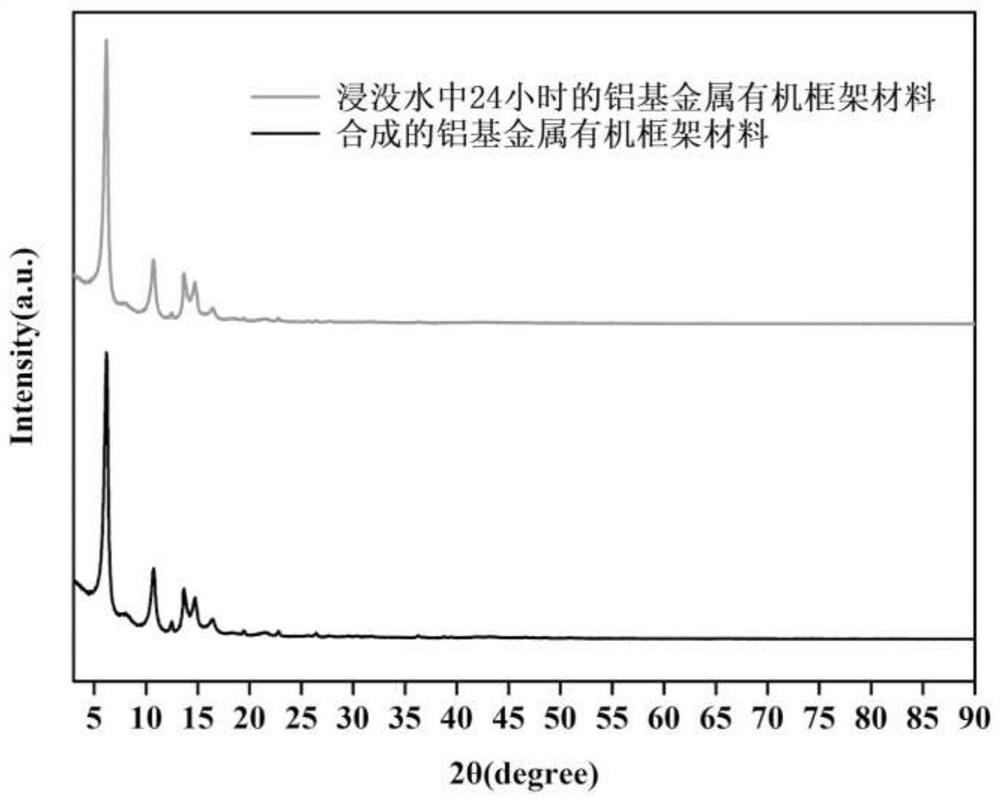

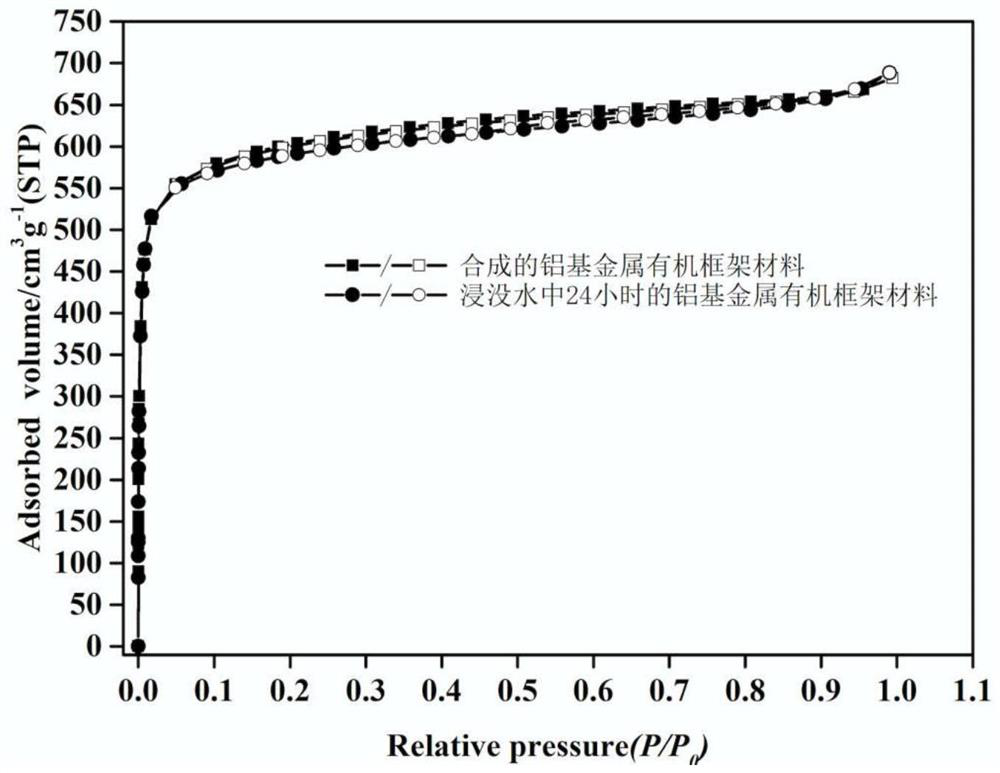

Preparation method of microporous aluminum-based metal organic framework material with high specific surface area and water stability

A high specific surface area, organic framework technology, applied in the field of adsorption material research and development, can solve problems such as collapse, and achieve the effect of low biological toxicity, maintaining structural stability and rich content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

