Method for preparing carbon/zeolite compound by utilizing fine coal gasification slag and application of carbon/zeolite compound

A coal gasification and compound technology, which is applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of complex technical route, unfavorable industrial synthesis, high cost, etc., and achieves simple and unique methods, good effects, The effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take Ningdong coal gasification fine slag and mix 2.5mol / L sodium hydroxide solution at 1kg:15L, and stir and react at 95°C for 6h. After the reaction was completed, filter directly while it was hot, wash the obtained solid with deionized water until neutral, and dry the solid product at 80° C. for 12 hours to obtain the carbon / zeolite composite.

[0025] Add 1kg of carbon / zeolite composite to 250L of 1000mg / L crystal violet aqueous solution, and statically adsorb for 3 hours at 30°C. The removal rate of crystal violet in water is as high as 99% as detected by ultraviolet absorptiometry.

[0026] The experimental results are as follows:

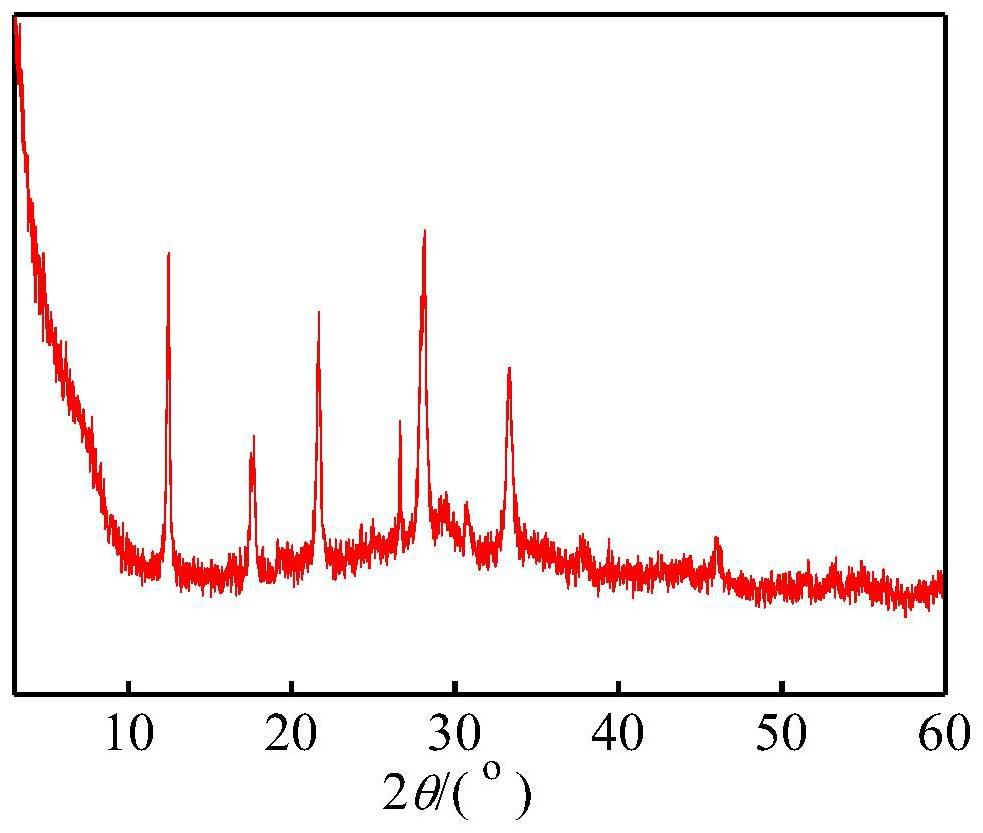

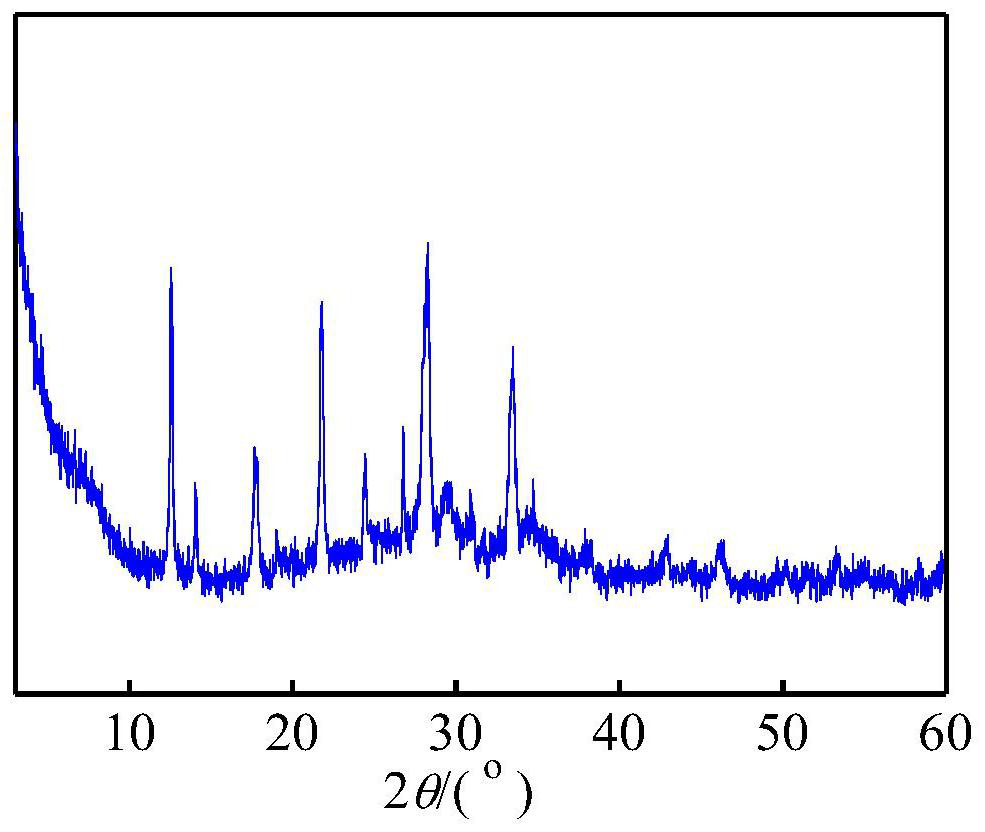

[0027] Such as figure 1 As shown, the phase of the carbon / zeolite composite has a typical NaP type zeolite, and the carbon is mainly amorphous.

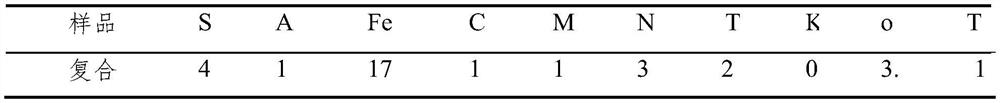

[0028] Table 1 shows the content of chemical components of coal gasification fine slag-based carbon / zeolite composites.

