Special water-permeable concrete for water-permeable brick and water-permeable brick prepared from concrete

A technology of permeable concrete and permeable bricks, applied in the field of concrete, can solve the problems of broken bricks, poor strength, loosening and disintegration of gravel, etc., and achieve the effect of high porosity, high connected porosity and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

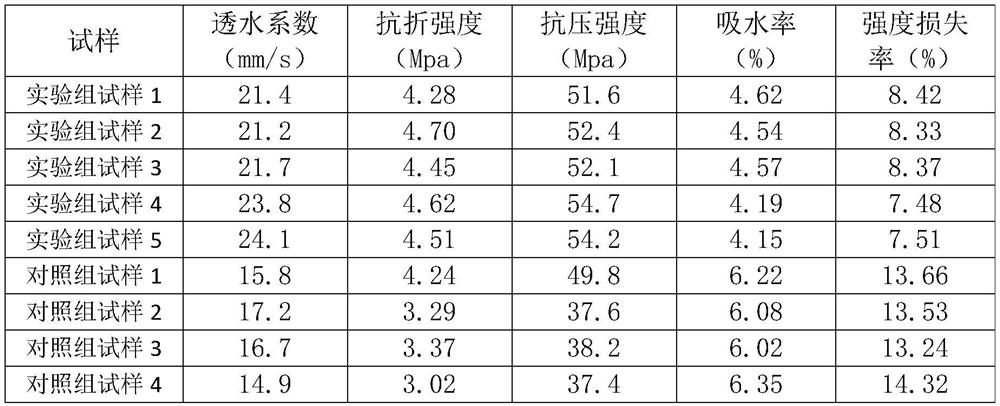

Examples

Embodiment 1

[0041] A special permeable concrete for permeable bricks, the raw materials of which include cement, water, crushed stones, fillers, defoamers and cementing agents, wherein the particle size of the crushed stones is between 4-7mm, and the fillers are fumed silica, Polyester fiber and diatomite, the defoamer is Sanpin Technology's SP-6103 polyether defoamer, and the binder is polytrimethylene carbonate, diacetone acrylamide and hydroxypropyl acrylate.

[0042] The specific dosage of raw materials is as follows:

[0043] Cement 118kg, water 60kg, gravel 372kg, fumed silica 23kg, polyester fiber 8kg, diatomaceous earth 16kg, polyether defoamer 5kg, epoxy resin 25kg, polytrimethylene carbonate 12kg, diacetone acrylamide 3kg, 3.5kg of hydroxypropyl acrylate.

Embodiment 2

[0045] A special permeable concrete for permeable bricks, its raw materials are consistent with those in Example 1, and the specific dosage of its raw materials is as follows:

[0046] 120kg of cement, 60kg of water, 375kg of gravel, 22kg of fumed silica, 9kg of polyester fiber, 15kg of diatomaceous earth, 4kg of polydimethylsiloxane, 30kg of epoxy resin, 14kg of polytrimethylene carbonate, diacetone Acrylamide 2.8kg, hydroxypropyl acrylate 3.2kg.

Embodiment 3

[0048] A special permeable concrete for permeable bricks, the raw materials of which include cement, water, crushed stones, fillers, defoamers and cementing agents, wherein the particle size of the crushed stones is between 4-7mm, and the fillers are fumed silica, Polyester fiber and diatomaceous earth, the defoamer is BASF's SI-2292 polydimethylsiloxane based defoamer, and the binder is polytrimethylene carbonate, diacetone acrylamide and hydroxypropyl acrylate.

[0049] The specific dosage of raw materials is as follows:

[0050] Cement 114kg, water 58kg, gravel 367kg, fumed silica 20kg, polyester fiber 8kg, diatomaceous earth 14kg, polydimethylsiloxane 4kg, epoxy resin 22kg, polytrimethylene carbonate 12kg, diacetone Acrylamide 2.7kg, hydroxypropyl acrylate 3kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com