Cellulose nanofiber aerogel photo-thermal interface water evaporation material and preparation method thereof

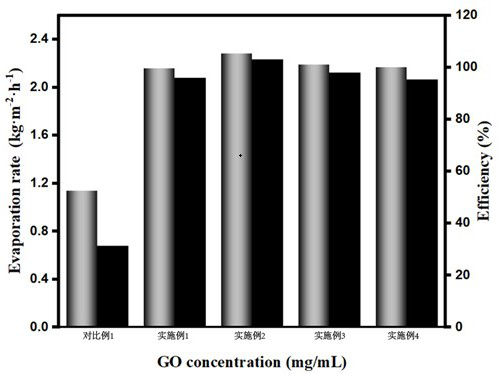

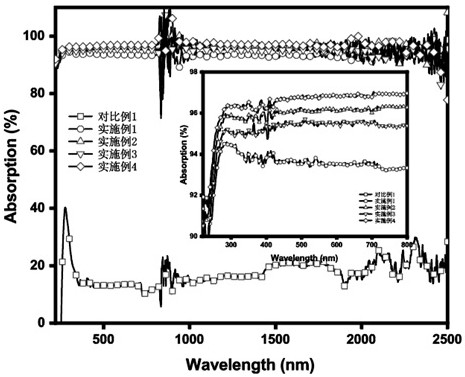

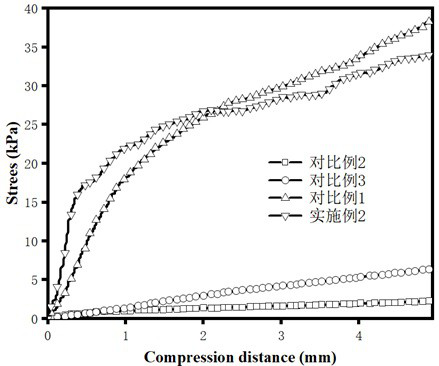

A technology of nanofiber and cellulose, which is applied in the field of photothermal water evaporation materials and its preparation, can solve the problems of poor water resistance, achieve low thermal conductivity, light weight, and improve the effect of photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiments of the present invention provide a cellulose nanofiber airgel photothermal interface water evaporation material and a preparation method thereof, the method comprising the following steps:

[0027] Step 1) Prepare 40 g of cellulose nanofiber dispersion with a mass fraction of 6%, put it in a beaker and stir at room temperature.

[0028] Step 2) preparation concentration is the graphene oxide solution of 1mg / mL, gets 40g graphene oxide solution, joins 0.72g polyvinyl alcohol in the graphene oxide solution and heats, after polyvinyl alcohol dissolves completely, pour into step (1 ) in the beaker, then add 0.72g butane tetracarboxylic acid and 0.72g sodium hypophosphite, and stir for 4-5 hours.

[0029] Step 3) Pour the uniformly dispersed mixture into a cylindrical mold with a diameter of 2.5cm and a height of 5cm, and place it in a refrigerator at -80±5°C for 10-12h, then put it in a temperature of -60±5°C , and freeze-dry in a freeze dryer with a vacuum deg...

Embodiment 2

[0032] Step 1) Prepare 40 g of cellulose nanofiber dispersion with a mass fraction of 6%, put it in a beaker and stir at room temperature.

[0033] Step 2) preparing a graphene oxide solution with a concentration of 2 mg / mL, taking 40 g of the graphene oxide solution, adding 0.72 g of polyvinyl alcohol to the graphene oxide solution for heating, after the polyvinyl alcohol is completely dissolved, pour into the step ( 1) into the beaker, then add 0.72g butane tetracarboxylic acid and 0.72g sodium hypophosphite, and stir for 4-5 hours.

[0034] Step 3) Pour the uniformly dispersed mixture into a cylindrical mold with a diameter of 2.5cm and a height of 5cm, and place it in a refrigerator at -80±5°C for 10-12 hours, then put it in a temperature of -60±5°C , and freeze-dry in a freeze dryer with a vacuum degree between 5-10Pa for 4-5 days to prepare the aerogel.

[0035] Step 4) Carry out the cross-linking reaction of the prepared airgel in an oven at 170±5°C for 10-15 minutes, ...

Embodiment 3

[0037] Step 1) Prepare 40 g of cellulose nanofiber dispersion with a mass fraction of 6%, put it in a beaker and stir at room temperature.

[0038] Step 2) preparation concentration is the graphene oxide solution of 3mg / mL, gets 40g graphene oxide solution, joins 0.72g polyvinyl alcohol in the graphene oxide solution and heats, after polyvinyl alcohol dissolves completely, pour into step (1 ) in the beaker, then add 0.72g butane tetracarboxylic acid and 0.72g sodium hypophosphite, and stir for 4-5 hours.

[0039] Step 3) Pour the uniformly dispersed mixture into a cylindrical mold with a diameter of 2.5cm and a height of 5cm, and place it in a refrigerator at -80±5°C for 10-12 hours, then put it in a temperature of -60±5°C , and freeze-dry in a freeze dryer with a vacuum degree between 5-10Pa for 4-5 days to prepare the aerogel.

[0040] Step 4) Carry out the cross-linking reaction of the prepared airgel in an oven at 170±5°C for 10-15 minutes, and then place the cross-linked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com