Heat and sound insulation cotton felt for large aircraft

A technology of heat insulation and sound insulation, large aircraft, applied in the direction of fuselage insulation, etc., can solve the problems of being susceptible to moisture and affecting performance, and achieve the effect of excellent hydrophobicity and improved hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0029] Embodiments 1 to 4: A heat-insulating and sound-insulating cotton blanket for a large aircraft, which is formed by curing and drying glass fibers sprayed with an adhesive;

[0030] The adhesive is composed of the following components by weight, as shown in Table 1:

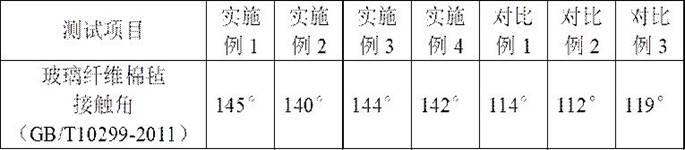

[0031] Table 1

[0032] ;

[0033] Described modified phenolic resin solution obtains through the following steps:

[0034] Step 1. Formaldehyde is added to the mixture composed of phenol, xylenol, and lignin, and reacted at a temperature of 40-60°C to obtain the first solution. The weight ratio of phenol, xylenol, and lignin is 10 :2~4:1~8;

[0035] Step 2. Add sodium hydroxide aqueous solution to the first solution to adjust the pH of the first solution to 8~9, and raise the temperature to 75~85°C for 1~2h, then cool down to 35~50°C, add sulfuric acid and stir obtaining a second solution;

[0036] Step 3, adding hexamethylol melamine in 3 equal batches to the second solution to obtain the modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com