Ion battery electrode plate and preparation method thereof, device for preparing ion battery electrode plate and ion battery

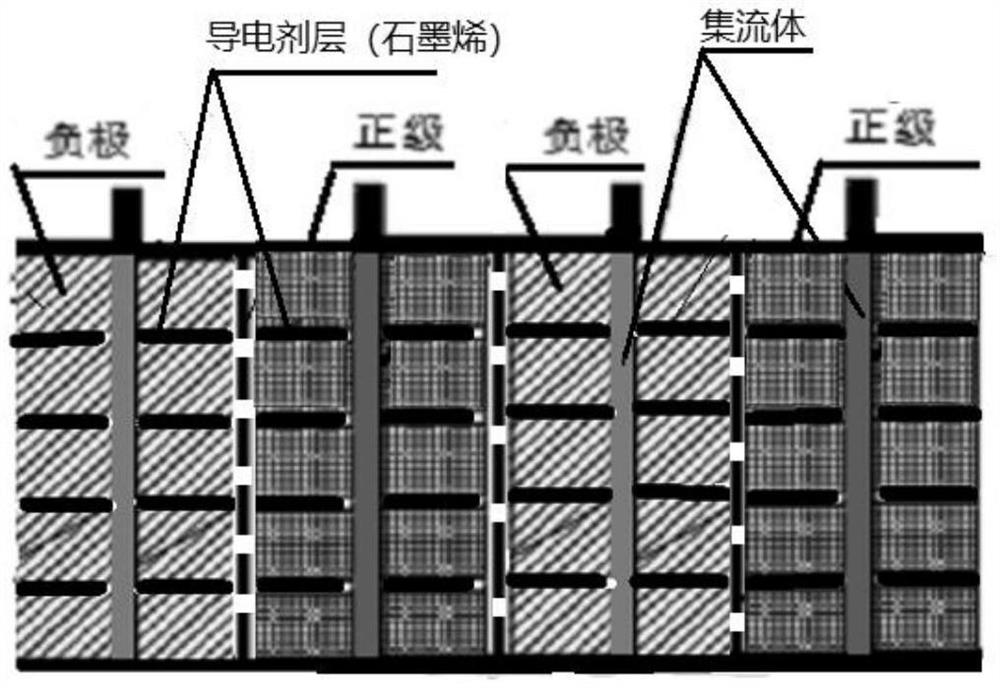

An ion battery and electrode sheet technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., can solve the problems such as the inability to exert the conductive advantages of carbon-based low-dimensional materials and the poor conductivity of the positive and negative electrode sheets of the battery. Achieve the effect of reducing material cost, reducing battery internal resistance, and reducing battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

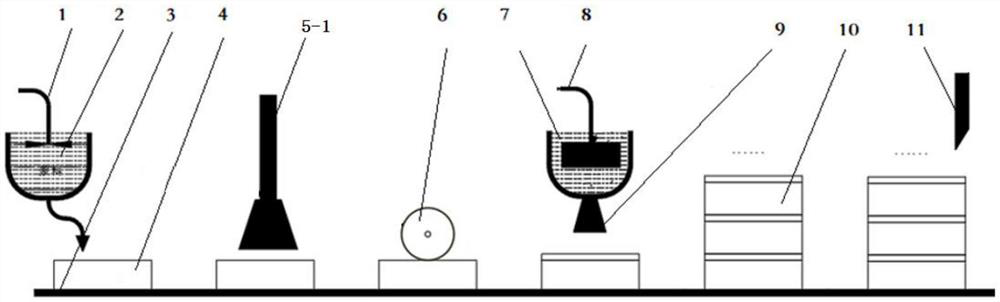

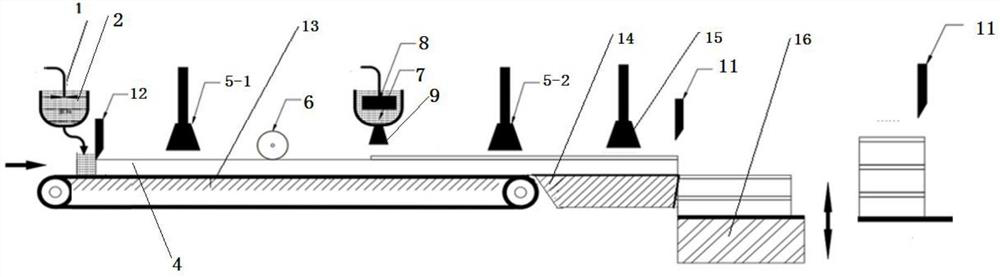

[0063] The present invention provides a method for preparing battery electrode sheets described in the above technical solution, comprising the following steps:

[0064] Spray the conductive agent slurry treated by ultrasonic atomization on the surface of the substrate to form a wet film of the conductive agent slurry. The thickness of the wet film of the conductive agent slurry is ≤5 μm. After the diluent is volatilized, the conductive agent is oriented and oriented during the volatilization process to form an oriented conductive agent layer;

[0065] Or use in-situ vapor deposition to deposit a layer of directional conductive agent on the surface of the substrate;

[0066] The thickness of the single-layer directional conductive agent layer is less than 5 μm;

[0067] The substrate includes a separable substrate, a positive electrode material layer or a negative electrode material layer;

[0068] When the number of layers of the conductive agent layer>1 layer, repeat the p...

Embodiment 1

[0167] Mix lithium iron phosphate and PVDF evenly to obtain a mixture, and then mix it with N-methylpyrrolidone for 2 hours to obtain a positive electrode material slurry, wherein the mass percentage of lithium iron phosphate is 30%, and the mass ratio of lithium iron phosphate to PVDF is 8 :1;

[0168] Graphene nanosheets with a particle size of 3-10nm and N-methylpyrrolidone are mixed in a mass ratio of 2:8 and then mixed with an ultrasonic diffuser to obtain a conductive agent compound;

[0169] use figure 2 The shown device absorbs the PET release film on the coating machine platform 3;

[0170] Put the cathode material slurry into the electrode material bin 2, coat it on the PET release film, and coat it into a film with a thickness of 100 microns;

[0171] Dry with an infrared dryer 5-1 to volatilize and release N-methylpyrrolidone;

[0172] On the platform 3 of the coating machine, use a pressure roller 6 to roll, and the compression amount is 10% to 30%;

[0173] ...

Embodiment 2

[0176] Mix graphite and PVDF evenly to obtain a mixture, and then mix with N-methylpyrrolidone for 2 hours to obtain a negative electrode material slurry, wherein the mass percentage of lithium iron phosphate is 30%, and the mass ratio of lithium iron phosphate to PVDF is 8:1 ;

[0177] The preparation method of the negative electrode sheet is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com