Large-size molybdenum target material and preparation method and application thereof

A large-scale, molybdenum target technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of unsatisfactory molybdenum target purity, increased target demand, long length, etc. Diversity control of particles, the effect of meeting the requirements of sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

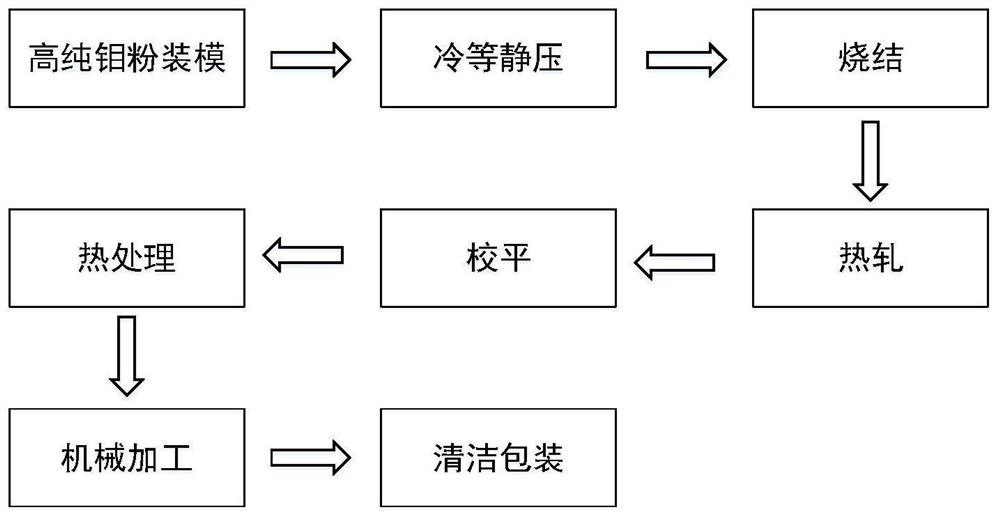

[0057] This embodiment provides a large-size molybdenum target and its preparation method. The preparation method is as follows figure 1 shown, including the following steps:

[0058] (1) High-purity molybdenum powder molding: put high-purity molybdenum powder with a purity of 99.96% and a potassium content of 18ppm into rubber sleeves, roll, vibrate, then repeatedly roll and vibrate to make it smooth, and then seal;

[0059] (2) Cold isostatic pressing: four-stage pressurization and four-stage pressure relief are adopted; the pressure of the cold isostatic pressing is 170-250MPa, and the time is 45min;

[0060] (3) Sintering: Sinter the molybdenum target blank after cold isostatic pressing at a temperature of 1900° C. for 45 hours; the density of the sintered molybdenum target blank is 10.0 g / cm 3 ;The overall thickness deviation is 3mm, and the thickness difference between the two sides is 1.5mm;

[0061] (4) Hot rolling: the sintered molybdenum target blank is sequentiall...

Embodiment 2

[0067] This embodiment provides a large-size molybdenum target and its preparation method, the preparation method comprising the following steps:

[0068] (1) High-purity molybdenum powder molding: put high-purity molybdenum powder with a purity of 99.97% and a potassium content of 20ppm into rubber sleeves, roll, vibrate, then repeatedly roll and vibrate to level off, and then seal;

[0069] (2) Cold isostatic pressing: four-stage pressurization and four-stage pressure relief are adopted; the pressure of the cold isostatic pressing is 170-250MPa, and the time is 60min;

[0070] (3) Sintering: Sinter the molybdenum target blank after cold isostatic pressing at a temperature of 1800°C for 60h; the density of the sintered molybdenum target blank is 9.8g / cm 3 ;The overall thickness deviation is 4mm, and the thickness difference on both sides is 2mm;

[0071] (4) Hot rolling: the molybdenum target blank after the sintering is subjected to the second hot rolling treatment and the ...

Embodiment 3

[0077] This embodiment provides a large-size molybdenum target and its preparation method, the preparation method comprising the following steps:

[0078] (1) High-purity molybdenum powder molding: put high-purity molybdenum powder with a purity of 99.96% and a potassium content of 20ppm into rubber sleeves, roll, vibrate, roll repeatedly, shake repeatedly, and then seal;

[0079] (2) Cold isostatic pressing: four-stage pressurization and four-stage pressure relief are adopted; the pressure of the cold isostatic pressing is 170-250MPa, and the time is 30min;

[0080](3) Sintering: Sinter the molybdenum target blank after cold isostatic pressing at a temperature of 2000°C for 30h; the density of the sintered molybdenum target blank is 10.1g / cm 3 ;The overall thickness deviation is 2mm, and the thickness difference on both sides is 2mm;

[0081] (4) Hot rolling: the molybdenum target blank after the sintering is subjected to the second hot rolling treatment and the third hot ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com