High-temperature-resistant fireproof heat-insulating coating and preparation method thereof

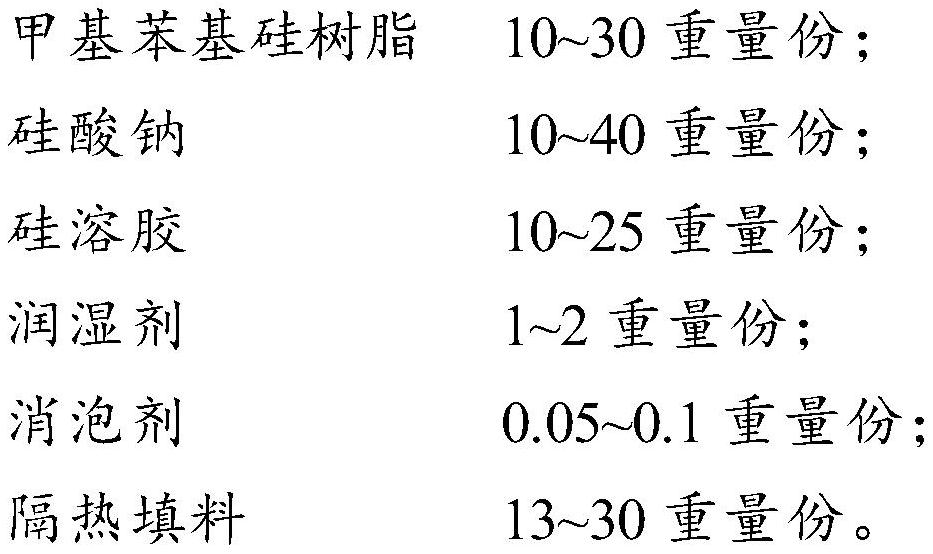

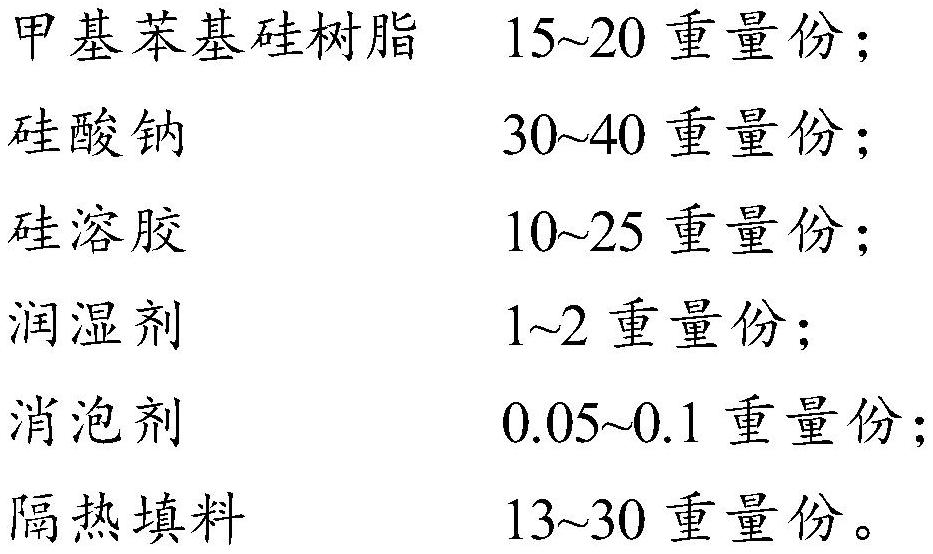

A heat-insulating coating and high-temperature-resistant technology, applied in fire-resistant coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of lack of adhesion, difficulty in achieving flame retardant and fire resistance, and achieve improved adhesion, good The effect of fire resistance and thermal insulation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing the above-mentioned high-temperature-resistant fireproof and heat-insulating coating, which includes: mixing silica sol and sodium silicate, adding methylphenyl silicone resin, then adding wetting agent and defoamer, stirring and mixing After uniformity, heat-insulating fillers are added to obtain high-temperature-resistant fire-proof and heat-insulating coatings.

[0032] Wherein, the contents and types of the silica sol, sodium silicate, methylphenyl silicone resin, wetting agent, defoamer and heat-insulating filler are the same as those described above, and will not be repeated here.

[0033] The present invention also provides an application of the above-mentioned high-temperature-resistant fire-proof and heat-insulating coating in heat preservation of equipment below 600°C.

[0034] The present invention also provides a method for using the above-mentioned high-temperature-resistant fire-proof and heat-insu...

Embodiment 1

[0038] First add quantitative silica sol and sodium silicate into the beaker, then add quantitative methylphenyl silicone resin while stirring, then add wetting agent and defoamer, after stirring evenly, add ceramic microspheres, glass microspheres in turn and rutile titanium dioxide. After being completely stirred evenly, a high-temperature-resistant fireproof and heat-insulating coating can be obtained.

[0039] The formula is: 20% methyl phenyl silicone resin, 40% sodium silicate, 15% silica sol, 1% wetting agent alkyl polyether, 0.05% defoamer, 5% ceramic microspheres, 15% glass microspheres , rutile titanium dioxide 3.95%.

Embodiment 2

[0041] The preparation method is the same as in Example 1, except that the formula is: 15% methylphenyl silicone resin, 40% sodium silicate, 20% silica sol, 1% wetting agent alkyl polyether, and 0.05% defoamer , ceramic microspheres 5%, glass microspheres 15%, rutile titanium dioxide 3.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com