Preparation method of layered quaternary positive electrode material of lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of general discharge capacity of quaternary materials, large percentage of irreversible capacity, affecting the morphology and capacity of materials, and achieve the first irreversible capacity. Low percentage, low percentage of irreversible capacity, effect of reducing time cost and energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of layered quaternary cathode material for lithium ion battery

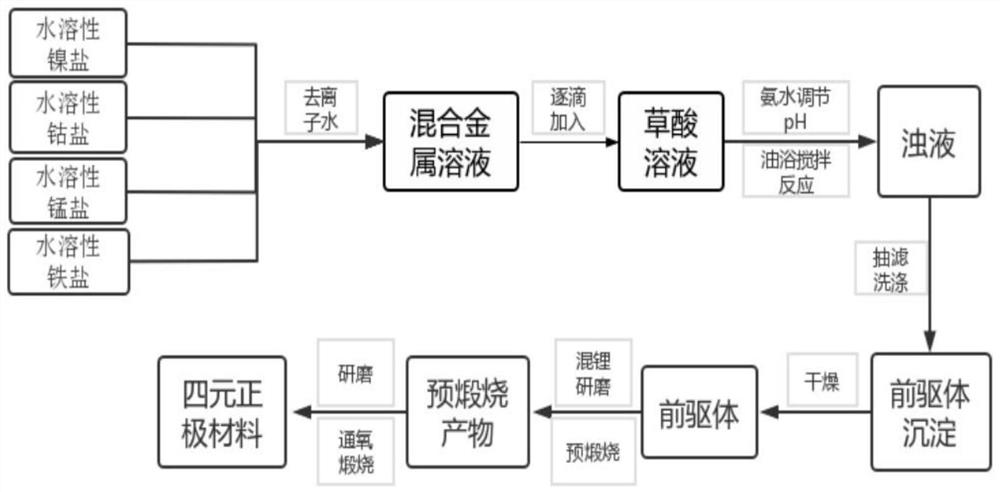

[0029] according to figure 1 The process flow chart of the process, using soluble metal salts as raw materials to prepare the quaternary cathode material LiNi with a layered structure for lithium-ion batteries by co-precipitation 0.6 co 0.08 mn 0.24 Fe 0.08 o 2 , the method includes the following steps:

[0030] (1) Configuration solution:

[0031] First take the water-soluble nickel salt tetrahydrate nickel acetate (C 4 h 14 NiO 8 ), water-soluble diamond salt tetrahydrate cobalt acetate (C 4 h 14 CoO 8 ), water-soluble manganese salt tetrahydrate manganese acetate (C 4 h 14 MnO 8 ), water-soluble iron salt heptahydrate ferrous sulfate (FeSO 4 ·7H 2 (0), and be configured into a mixed metal solution A of 0.6M with deionized water;

[0032] Then use oxalic acid as a precipitating agent, and prepare oxalic acid solution B with a concentration of 1M with deionized water...

Embodiment 2

[0037] Example 2 Preparation of layered quaternary cathode material for lithium ion battery

[0038] according to figure 1 The process flow chart of the process, using soluble metal salts as raw materials to prepare the quaternary cathode material LiNi with a layered structure for lithium-ion batteries by co-precipitation 0.6 co 0.08 mn 0.24 Fe 0.08 o 2 , the method includes the following steps:

[0039] (1) Configuration solution:

[0040] First take the water-soluble nickel salt tetrahydrate nickel acetate (C 4 h 14 NiO 8 ), water-soluble diamond salt tetrahydrate cobalt acetate (C 4 h 14 CoO 8 ), water-soluble manganese salt tetrahydrate manganese acetate (C 4 h 14 MnO 8 ), water-soluble iron salt heptahydrate ferrous sulfate (FeSO 4 ·7H 2 (0), and be configured with deionized water to be the mixed metal solution A of 0.4M;

[0041] Then use oxalic acid as a precipitating agent, and prepare an oxalic acid solution B with a concentration of 0.5M with deioniz...

Embodiment 3

[0046] Example 3 Preparation of layered quaternary cathode material for lithium ion battery

[0047] according to figure 1 The process flow chart of the process, using soluble metal salts as raw materials to prepare the quaternary cathode material LiNi with a layered structure for lithium-ion batteries by co-precipitation 0.6 co 0.08 mn 0.24 Fe 0.08 o 2 , the method includes the following steps:

[0048] (1) Configuration solution:

[0049] First take the water-soluble nickel salt tetrahydrate nickel acetate (C 4 h 14 NiO 8 ), water-soluble diamond salt tetrahydrate cobalt acetate (C 4 h 14 CoO 8 ), water-soluble manganese salt tetrahydrate manganese acetate (C 4 h 14 MnO 8 ), water-soluble iron salt heptahydrate ferrous sulfate (FeSO 4 ·7H 2 (0), and be configured with deionized water to be the mixed metal solution A of 0.7M;

[0050] Then use oxalic acid as a precipitating agent, and prepare an oxalic acid solution B with a concentration of 0.8M with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com