Preparation method and application of unidirectional titanium carbide aerogel

A titanium carbide and aerogel technology, which is applied in titanium carbide, chemical instruments and methods, carbides, etc., to achieve the effects of broad application prospects, simple preparation methods and strong reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

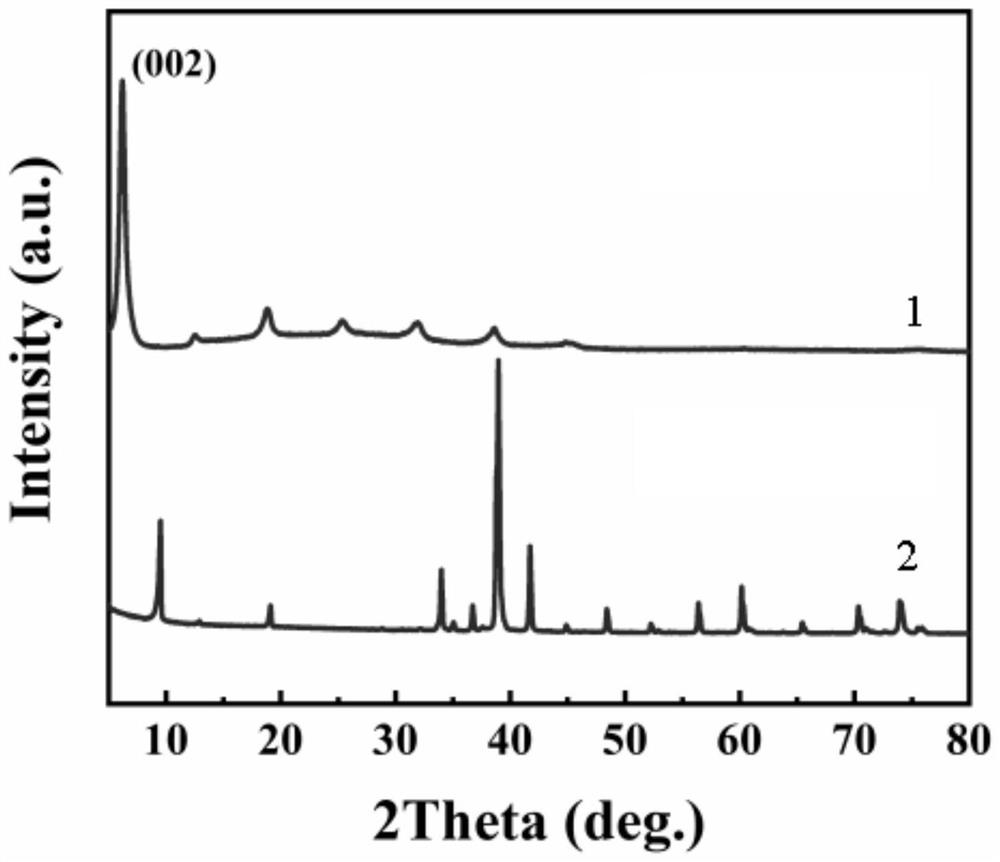

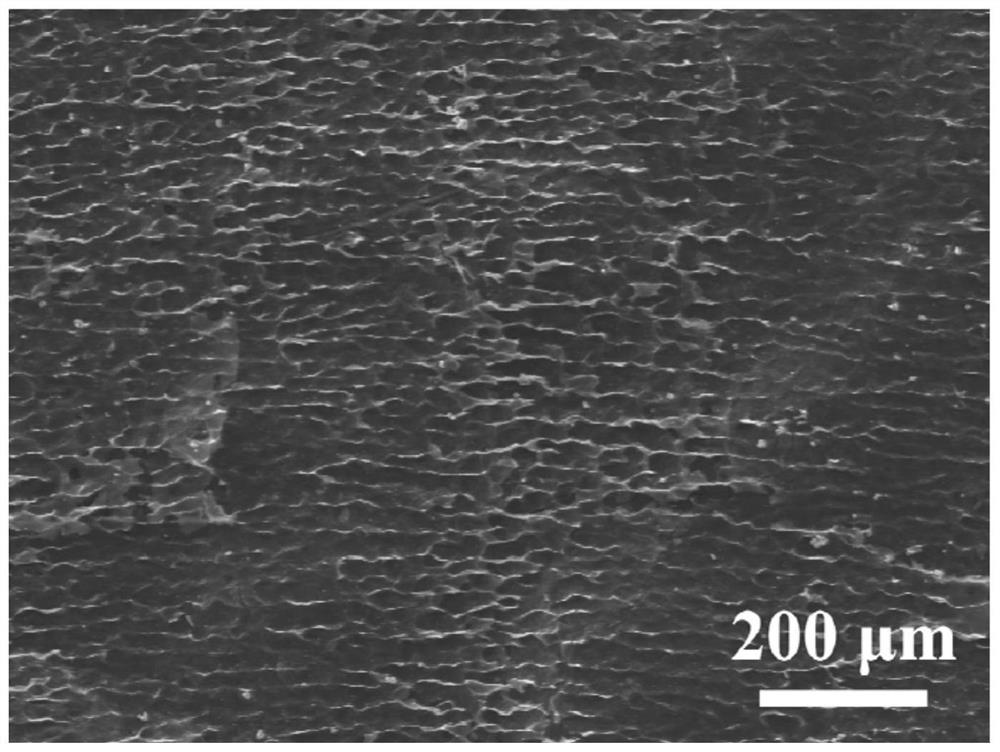

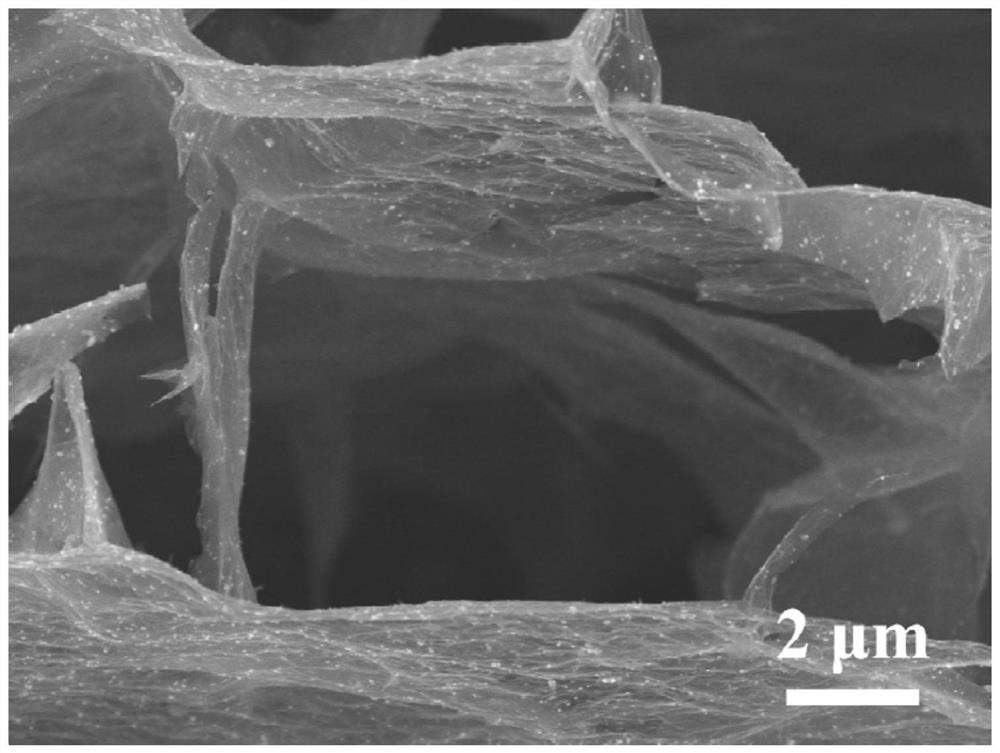

[0025] Embodiment 1: The preparation method of the unidirectional titanium carbide airgel in this embodiment is implemented according to the following steps:

[0026] 1. Add 1~2g LiF into 20~25mL concentrated HCl solution and stir, then add Ti in several times 3 AlC 2 The powder is stirred and reacted in a water bath under the heating condition of 30-45°C to obtain a reaction liquid;

[0027] Two, the reaction solution obtained in step one is centrifuged, and the solid phase precipitate is collected;

[0028] 3. First use the HCl aqueous solution with a mass concentration of 3% to 5% at 7000 to 9000r / min to centrifuge and wash the solid phase precipitate several times, and then use a LiCl aqueous solution with a mass concentration of 3% to 5% at 7000 to 9000r / min The solid-phase sediment was centrifuged and washed several times in 1 min, and then deionized water was added for washing, and repeated several times until the pH value of the supernatant was 5-7, then the speed of...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass concentration of the concentrated HCl solution described in step 1 is 36% to 38%.

specific Embodiment approach 3

[0035] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the water bath stirring reaction time in step 1 is 40-60 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com