Modified calcium-boron-lanthanum glass powder, green tape, dielectric constant controllable LTCC substrate, packaging material and preparation method thereof

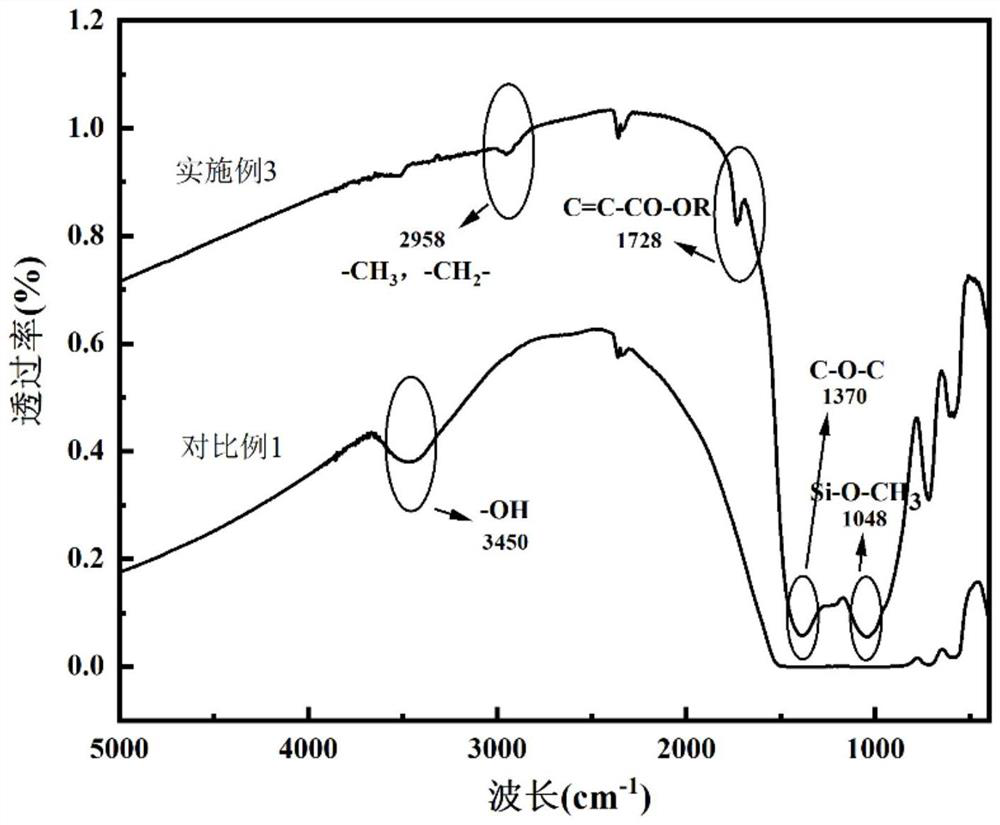

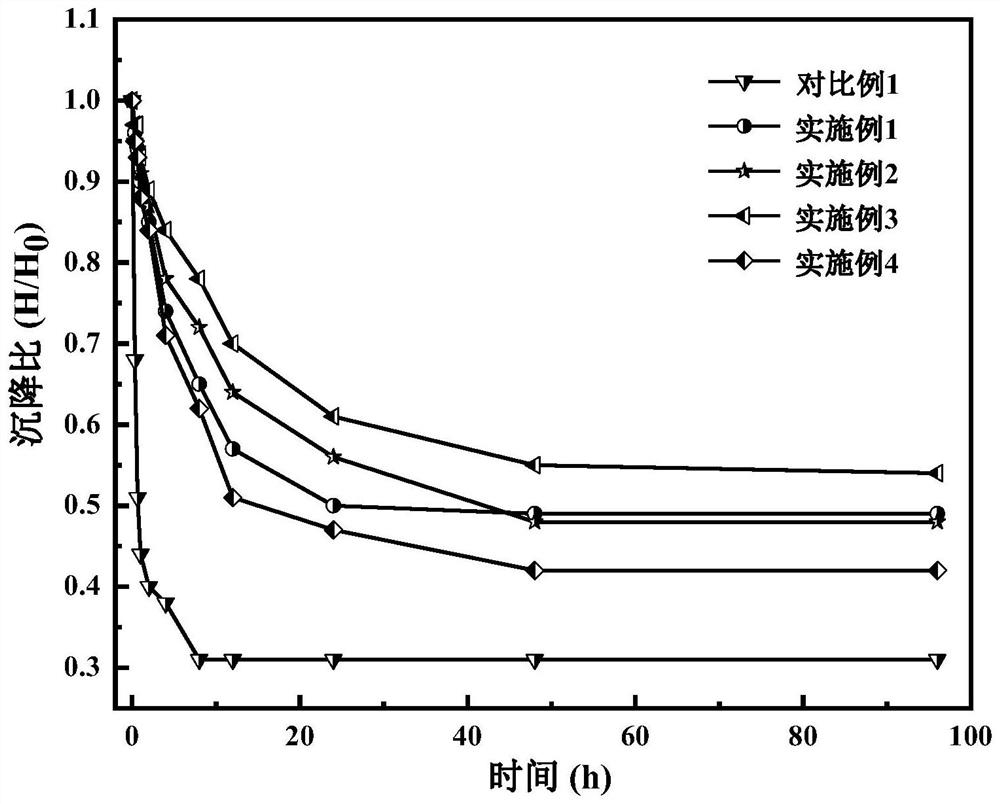

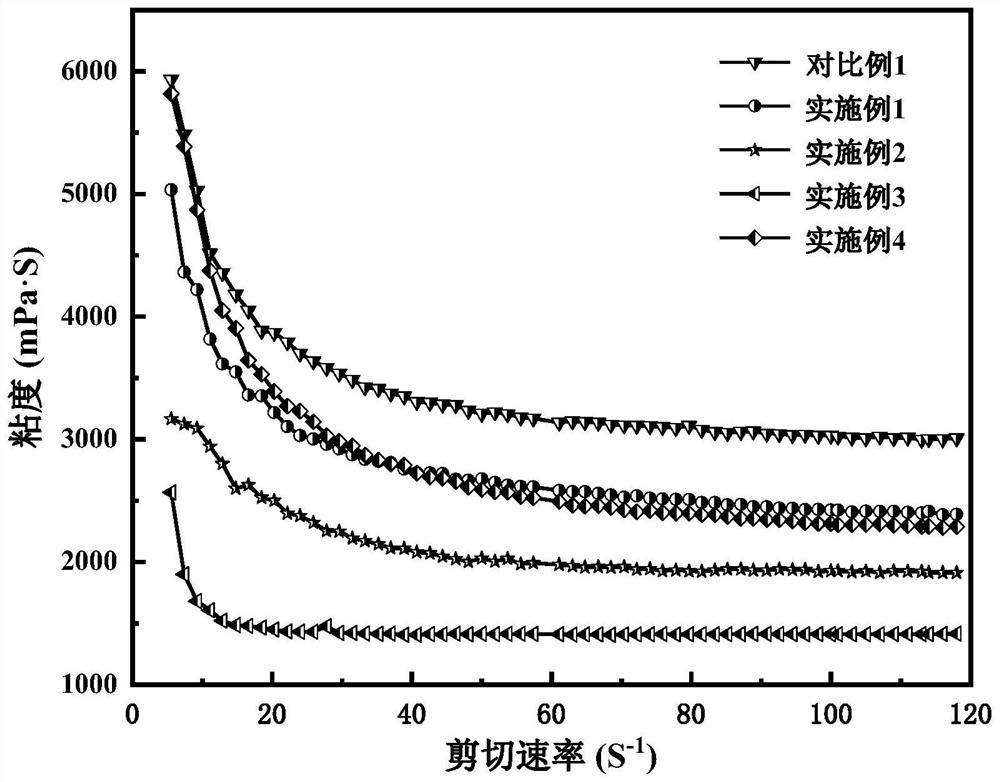

A dielectric constant and glass powder technology, which is applied in the field of glass powder surface modification, can solve problems such as unfavorable powder dispersion, and achieve the effects of enhanced powder suspension stability, good suspension stability, and improved substrate densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Some embodiments of the present invention provide a method for preparing a modified calcium boron lanthanum glass powder, comprising the following steps:

[0046] S1 Mix the surface modifier, water, absolute ethanol and acid-base regulator to obtain a mixed solution with a pH value of 1-5, and stir the mixed solution to obtain a dissolved surface modifier solution;

[0047] S2 mixes the calcium boron lanthanum glass powder, the dissolved surface modifier solution obtained in step S1, water, absolute ethanol and an acid-base regulator to obtain a mixed solution with a pH value of 3-6, and stir the mixed solution to modify properties, followed by ultrasonic cleaning, drying and sieving to obtain the modified calcium boron lanthanum glass powder.

[0048] In the above-mentioned technical solution, in step S1, wherein the mass percentage of the water in the first mixed solution is 25-45wt%; by controlling the ratio of water to the first mixed solution in the range of 25-45w...

Embodiment 1

