Wear-resistant anti-sticking coating for food machinery and preparation method of wear-resistant anti-sticking coating

A technology for anti-stick coatings and food machinery, applied in the field of coatings, can solve the problems of poor weather resistance and easy aging of high-hardness coatings, achieve excellent hydrophobic anti-stick properties, improve overall compatibility, and good storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

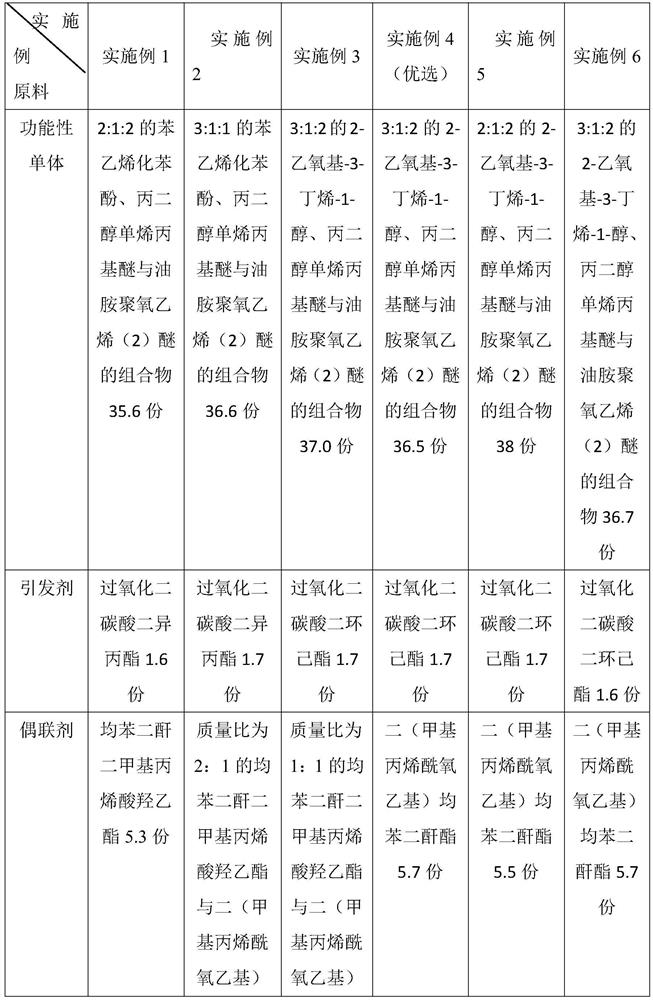

[0038] A wear-resistant and anti-stick coating for food machinery and a preparation method thereof, which is formed by polymerization of the following components, the total mass of raw materials is 100 parts, and each component includes:

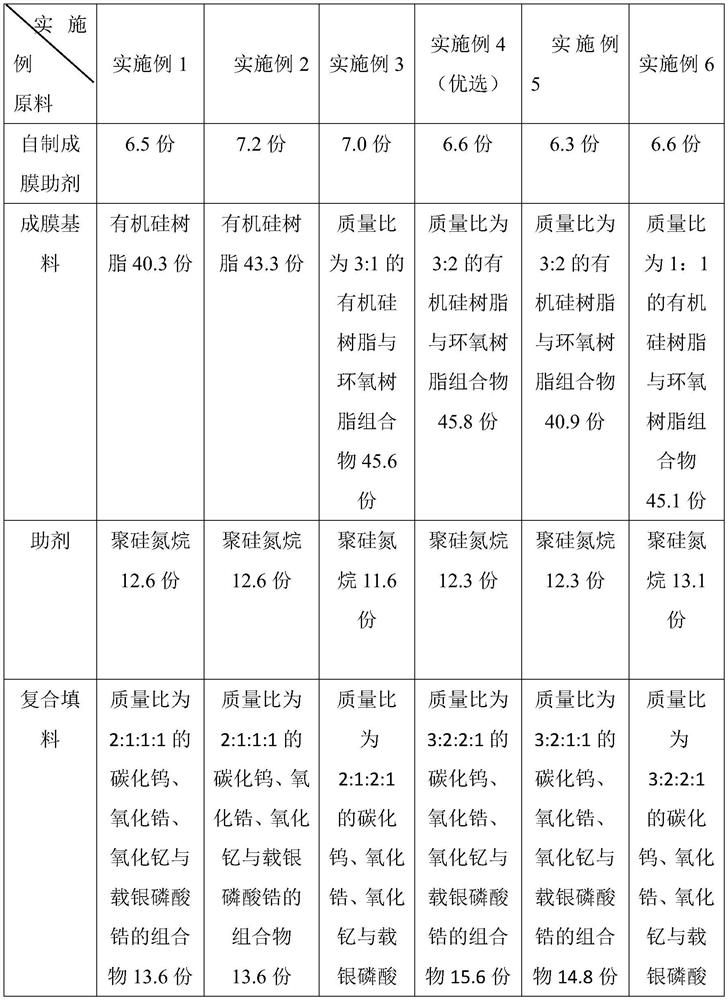

[0039]6.5 parts of self-made leveling dispersion stabilizer;

[0040] 40.3 parts of silicone resin;

[0041] 12.6 parts of polysilazane;

[0042] 5.3 parts of hydroxyethyl pyrphthalic anhydride dimethacrylate;

[0043] 13.6 parts of compositions of tungsten carbide, zirconia, yttrium oxide and silver-loaded zirconium phosphate with a mass ratio of 2:1:1:1;

[0044] 2.6 parts of emulsified silicone oil;

[0045] 1.9 parts of picoline;

[0046] The balance is water, and the total mass is 100 parts.

[0047] The described wear-resistant and anti-stick coating for food machinery and its preparation method is characterized in that the preparation process includes the following steps in sequence:

[0048] Step 1: Self-made leveling dispersio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com