Thermodynamic system for improving fuel gas-steam combined cycle performance and working method thereof

A combined cycle and thermal system technology, applied in steam engine installations, gas turbine installations, machine operation modes, etc., can solve problems such as insufficient utilization of heat, inconvenient cycle performance, inability to do anything, etc., to improve energy utilization efficiency, The effect of increasing gas density and avoiding waste of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

[0028] Gas turbines are classified according to application fields, mainly including heavy-duty gas turbines for ground power generation or traction, and aeroengines for aviation propulsion. The technology of the present invention mainly relates to heavy-duty gas turbines for power generation on the ground.

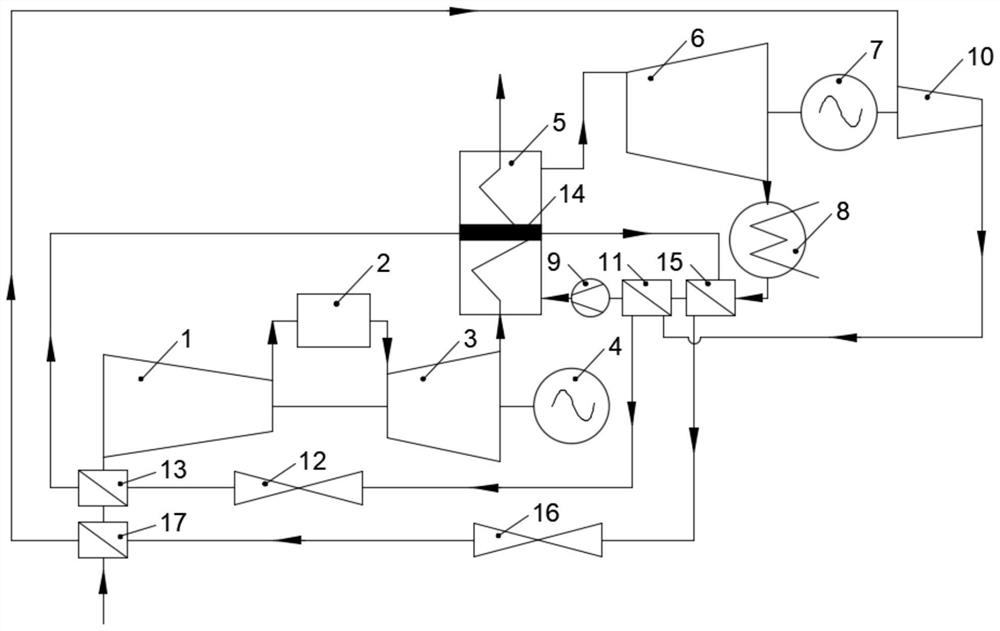

[0029] figure 1 The thermodynamic system for improving the performance of the gas-steam combined cycle of the present invention includes a compressor 1, a combustion chamber 2, a gas turbine 3, a gas turbine generator 4, a waste heat boiler 5, a steam turbine 6, a steam turbine generator 7, water Steam condenser 8, boiler feed water pump 9, compressor 10, mechanical refrigeration condenser 11, mechanical refrigeration throttle valve 12, mechanical refrigeration evaporator 13, abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com