Coal slime non-quantification process for classifying and selecting viscous and wet power coal

A thermal coal and coal slime technology, applied in the direction of solid separation, chemical instruments and methods, grids, etc., can solve the problems of easy adhesion on the inner wall of coal bunker, economic loss of coal preparation plant, low raw coal selection rate, etc., and achieve the realization of The effects of non-quantification of coal slime discharge, improvement of selection rate, and increase of clean coal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

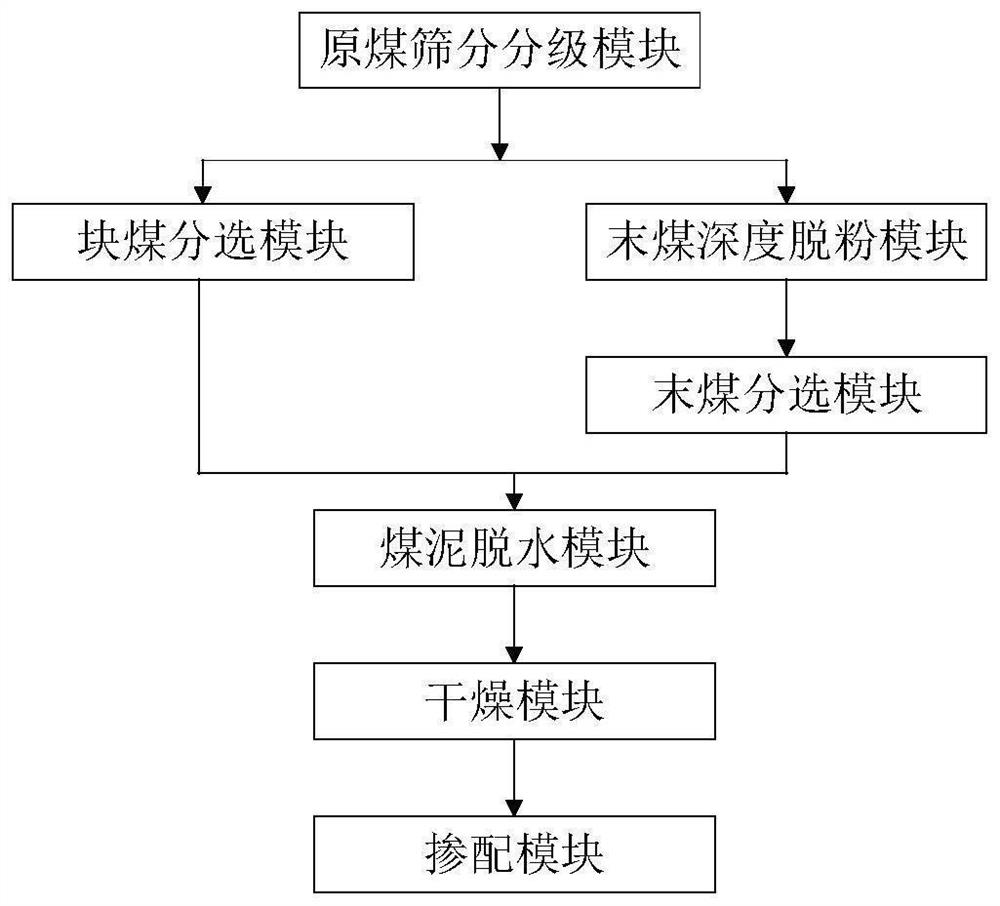

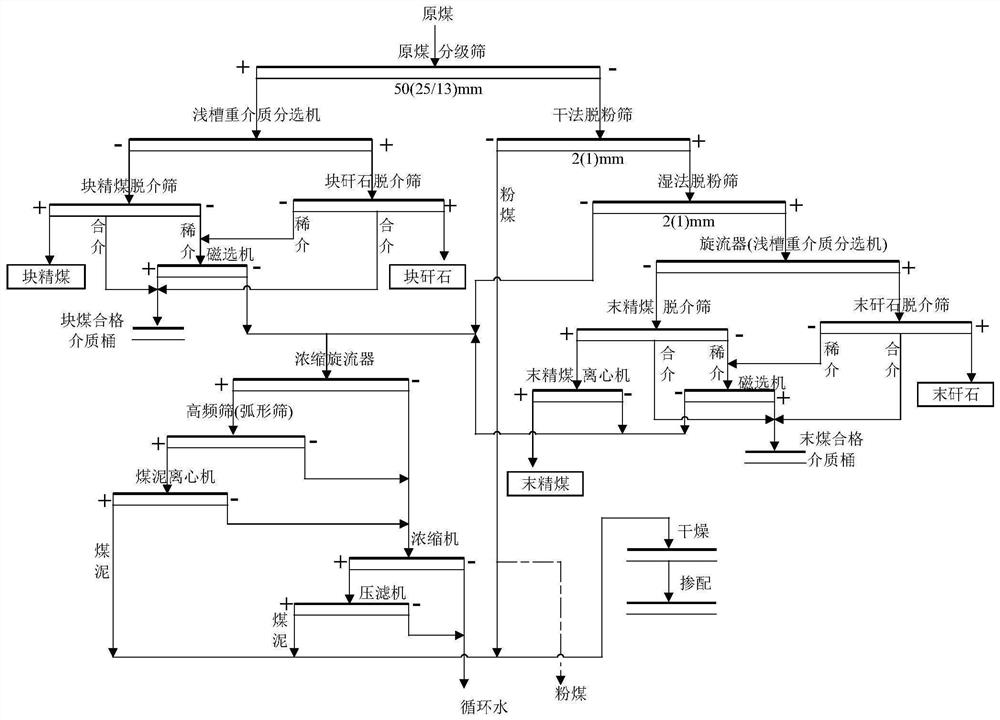

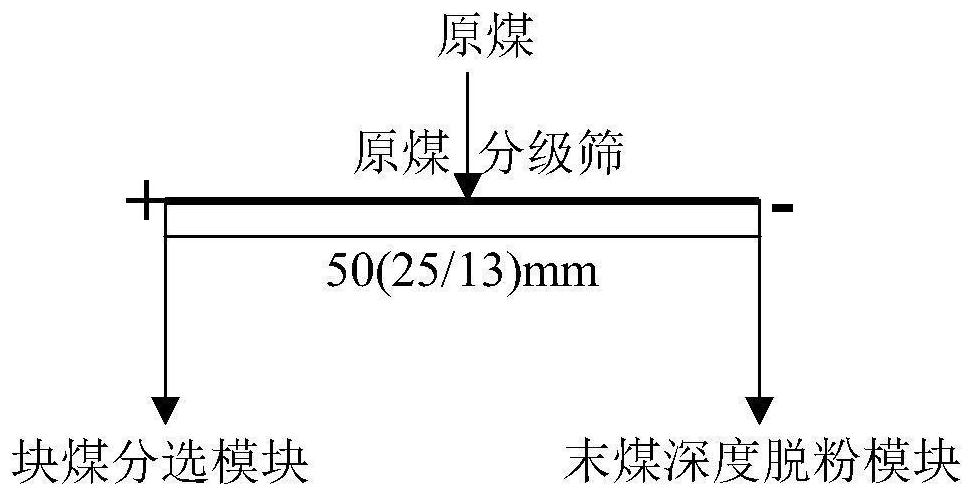

[0042] Raw coal screening and grading module: such as image 3 As shown, the raw coal is classified by the raw coal grading sieve, the material larger than the sieve size becomes the oversize material, and the material smaller than the sieve size becomes the undersize material, the oversize material enters the lump coal separation module, and the undersize material enters the fine coal depth Powder removal module. The screen surface can be a rigid screen surface, or a rigid-flexible coupling elastic screen surface, and the mesh size of the raw coal grading screen can be selected from one of 50mm, 25mm, and 13mm;

[0043] Lump coal separation module: such as Figure 4 As shown, the material entering this module is the raw coal > 50 (or 25 or 13) mm on the raw coal sieve in the raw coal sieving and grading module, and the > 50 (or 25 or 13) mm raw coal enters the lump coal shallow groove for dense medium separation Sorting is carried out in the sorting machine, and the light p...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that the drying module and the blending module, other modules are all the same as in embodiment 1, and the specific implementation methods are as follows:

[0053] Drying module: When the moisture content of the pulverized coal entering the fine coal drying module is low, it can be directly sold as a product without drying; the coal slime from the coal slime dehydration module enters the drying module for drying. Crushing is carried out, and then dried, and the dried product enters the blending module. The drying equipment used in the drying module may be one of a rotor dryer and a rotary drum dryer.

[0054] Blending module: The coal slime from the drying module is transported by the belt, and all of it is blended into lump clean coal and fine coal products as products for sale, or directly blended into pulverized coal as products for sale; a part of it can also be blended into lump coal Part of clean coal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com