Novel rice bran protein-based shortening substitute and application thereof in baked food

A rice bran protein, a new technology, applied in application, baking, food science and other directions, can solve the problems of single physicochemical properties, poor taste and flavor of oil gel, and achieve the effects of rich resources, strong foaming, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Accurately weigh 1.25g of rice bran protein and place it in 25g of pH 7 phosphate buffer solution to prepare a 5% rice bran protein solution; add 1.0% sodium alginate, 1.5% glycerin, 25% CaCl 2 Compound with rice bran protein; ultrasonicate the rice bran protein solution for 45 minutes with a power of 320W to completely expand the disulfide bonds of the rice bran protein, and let it stand for cooling; use a beater (German Braun HM5100) to beat the rice bran protein solution for 5 minutes with a power of 700W to prepare forming a rice bran protein foam; vacuum freeze-drying the rice bran protein foam to obtain a rice bran protein porous material. Accurately weigh 5% rice bran wax, add it to the vegetable oil, set the temperature at 90°C, and stir for 10 min with a magnetic stirrer at 500 rpm. The rice bran protein porous material was used as a template to adsorb liquid vegetable oil containing 5% rice bran wax, and after cooling, rice bran protein-based multi-structured ...

Embodiment 2

[0043] Accurately weigh 2.5g of rice bran protein and place it in 25g of 0.2mol / L NaCl phosphate buffer solution (pH 9) to prepare a 10% rice bran protein solution; add 2.0% sodium alginate, 2.0% glycerol, 30% CaCl 2 Compound with rice bran protein; ultrasonicate the rice bran protein solution for 30 minutes with a power of 400W to completely expand the disulfide bonds of the rice bran protein, and let it stand for cooling; beat the rice bran protein solution for 5 minutes with a beater (Germany Braun HM5100) with a power of 700W to prepare forming a rice bran protein foam; vacuum freeze-drying the rice bran protein foam to obtain a rice bran protein porous material. Accurately weigh 5% of candelilla wax, add it to the vegetable oil, set the temperature at 90° C., and stir for 10 min with a magnetic stirrer at 500 rpm. The rice bran protein porous material was used as a template to absorb liquid vegetable oil containing 5% candelilla wax, and after cooling, the rice bran prote...

experiment example 1

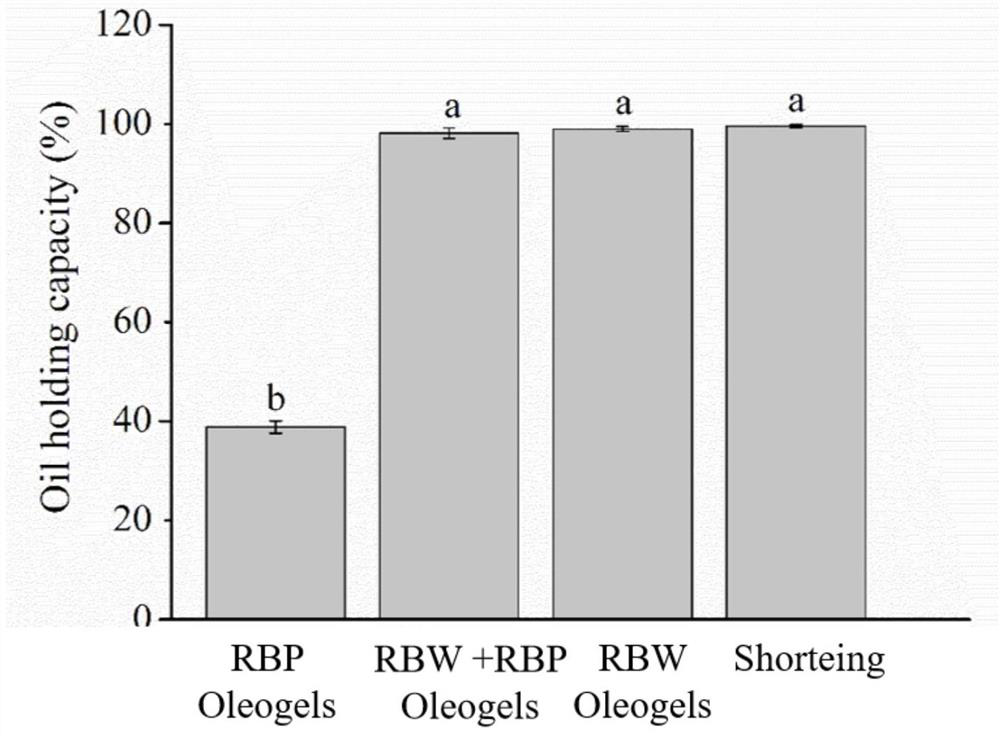

[0050] Experimental example 1 oil holding capacity test

[0051] The oil holding capacity of different oil-gel systems prepared in Example 1 and Comparative Examples 1-2 and commercially available shortening was tested.

[0052] Oil holding capacity test method: Weigh about 0.2g of oil gel sample, wrap it with a layer of oil-absorbing paper, put it into a 50mL centrifuge tube, and then centrifuge (5000rpm, 30min). Oil holding capacity (Oil holding capacity, OHC) is calculated as the ratio of the weight of oil retained in the oil gel after centrifugation to the total weight of oil in the sample (Manzocco et al., 2017), and the calculation formula is as follows:

[0053]

[0054] In the formula, m 0 is the weight of remaining oil in the oil gel after centrifugation, m 1 is the total weight of the oil before centrifugation.

[0055] Test results such as image 3 shown.

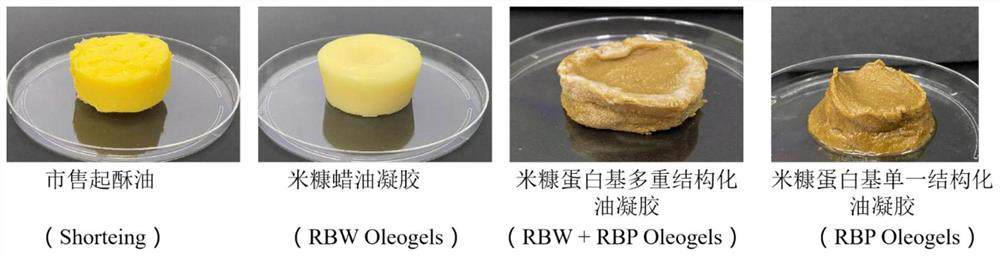

[0056] Depend on image 3 combine figure 2 The macrographs of the different oil gel systems and com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com