[0029] Table 1 The content of the chemical composition of the coal...

Embodiment 2

[0035] Take Ningdong coal gasification fine slag and mix 2.2mol / L sodium hydroxide solution at 1kg:14L, and stir and react at 100°C for 6h. After the reaction was completed, filter directly while it was hot, wash the obtained solid with deionized water until neutral, and dry the solid product at 90°C for 11 hours to obtain the carbon / zeolite composite.

[0036] Add 1kg of carbon / zeolite composite to 125L of 1500mg / L crystal violet aqueous solution, and statically adsorb for 2 hours at 30°C. The removal rate of crystal violet in water is as high as 99% as detected by ultraviolet absorptiometry.

Embodiment 3

[0038] Take Ningdong coal gasification fine slag and mix 2.8mol / L sodium hydroxide solution at 1kg:16L, and stir and react at 90°C for 8h. After the reaction was completed, filter directly while it was hot, wash the obtained solid with deionized water until neutral, and dry the solid product at 60° C. for 24 hours to obtain the carbon / zeolite composite.

[0039] Add 0.5kg of carbon / zeolite composite to 125L of 1500mg / L crystal violet aqueous solution, and statically adsorb at 30°C for 2.5h. The removal rate of crystal violet in water is as high as 99% as detected by ultraviolet absorptiometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com