Carbon microsphere, hydrotalcite and polyphosphazene hybrid flame retardant and preparation method thereof

A technology of carbon microspheres and hydrotalcite, which is applied in the flame retardant field of polyolefin matrix materials, can solve the problems of poor mechanical properties and low flame retardant efficiency, reduce the deterioration of mechanical properties, improve flame retardant properties, and improve carbon formation Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

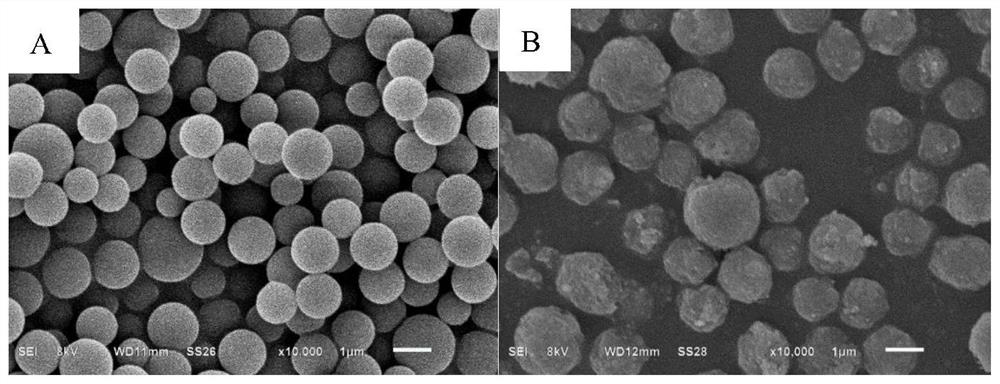

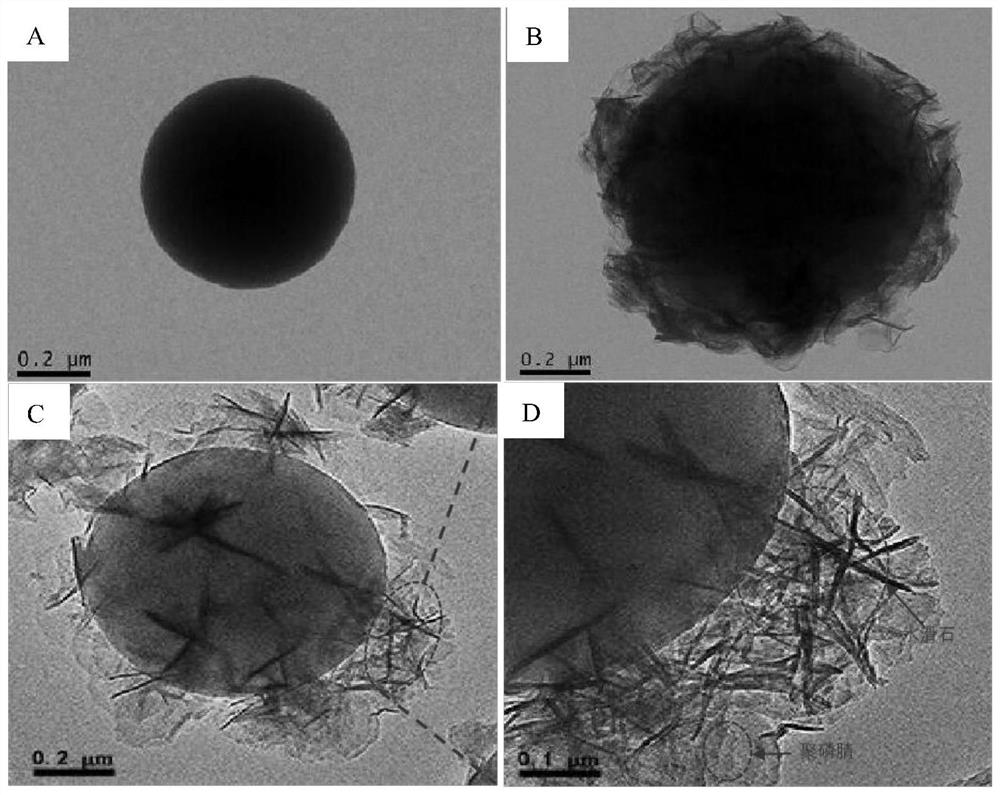

[0031] (1) Configure 400m L concentration as 0.4mol L -1 The aqueous glucose solution was transferred to a hydrothermal reaction kettle with a capacity of 500mL for hydrothermal reaction. The reaction temperature was 160°C and the reaction time was 8h. After the reaction was completed, it was cooled and filtered, and the filtered black solid was washed several times with absolute ethanol. , until the filtrate is clear and transparent, then wash with deionized water until the pH of the filtrate is neutral, put the filter cake in a vacuum oven, dry at 100°C for 6 hours, and then grind it evenly and seal it for storage. The prepared sample carbon The microspheres are recorded as CMSs, and the SEM results are shown in figure 1 (A), The surface of CMSs is smooth, the outline is clear, and the particle size distribution is relatively uniform, but the dispersion of CMSs itself is poor.

[0032] (2) Weigh 2g of CMSs and dissolve it in 100mL of absolute ethanol, and transfer it to a 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com