Zinc-plating-free high-strength angle steel and production method thereof

A production method and galvanizing-free technology, applied in metal rolling and other directions, can solve the problems of difficult bolt connection construction, uneven stress on angle steel, and increase the cost of iron towers, and achieve high corrosion resistance, improved strength, and improved deformation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

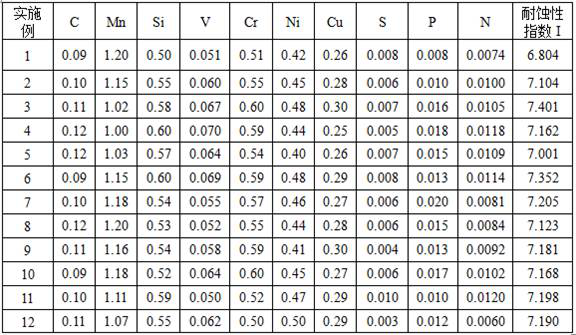

Embodiment 1-12

[0022] A galvanized-free high-strength angle steel, the chemical composition and mass percentage of which are C: 0.09-0.12%, Mn: 1.00-1.20%, Si: 0.50-0.60%, V: 0.05-0.07%, Cr: 0.50-0.60 %, Ni: 0.40~0.50%, Cu: 0.25~0.30%, S≤0.010%, P: 0.008~0.020%, N: 0.0060~0.0120%, the balance is Fe and unavoidable impurities, corrosion resistance index I ≥6.7.

[0023] The production method of the above-mentioned galvanized-free high-strength angle steel includes converter smelting, LF refining, continuous casting, heating, rolling, cooling, sawing and cutting to length, spraying labels, and warehousing processes;

[0024] (1) Converter smelting process: Copper and nickel plates are added to the converter along with scrap steel; Mn and Si are alloyed with silicon-manganese alloy; parts with insufficient Si content are filled with ferrosilicon; Cr is alloyed with low-carbon ferrochromium;

[0025] (2) LF refining process: V uses vanadium nitrogen alloy for microalloying to ensure the N conte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap