Steel for oil well pipe, preparation method of steel and oil well pipe

A technology for oil well pipes and pipes, which is applied in the field of preparation of oil well pipes and steel for oil well pipes. It can solve the problems that high strength and high toughness, high strength and SSC resistance can not be satisfied at the same time, so as to improve the SSC resistance and increase molybdenum Content, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

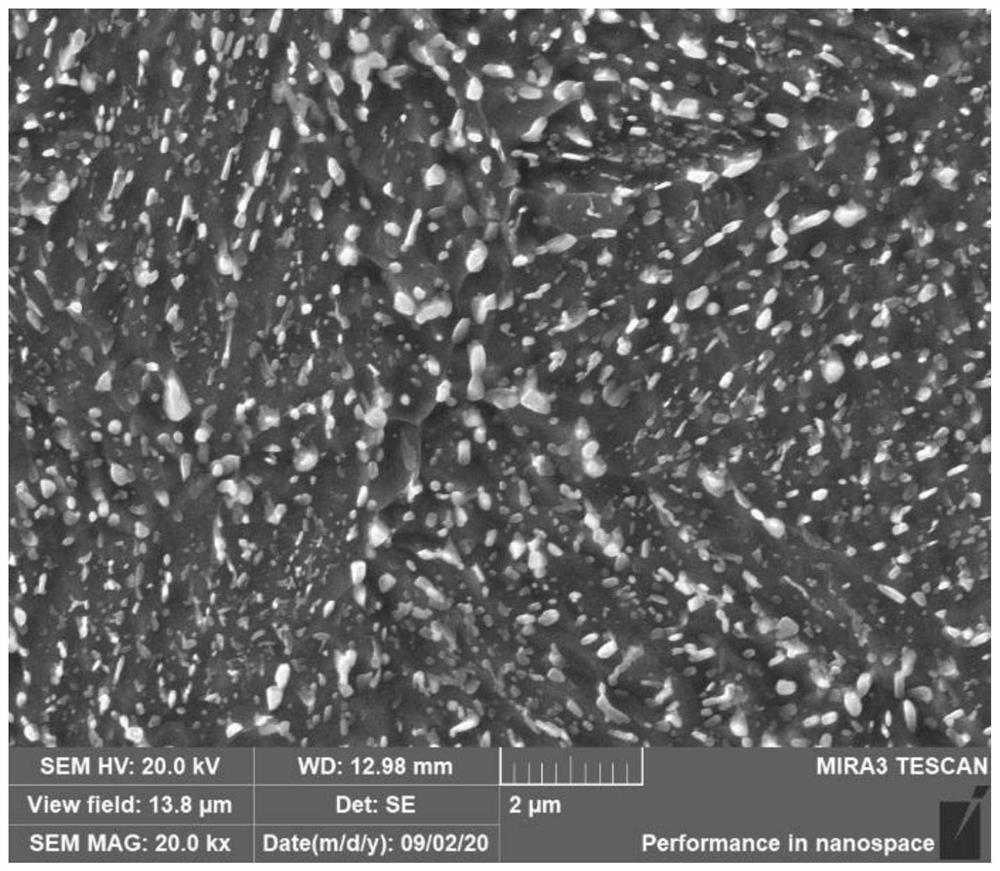

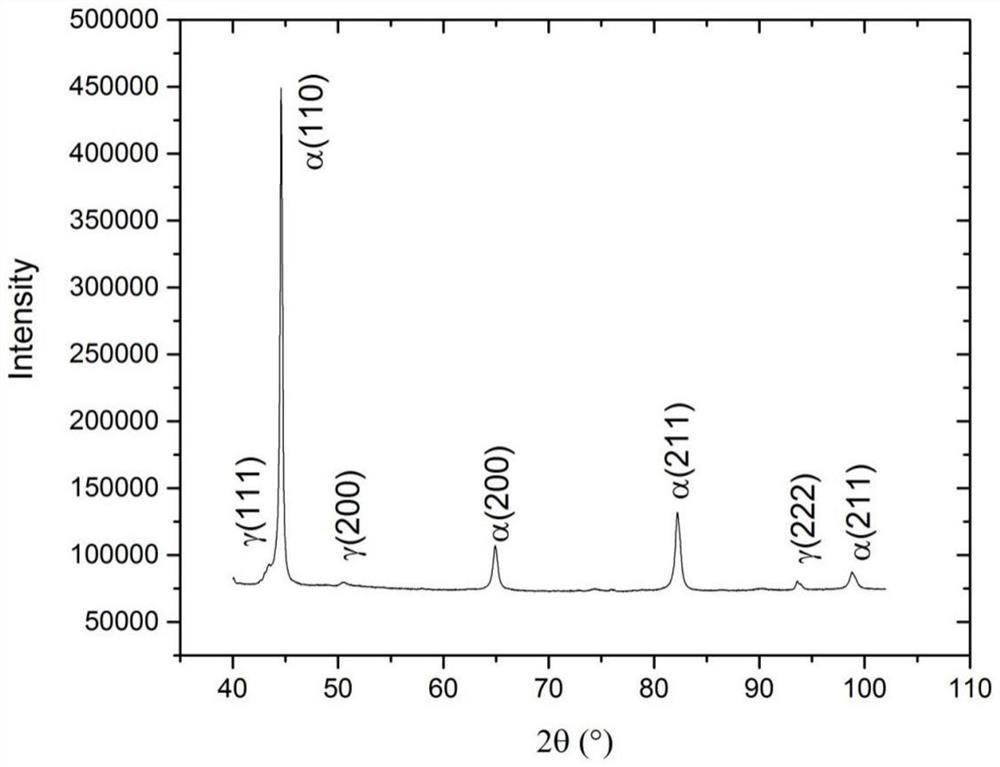

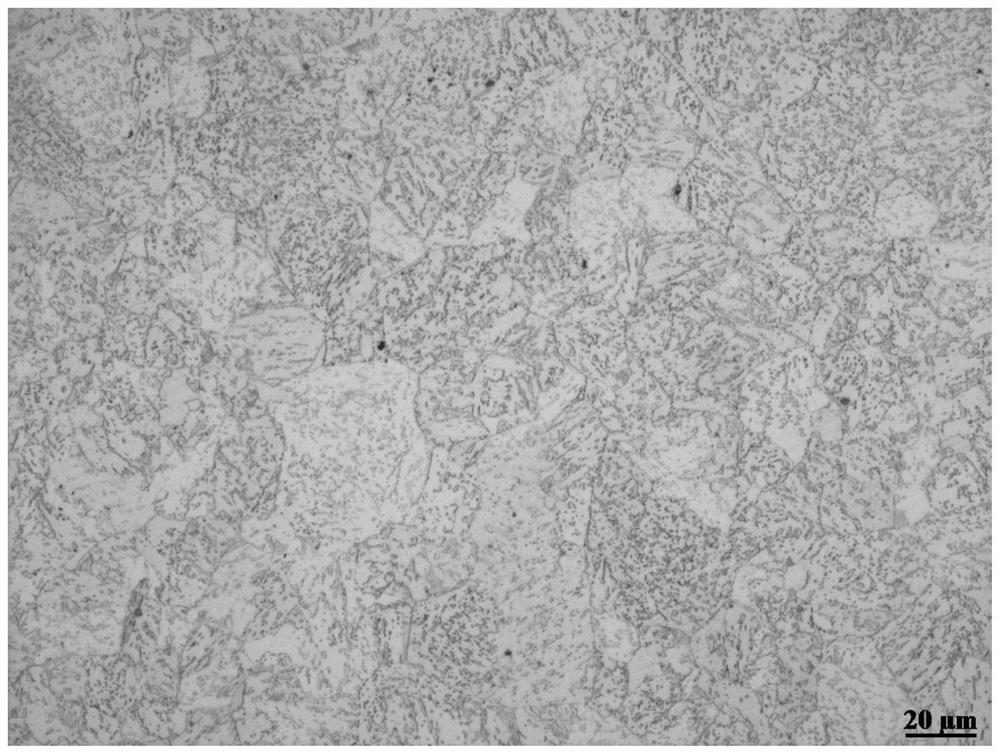

[0052] In another typical embodiment of the present application, a method for preparing the above steel for oil well pipe is provided, the preparation method includes: Step S1, mixing materials according to the chemical composition of the above steel for oil well pipe to obtain raw materials, and smelting the raw materials and pouring to obtain a steel ingot; step S2, heat the steel ingot, then forge it in the austenite single-phase region and cool it to room temperature to obtain a cooled steel ingot; step S3, heat treat the cooled steel ingot to obtain oil well pipe steel.

[0053] According to the chemical composition of the steel for oil well pipes mentioned above, the corresponding process is adopted in the preparation method, so as to obtain the steel for oil well pipes with high strength, high toughness and SSC resistance; at the same time, through the cooling process in the heat treatment process, the metallographic structure is controlled. Composition, thereby reducing...

Embodiment 1

[0096] In terms of weight percentage, the chemical composition of steel is: C 0.45%, Si 0.21%, Mn 0.42%, Cr 0.99%, Mo 0.76%, V 0.11%, Nb 0.01%, Al 0.025%, N 0.018%, S 0.001% , P 0.009%, Cu0.99%, Ni 0.62%, wherein Ni / Cu=0.62; the balance is Fe.

[0097] The preparation method is as follows:

[0098] (1) Mix raw materials according to the above chemical components, and obtain steel ingots through vacuum induction smelting and pouring;

[0099] (2) above-mentioned steel ingot is kept warm at 1160 ℃, and the holding time is 8 hours;

[0100] (3) Forge the steel ingot in the austenite single-phase region: the initial forging temperature is 1100°C, the initial forging time is 20min, the final forging temperature is 980°C, the final forging time is 15min, the forging ratio is 10, and air-cooled to room temperature after forging , the cooling rate is 5°C / s.

[0101] (4) Cut a cylindrical steel sample with a diameter of 20mm and a thickness of 20mm for heat treatment: first, the ste...

Embodiment 2

[0103] Different from Example 1, the tempering temperature in step (4) is 710° C., the tempering coefficient is 6.0, and the tempering time is 120 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com