Exterior wall construction joint leakage repairing process

A technology for construction joints and exterior walls, which is applied in the field of building crack repair, can solve the problems of affecting bearing capacity, durability and impermeability, poor impermeability at cracks, and inefficient repair process, so as to reduce the generation of micro cracks, Improved mechanical properties and low overall viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0057] A plugging grouting material, which is composed of A component and B component, and its components and dosage are shown in Table 1. The specific preparation steps are as follows:

[0058] a. Stir component A at 1500r / min for 30 minutes to obtain a homogenized slurry for later use, wherein the alkali metal oxide in component A is magnesium oxide, and the alkali metal hydroxide is magnesium hydroxide;

[0059] b. First add 15% of the total weight of component B to the mixing homogenate, and stir and mix at 1500r / min for 5-15min, then raise the temperature to 65°C, add the rest of component B, and mix at 2500r / min 40min, the plugging grouting material can be prepared;

[0060] Wherein, the ether crosslinking agent in component B is glycerol triglycidyl ether; the accelerator is cobalt naphthenate; and the initiator is potassium persulfate.

preparation example 2-6

[0062] A plugging grouting material, which differs from Preparation Example 1 in that its components and their corresponding weights are shown in Table 1.

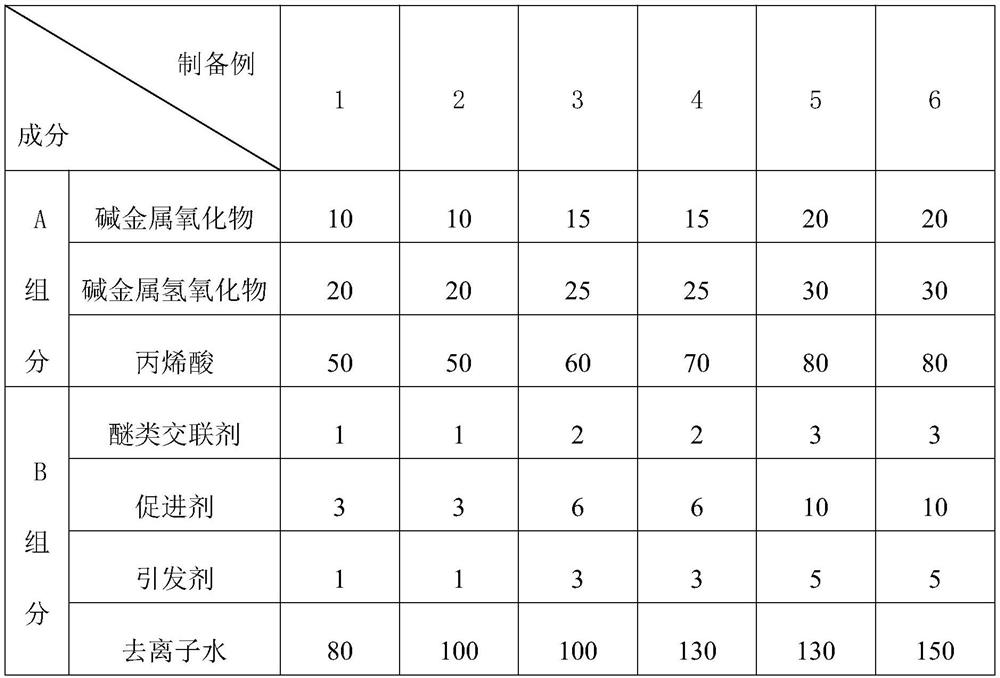

[0063] Each component and its weight (kg) of plugging grout in Table 1 Preparation Example 1-6

[0064]

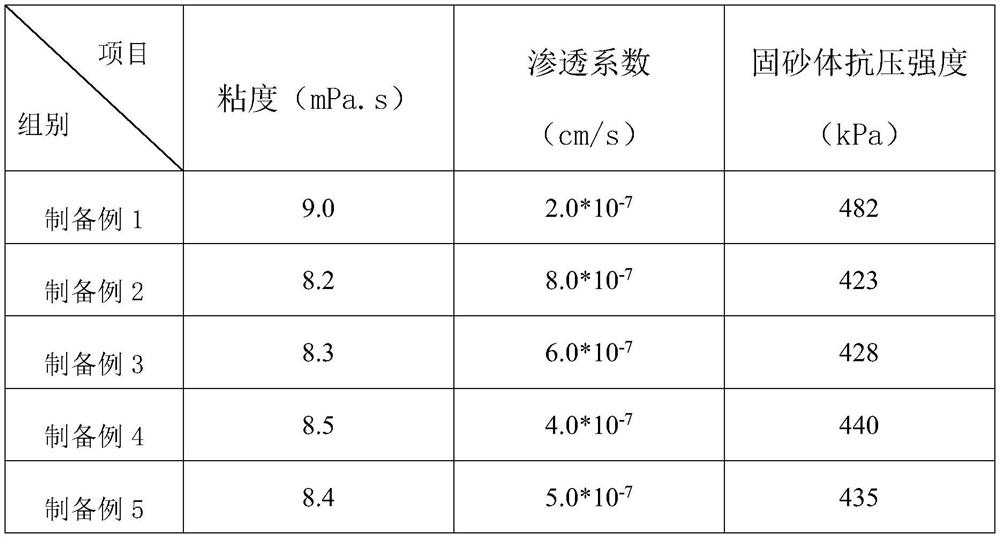

[0065] Take the plugging grouting material prepared in the above application examples 1-6, and test its viscosity, permeability coefficient and sand-fixing body compressive strength according to the above measurement standards, and take the average value of the test results and record them in the table below.

[0066]

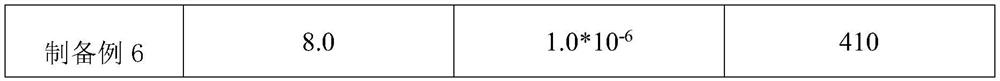

[0067]

[0068] It can be seen from the above table that the plugging grouting material prepared in Preparation Example 1-6 has a low overall viscosity of 8.0-9.0mPa.s; strong permeability and a permeability coefficient of 2.0*10 -7 -1.0*10 -6 ; It also has excellent elasticity and deformation resistance, and its compressive strength of sand consolidation body is as high as 410-482kPa;

[006...

preparation example 7

[0071] A kind of plugging grouting material, and the difference of preparation example 1 is that each parameter condition in its preparation step is as follows:

[0072] a. First, stir component A at 1000r / min for 15 minutes, and then mix and homogenize it for later use;

[0073] b. First add 10% of the total weight of component B to the mixing homogenate, and stir and mix at 1000r / min for 5min, then raise the temperature to 35°C, add the rest of component B, and mix at 2000r / min for 30min, The plugging grout can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com