Boiling heating method and boiling heating furnace for preparing zirconium tetrachloride

A technology of zirconium tetrachloride and heating method, applied in zirconium halide and other directions, can solve the problems of small production capacity, poor economic benefit and low electric heating efficiency of a single set of devices, and achieve the effects of simple structure, reduced raw material cost and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

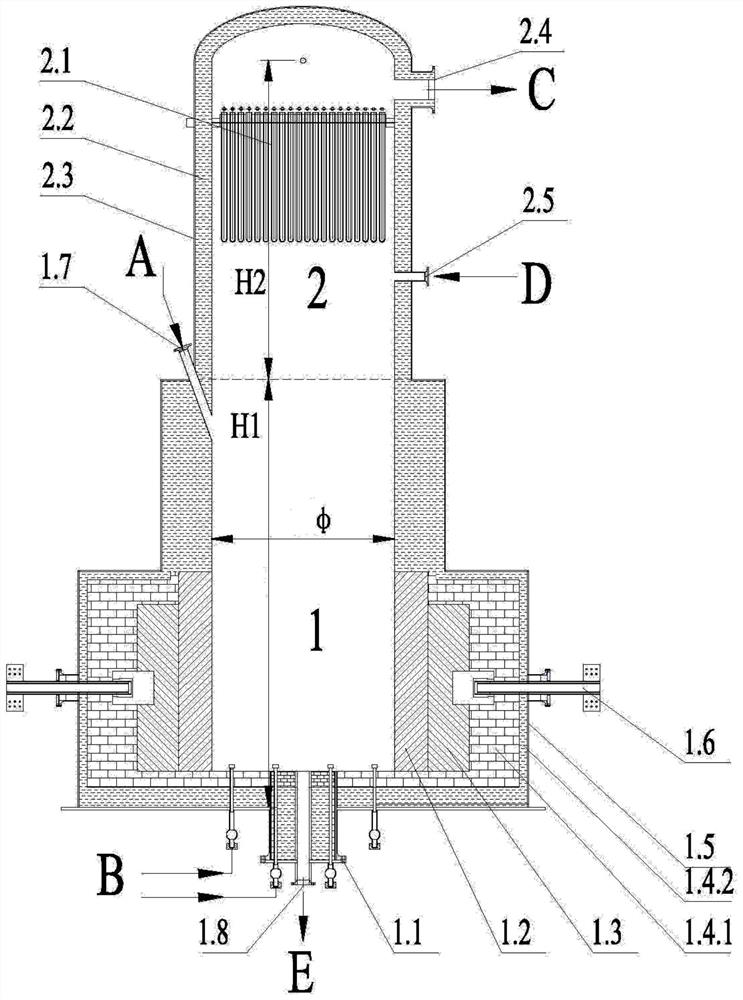

[0066] A fluidized heating furnace for preparing zirconium tetrachloride, comprising: a fluidized reaction section 1 and a filtration and purification section 2, the fluidized reaction section 1 is located at the lower part of the fluidized heating furnace device, and the filtration and purification section 2 is located at the upper part of the fluidized heating furnace device. The reaction section 1 and the filtration purification section 2 are connected by welding;

[0067] The fluidized reaction section includes: chlorine distributor 1.1, graphite heat-conducting layer 1.2, carbon heating layer 1.3, high-silicon refractory brick 1.4.1 for the first refractory and heat-insulating layer, silicon-aluminum system for the first refractory and heat-insulating layer Refractory castable material 1.4.2, fluidized reaction section furnace shell 1.5, conductive electrode 1.6, feeding pipe 1.7 and slag discharge pipe 1.8;

