Super-amphiphobic material with hydrophobic migration and self-repairing performance and preparation method of super-amphiphobic material

A hydrophobic migration and super-amphiphobic technology, applied in polyester coatings, coatings, electrical components, etc., can solve the problems that the local area cannot exhibit super-hydrophobic properties, does not have super-hydrophobicity, and local wetting of RTV insulators. , to achieve the effects of excellent hydrophobicity, simple coating process, and improved pollution flashover voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

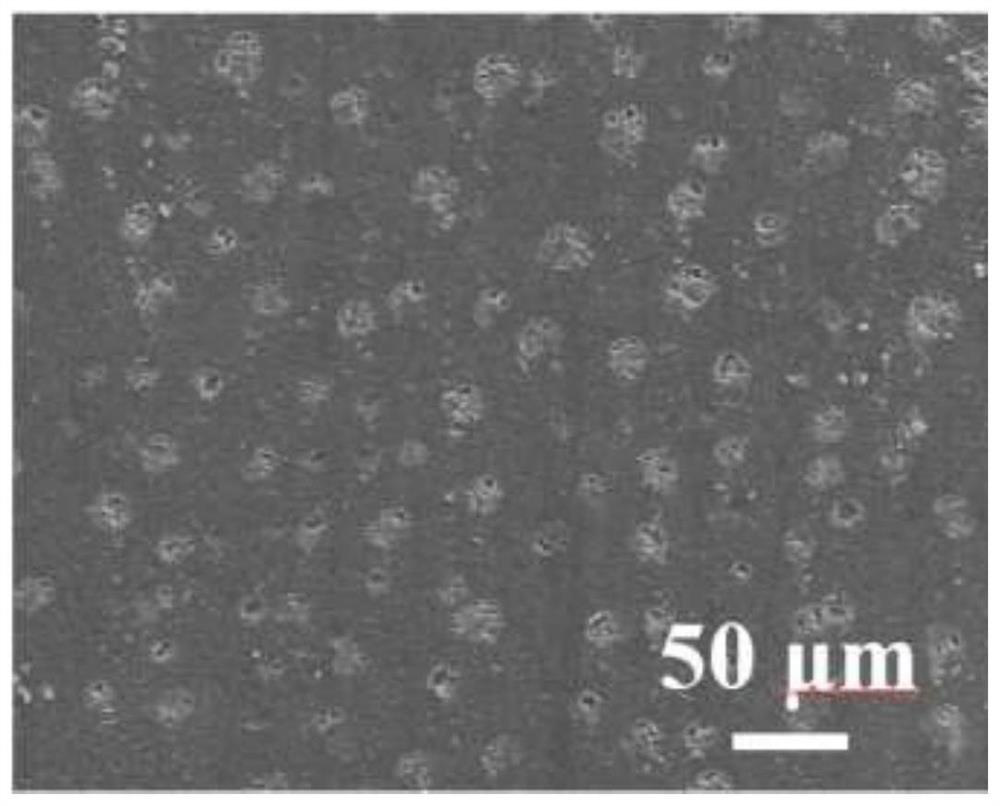

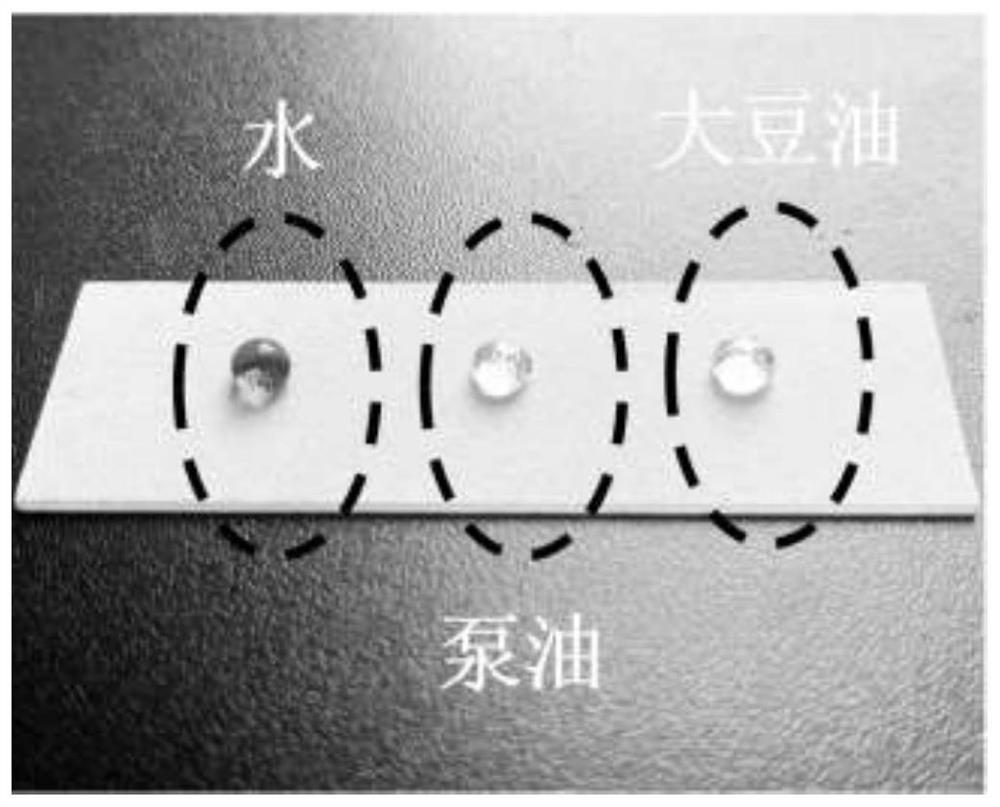

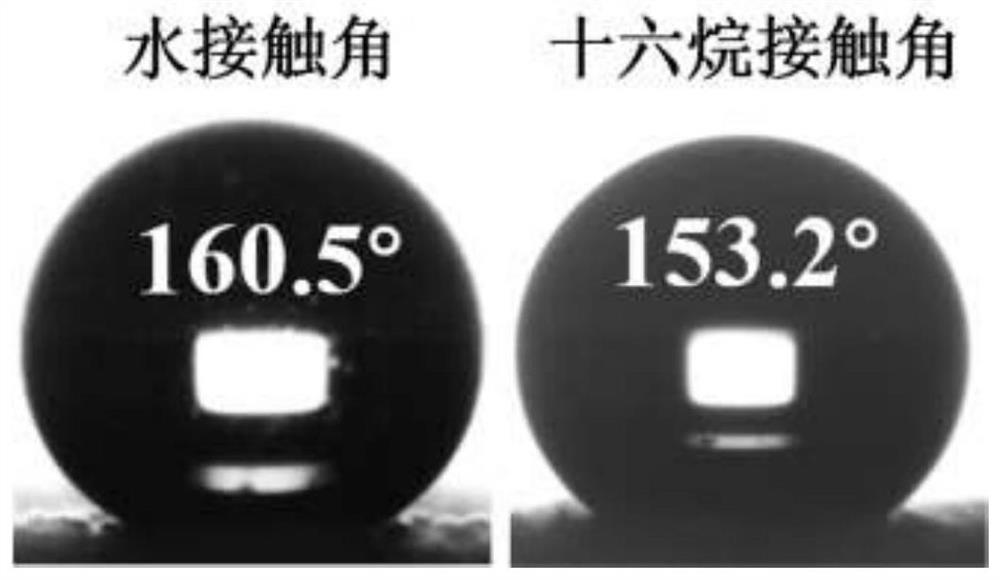

[0058] A superhydrophobic superoleophobic film with hydrophobic migration and self-healing properties, the preparation method of which comprises the following steps:

[0059] 1) Under the condition of magnetic stirring, add 4 mL of NaOH aqueous solution with a concentration of 0.08 g / mL to 100 mL of ethanol, and slowly pour 20 mL of tetraethyl orthosilicate into 100 mL of ethanol after stirring for 5 minutes, hydrolyze at room temperature for 4 hours to obtain a silicon dispersion, and statically Place and age for 2 days;

[0060] 2) 6.5ml concentration of 20vol% H 2 SO 4 Slowly add the aqueous solution to the silicon dispersion prepared in step 1), stop the reaction after stirring for 1 hour, and let stand for 4 hours;

[0061] 3) Take 0.45ml of perfluorodecyltrimethoxysilane, and evenly disperse it in 8.55ml of ethanol, then uniformly add the above dispersion into the silica sol prepared in step 2), and react for 2h under the condition of magnetic stirring to obtain Super...

Embodiment 2

[0071] A superhydrophobic superoleophobic film with hydrophobic migration and self-healing properties, the preparation method of which comprises the following steps:

[0072] 1) Under the condition of magnetic stirring, add 6 mL of NaOH aqueous solution with a concentration of 0.08 g / mL to 100 mL of ethanol, and slowly pour 20 mL of tetraethyl orthosilicate into 100 mL of ethanol after stirring for 5 minutes, hydrolyze at room temperature for 4 hours to obtain a silicon dispersion, and statically Place and age for 2 days;

[0073] 2) 13ml of HNO with a concentration of 0.165g / mL 3 The aqueous solution is slowly added to the silicon dispersion prepared in step 1), and the reaction is stopped after stirring for 10 minutes;

[0074] 3) Take 0.55ml of perfluorodecyltrimethoxysilane, and evenly disperse it in 8.45ml of ethanol, then add the above-mentioned dispersion evenly into the silica sol prepared in step 2), and react for 2h under the condition of magnetic stirring to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com