[0076] This example provides a method for preparing a LTCC substrate with a controllable dielectric constant. The specific steps are as follows: (1) Preparation of modified powder: use an electronic balance to weigh 25g of water and 50g of absolute ethanol and add it to a pre-dried In a 250ml beaker, mix well, then weigh 0.5g surface modifier KH-570 with an electronic balance and add them to the above beaker, then add acetic acid to adjust the pH value of the mixed solution to 3.5. Place the beaker in a magnetic stirrer and stir at room temperature 25°C for 2 hours. When there are no obvious suspension beads and no stratification in the liquid in the beaker, it means that the stirring is over. In addition, weigh 100 g calcium boron lanthanum glass powder (its composition and molar ratio is: the molar ratio of each component of the glass powder is: CaO: 20.0%, B 2 o 3 : 52.0%, La 2 o 3 : 15.0%, SiO 2 : 2.8%, NaCO 3 : 4.2%, P 2 o 5 : 6.0%; particle size is 1.7 microns) in...

Embodiment 2

[0080] This example provides a method for preparing an LTCC substrate with a controllable dielectric constant. The difference between it and Example 1 is that the amount of the surface modifier KH-570 is 1 g.

[0081] The 48h sedimentation ratio H / H of the modified calcium boron lanthanum glass powder prepared in this example in ethyl acetate 0 It is 0.46, and the Zeta potential in the acidic environment of pH=6 is 16.7; the heat loss in the air atmosphere of 850°C is 0.89%; the particle size is 1.3 microns. The batch of LTCC substrates thus prepared has a dielectric constant of 6.37-6.42 at 12-18 GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com