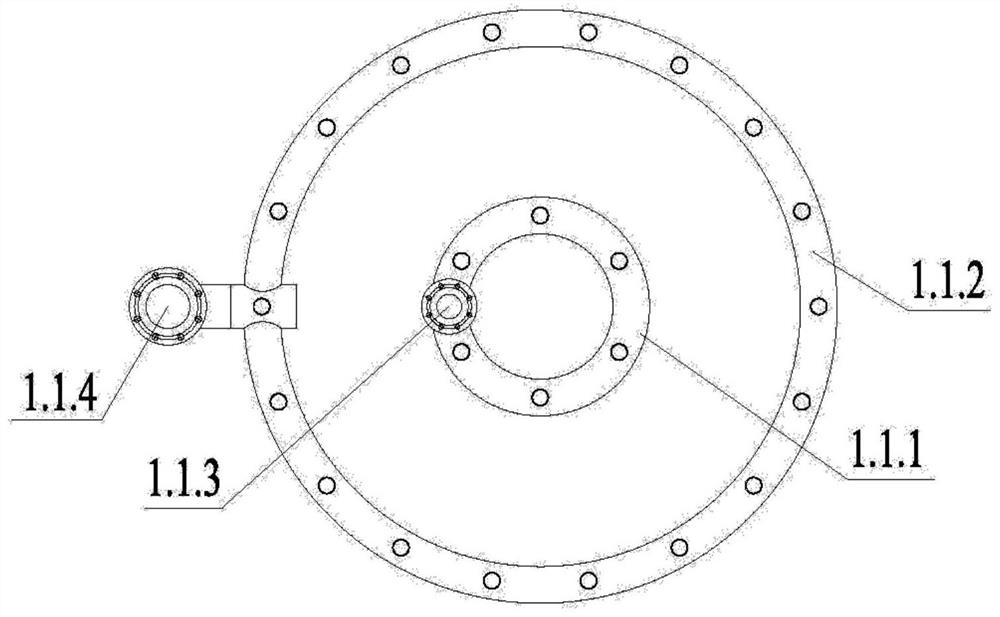

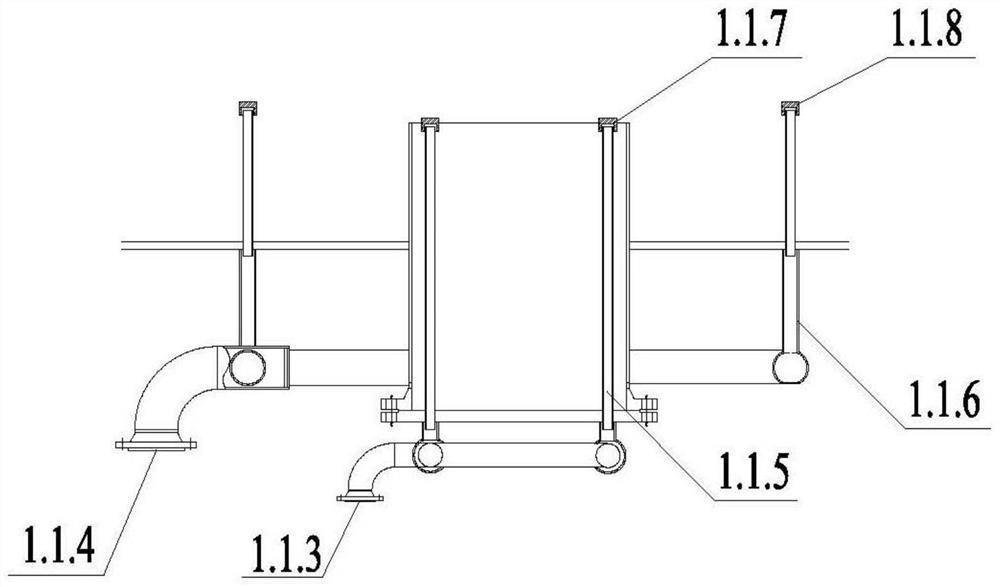

[0068] The above-mentioned chlorine distributor 1.1 includes: ...

Embodiment 2

[0098] A kind of fluidized heating furnace for preparing zirconium tetrachloride, the schematic diagram of its device structure is shown in figure 1 , including a fluidized reaction section 1 and a filtration and purification section 2, the fluidization reaction section 1 is located at the lower part of the fluidized heating furnace, and the filtration and purification section 2 is located at the upper part of the fluidized heating furnace, and the fluidized reaction section 1 and the filtration and purification section 2 are fixed and sealed by welding.

[0099] Among them, the fluidized reaction section 1 includes a furnace shell 1.5 of the fluidized reaction section, the furnace shell 1.5 of the fluidized reaction section is divided into an upper part and a lower part, and the inner wall of the upper part is provided with a silicon-aluminum series refractory castable material 1.4 of the first refractory heat insulation layer .2, the inner side of the lower part is sequential...

Embodiment 3

[0124] A kind of boiling furnace for preparing zirconium tetrachloride, same as embodiment 1.

[0125] A boiling heating method for preparing zirconium tetrachloride, adopting the boiling heating furnace for preparing zirconium tetrachloride described in embodiment 1, comprises the following steps:

[0126] (1) Send electricity to the boiling heating furnace to bake the furnace, and then start the conductive electrode to keep the temperature in the furnace heated to 790°C;

[0127] (2) According to the ratio, weigh the raw material zircon sand and zirconium carbide, and weigh the carbonaceous reducing agent at the same time, and add it into the fluidized reaction section of the boiling heating furnace through the feeding pipe; according to the mass ratio, zircon sand: zirconium carbide: carbonaceous reducing agent = 72:21:5;

[0128] (3) Continue heating. When the temperature of the material in the furnace reaches 850°C, add preheated chlorine gas into the boiling heating fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com