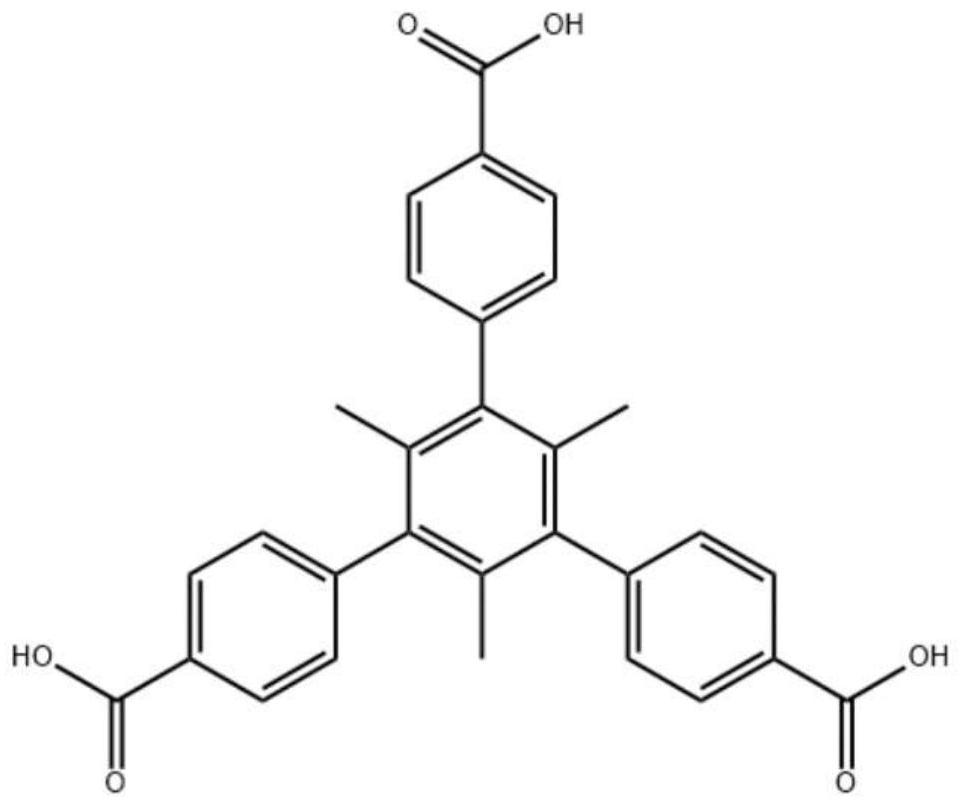

[0023] Weigh 104mg of aluminum nitrate nonahydrate and 300mg of 1,3,5-trimethyl-2,4,6-tris(4-carboxyphenyl)benzene (molar ratio is 0.44:1) and place in 15mL of N, In N-dimethylformamide (DMF) organic solution, 1.4 mL of formic acid was added dropwise, and the reactants were completely dissolved and dispersed evenly after ultrasonication for 30 minutes. The reactants were placed in a reaction kettle and sealed. Set the oven temperature to 130 degrees Celsius, and the reaction time to 72 hours. After the reaction was completed, the reaction kettle was cooled to room temperature, the reaction product and mother liquor were transferred to a centrifuge tube, separated by centrifugation, and the supernatant was poured off to obtain the crude product at the bottom. Then wash with N,N-dimethylformamide and acetone for 3 to 4 times in sequence, and put the washed product into a vacuum drying oven to dry, and finally obtain a high specific surface area and water-stable microporous alum...

Embodiment 2

[0025] Weigh 208mg of aluminum nitrate nonahydrate and 300mg of 1,3,5-trimethyl-2,4,6-tris(4-carboxyphenyl)benzene (molar ratio is 0.88:1) and place in 15mL of N, In N-dimethylformamide (DMF) organic solution, 1.7 mL of formic acid was added dropwise, and ultrasonication was performed for 30 minutes, so that the reactants were completely dissolved and uniformly dispersed. The reactants were placed in a reaction kettle and sealed. Set the oven temperature to 130 degrees Celsius, and the reaction time to 72 hours. After the reaction was completed, the reaction kettle was cooled to room temperature, the reaction product and mother liquor were transferred to a centrifuge tube, separated by centrifugation, and the supernatant was poured off to obtain the crude product at the bottom. Then wash with N,N-dimethylformamide and acetone for 3 to 4 times in sequence, and put the washed product into a vacuum drying oven to dry, and finally obtain a high specific surface area and water-sta...

Embodiment 3

[0027] Weigh 200mg of aluminum nitrate nonahydrate and 69mg of 1,3,5-trimethyl-2,4,6-tris(4-carboxyphenyl)benzene (molar ratio is 0.44:1) and place in 10mL of N, In N-dimethylformamide (DMF) organic solution, 1.0 mL of formic acid was added dropwise, and ultrasonication was performed for 30 minutes, so that the reactants were completely dissolved and uniformly dispersed. The reactants were placed in a reaction kettle and sealed. Set the oven temperature to 130 degrees Celsius, and the reaction time to 72 hours. After the reaction was completed, the reaction kettle was cooled to room temperature, the reaction product and mother liquor were transferred to a centrifuge tube, separated by centrifugation, and the supernatant was poured off to obtain the crude product at the bottom. Then wash with N,N-dimethylformamide and acetone for 3 to 4 times in sequence, and put the washed product into a vacuum drying oven to dry, and finally obtain a high specific surface area and water-stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com