Porous adsorption material based on reutilization of alcohol-soluble waste in production process of polyphenyl ether and synthesis method of porous adsorption material

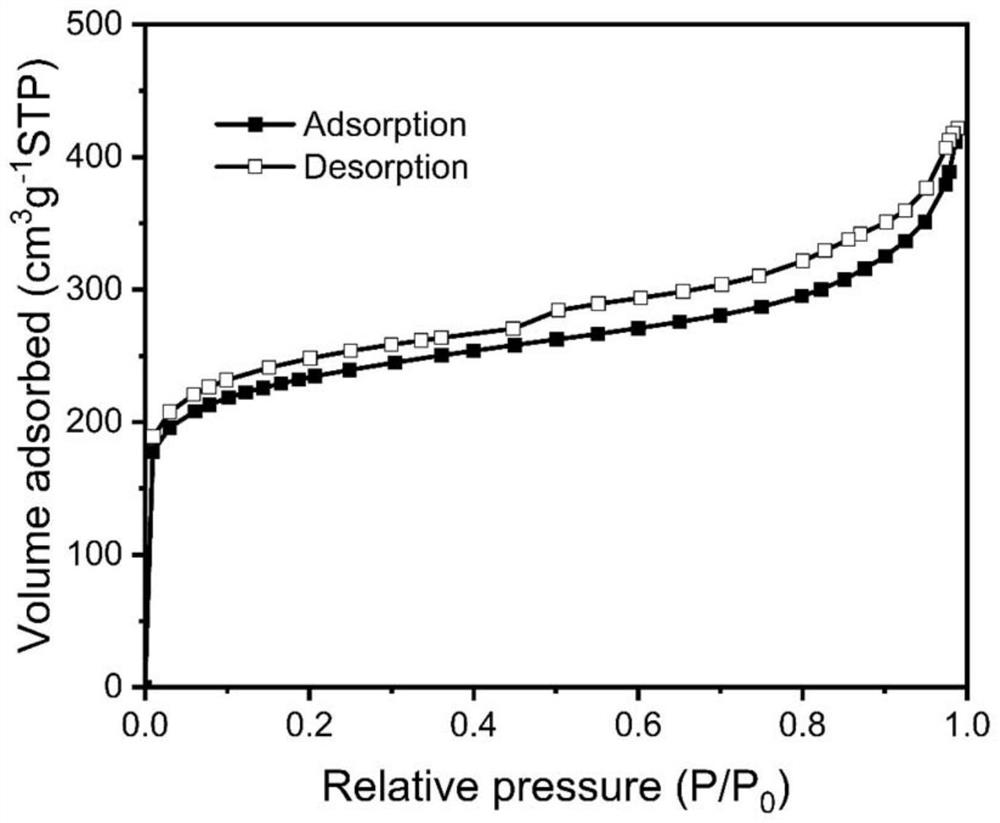

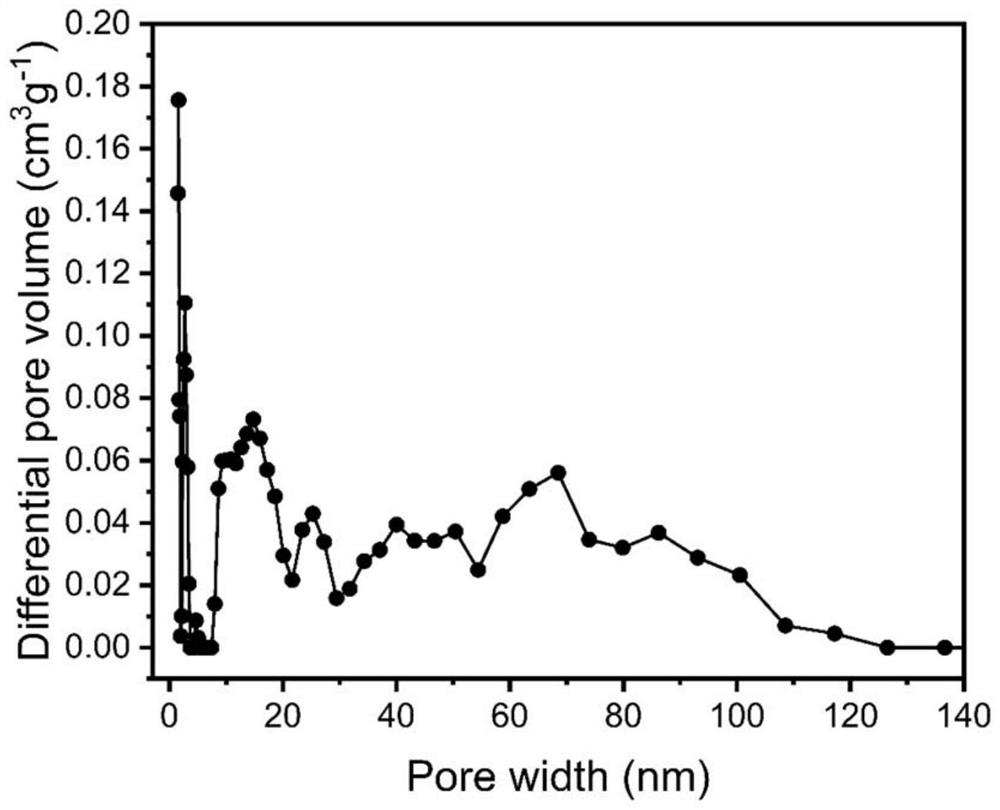

A porous adsorption material and production process technology, applied in separation methods, other chemical processes, chemical instruments and methods, etc., can solve the problems of easily polluting the environment, increasing the toxicity of asphalt, etc., achieving large micropore volume, excellent performance, high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add purification waste (1g), 1,2-dichloroethane (20ml), anhydrous ferric chloride (1.3517g, 0.0083mol) to the reactor in turn, stir until fully dissolved, then add p-dichlorobenzyl (0.7294 g, 0.0042 mol), nitrogen-vacuum pumping 3 times, nitrogen bubbling for 15 min, and reacting at 60°C for 12 hours.

[0028] After the reaction, the brown solid product was obtained by suction filtration under reduced pressure, washed with methanol three times, and extracted with methanol in a Soxhlet extractor for 24 hours. Finally, vacuum-dry at 80°C for 24 hours to obtain the final product.

Embodiment 2

[0030] Add purification waste (1g), 1,2-dichloroethane (20ml), anhydrous ferric chloride (6.7583g, 0.0417mol) to the reactor in turn, stir until fully dissolved, then add p-dichlorobenzyl (3.6471 g, 0.0208 mol), nitrogen-vacuum pumping 3 times, nitrogen bubbling for 15 minutes, and reacting at 80°C for 36 hours.

[0031] After the reaction, the brown solid product was obtained by suction filtration under reduced pressure, washed with methanol three times, and extracted with methanol in a Soxhlet extractor for 24 hours. Finally, vacuum dry at 80°C for 24h to obtain the final product

Embodiment 3

[0033] Add purification waste (1g), 1,2-dichloroethane (20ml), anhydrous ferric chloride (4.055g, 0.025mol) to the reactor in turn, stir until fully dissolved, then add p-dichlorobenzyl (2.1883 g, 0.0125 mol), nitrogen gas-vacuum pumping 3 times, nitrogen gas bubbling for 15 min, and reaction at 80°C for 24 hours.

[0034] After the reaction, the brown solid product was obtained by suction filtration under reduced pressure, washed with methanol three times, and extracted with methanol in a Soxhlet extractor for 24 hours. Finally, vacuum-dry at 80°C for 24 hours to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com