrasonic-assisted enzymolysis to obtain a mixed enzymolysis solution, the added enzyme is a mixed enzyme of alkaline protease and papain; the weight ratio of alkaline protease and papain in the mixed enzyme is 1:1.5, The added amount of the mixed enzyme is 1% of the total weight of raw materials, the temperature of enzymolysis is 50° C., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com