Method for preparing single crystal 85Cu-15Sn alloy through spiral crystal selection

An 85cu-15sn, spiral selection technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of poor plasticity, serious segregation of copper-tin alloys, easy to break cores, etc., to eliminate crack propagation. , Excellent comprehensive performance, the effect of eliminating lateral grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 80wt.% of Cu block and 20wt.% of Sn particles in turn, use 200# sandpaper to polish the oxide skin on the surface of the copper block, then put the surface-treated copper block into the ultrasonic cleaner, and add Wash with an appropriate amount of absolute ethanol for 20 minutes. After cleaning, take out the copper block and dry it;

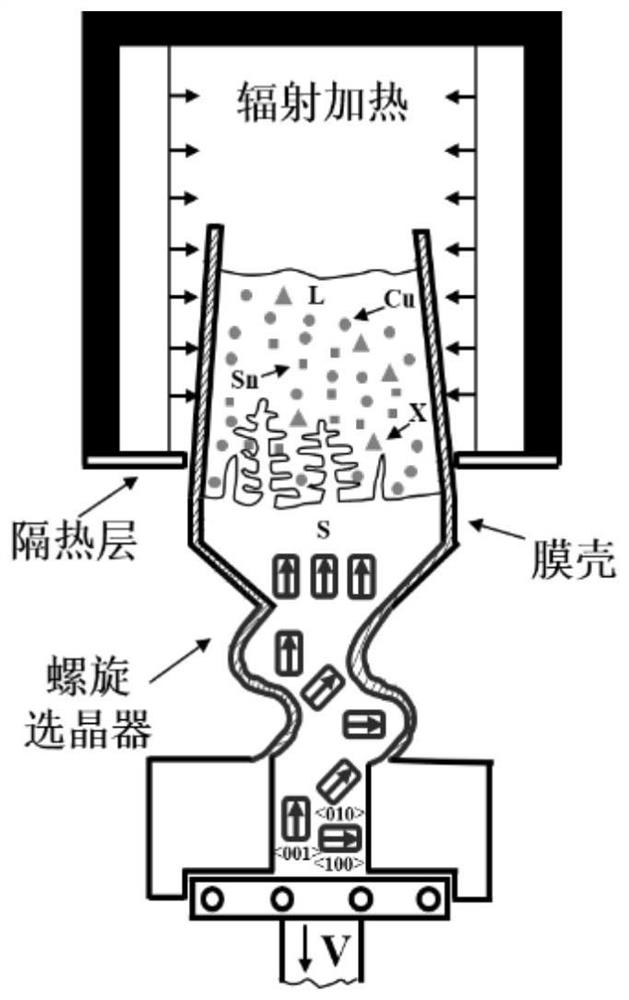

[0032] Put the weighed materials into the induction coil of the directional solidification furnace in turn, check whether the casting position of the coil is aligned with the guide tube, fix the spiral crystal selector and check whether the guide tube and the spiral crystal selector are aligned, figure 1 The crystal selection principle of the crystal selector is shown, and finally the furnace door is closed;

[0033] Use mechanical pump, Roots pump and diffusion pump to vacuum the furnace to 6×10 -3 Pa, start the induction power supply to heat the material, and the power of the power supply increases by 1KW every 10 minutes. After ...

Embodiment 2

[0036] Weigh 83wt.% of Cu block and 17wt.% of Sn particles in turn, use 200# sandpaper to polish the oxide skin on the surface of the copper block, then put the surface-treated copper block into the ultrasonic cleaner, and add Clean with an appropriate amount of absolute ethanol for 25 minutes. After cleaning, take out the copper block and dry it;

[0037] Put the weighed materials into the induction coil of the directional solidification furnace in turn, check whether the casting position of the coil is aligned with the guide tube, fix the spiral crystal selector and check whether the guide tube and the spiral crystal selector are aligned, figure 1 The crystal selection principle of the crystal selector is shown, and finally the furnace door is closed;

[0038] Use mechanical pump, Roots pump and diffusion pump to vacuum the furnace to 6×10 -3 Pa, start the induction power supply to heat the material, the power of the power supply is increased by 2KW every 20min, and when th...

Embodiment 3

[0041]Weigh 86wt.% of Cu block and 14wt.% of Sn particles in turn, use 200# sandpaper to polish the oxide skin on the surface of the copper block, then put the surface-treated copper block into the ultrasonic cleaner, and add Clean with an appropriate amount of absolute ethanol for 30 minutes. After cleaning, take out the copper block and dry it;

[0042] Put the weighed materials into the induction coil of the directional solidification furnace in turn, check whether the casting position of the coil is aligned with the guide tube, fix the spiral crystal selector and check whether the guide tube and the spiral crystal selector are aligned, figure 1 The crystal selection principle of the crystal selector is shown, and finally the furnace door is closed;

[0043] Use mechanical pump, Roots pump and diffusion pump to vacuum the furnace to 6×10 -3 Pa, start the induction power supply to heat the material, the power of the power supply is increased by 3KW every 30min, and when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com